Shenzhou - model horizontal scraper discharging peeler industrial centrifuge

We use chemically-stable and environmental-friendly raw materials to manufacture the model GK1050 horizontal scraper discharging peeler industrial centrifuge machine.Therefore, it is excellent in stable performance and totally safe for users. In addition, it is excellent performance making it highly practical in many fields and valuable.

The peeler centrifuge is a solid-liquid separation equipment designed and produced by Doing Holdings-Henan Jinrui according to the characteristics of cassava starch. The peeler centrifuge is used for the dehydration of starch milk in cassava starch production. After dehydration, wet cassava starch with a moisture content of about 38% can be obtained.

Peeler centrifuge being installed

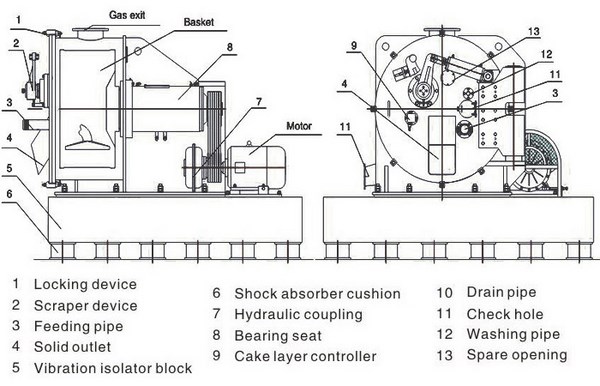

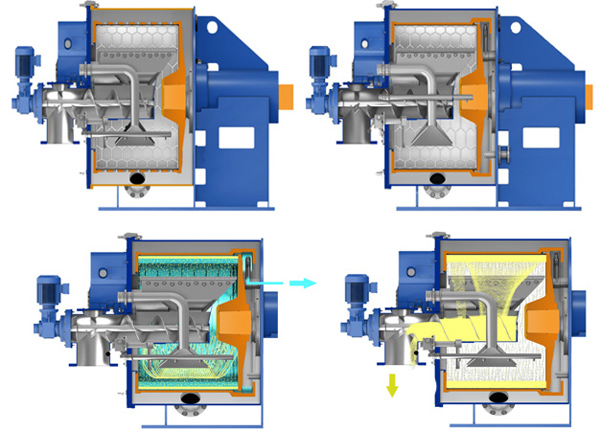

The specific work process of the peeler centrifuge is as follows: before the cassava starch slurry enters the peeler centrifuge, in order to ensure the fluidity of the cassava starch slurry, firstly pour water into the peeler centrifuge. Then the cassava starch slurry enters the peeler centrifuge, and the drum begins to continuously rotate at a high speed. Under the action of centrifugal force, the cassava starch slurry removes water and the water is discharged from the filter holes. The starch stays on the screen in the drum and the cassava starch cake is automatically scraped off by the scraper in the drum. After the discharging is completed, in order to ensure the permeability of the screen, the backflushing device will automatically start to clean the screen. A complete dehydration process only takes 3-4 minutes.

There are two main types of peeler centrifuges available for you: ordinary peeler centrifuge and siphon peeler centrifuge. In general, if the specifications are the same, the processing capacity of the siphon peeler centrifuge is about twice that of the ordinary peeler centrifuge. Moreover, the siphon peeler centrifuge has lower moisture after dehydration.After cassava starch is processed by siphon peeler centrifuge, its dehydration effect is two percentage points lower than the ordinary peeler centrifuge.

The peeler centrifuge has high dehydration rate, stable operation and no noise, and can achieve continuous dehydration for a long time. It is an ideal choice for large and medium-sized starch production plants. If you want to know more details about cassava starch dewatering machine peeler centrifuge, please leave us your contact information.

Peeler centrifuge parameters:

| With Siphon | GKH800-N | GKH1250-N | GKH1600-N | GKH1800-N |

| Inner Diameter of Basket (mm) | 800 | 1250 | 1600 | 1800 |

| Length of Basket (mm) | 450 | 630 | 1000 | 1250 |

| Rotary Speed (r/min) | 1550 | 1200 | 950 | 800 |

| G force (Fr) | 1070 | 1006 | 808 | 645 |

| Max Loading (kg) | 150 | 455 | 1000 | 1660 |

| Max Volume (L) | 100 | 372 | 830 | 1325 |

| Filter Area (m2) | 1.13 | 2.47 | 5 | 7 |

| Motor Power (kW) | 45 | 75 | 132 | 200 |

| Dimension (mm)(L×W×H) | 2030*1960*1530 | 2260*1840*1810 | 4050*2550*2300 | 5800*2840*2600 |

| Weight (kg) | 5500 | 6800 | 16500 | 24900 |

| Without Siphon | GK800-NB | GK1250-NB | GK1600-NA | |

| Inner Diameter of Basket (mm) | 800 | 1250 | 1600 | |

| Length of Basket (mm) | 450 | 600 | 800 | |

| Rotary Speed (r/min) | 1550 | 1200 | 950 | |

| G force (Fr) | 1070 | 1006 | 800 | |

| Max Loading (kg) | 130 | 400 | 850 | |

| Max Volume (L) | 100 | 310 | 660 | |

| Motor Power (kW) | 37 | 55 | 110 | |

| Dimension (mm)(L×W×H) | 2480*1650*1300 | 3100*2070*1775 | 3885*2726*2220 | |

| Weight (kg) | 3200 | 7400 | 12400 |