Sanitary mini olive oil centrifuge for olive oil separation Supplier & manufacturers | Shenzhou

Shenzhou Group can provide a complete set of olive oil production lines.If you need olive machines,you can contact Shenzhou Group.

Three-phase Decanter Centrifuge

Three-phase decanter centrifuge can be used in following cleaning, solid remove and impurity remove 3 phase separation field: tar, pesticide, oil filed recovered oil, used oil, waste oil & fat from restaurant, palm oil, oil tank cleaning, oil refining sludge, oil station cleaning sludge, olive oil, orange oil, gas floating sludge, food waste sludge

Three-phase Decanter Centrifuge Features:

1. Reasonable structure, convenient for operation

2. Can be used for two-phase & three-phase separation

3. Suitable for various application environments

Operation Principle of Three-phase Decanter Centrifuge:

Similar with two-phase decanter centrifuge operation principle, under the centrifugal force the feeding material can be divided into three relative stable layers. From the bowl inside wall there will be solids phase layer, heavy liquid phase and light liquid phase.

The solids phase layer is pushed to bowl small-end part by conveyor and discharged from solid outlet. The heavy liquid phase and light liquid phase are delivered to bowl big-end part and discharged separately from two different outlets.

It can reach three-phase separation.

Separation Type:

Solid -liquid –liquid

Liquid -liquid-solid

Liquid-solid-liquid

Applications Three-phase Decanter Centrifuge:

Three-phase decanter centrifuge can be used in following cleaning, solid remove and impurity remove 3 phase separation field: tar, pesticide, oil filed recovered oil, used oil, waste oil & fat from restaurant, palm oil, oil tank cleaning, oil refining sludge, oil station cleaning sludge, olive oil, orange oil, gas floating sludge, food waste sludge.

Typical Applications of Three-phase Decanter Centrifuge:

Oil sludge treatment, animal/plant fat & oil extraction, starch & vital gluten separation, fish oil, albumen and fish meal separation in fish oil field

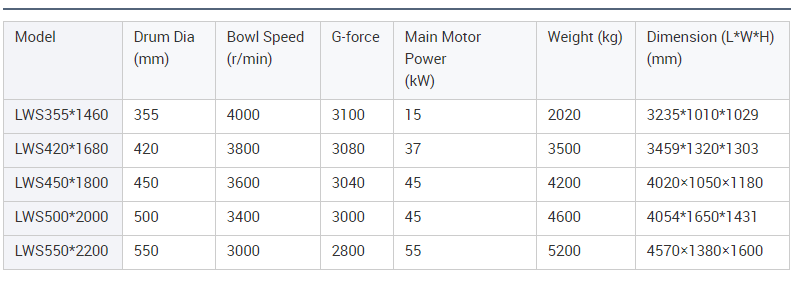

Three phase decanter centrifuge parameter:

Our Company undertakes equipment selection, design and manufacturing according to material data and actual demands of users. We warmly welcome users to visit our Company for field investigation, technical exchange and long-term cooperation.

● A wide range of models to choose from ● Provide turnkey project ● High degree of automation, easy to manage ● Fully enclosed operation, humanized operating environment.

● Highly adaptable to sludge and has a large treatment capacity ● Adopting advanced control system and high quality electrical components, which can reduce the consumption of chemicals and loss of electrical energy ● The floor space of the machine is about 2/3 smaller than traditional filtration equipment.

● Dual Motor Dual Frequency Conversion Common DC Busbar Technology - Energy Saving ● Constant Torque Control Technology - Stable ● Vortex Spiral Discharge Port-High Capacity ● Variable Pitch Technology-Lower Solid-Phase Water Content ● YG6, YG8 Carbide, SAF2205 Duplex Stainless Steel-Good Wear Resistance