Horizontal Automatic Scraper Discharge Centrifuge Gk 1250-N

Once Minerals Processing Coal Washing Equipment Scraper Centrifuge Coal Centrifuge Fine Slime Centrifuge was launched, it was well received by users and the market feedback was excellent, which really solved the pain points of users.

Product Description

Horizontal Automatic Scraper Discharge Centrifuge GK 1250-N

Introduction

This horizontal basket peeler centrifuge is a kind of solid liquid separation equipment with hydraulic system, It help you work in various application , like food, chemical , pharmacy. The solid mainly is the powder . like NaHCO3, kinds of starch,

It can automatic or manual finish the cyclic operation of feeding, separating, washing, discharging and screen

cleaning at full speed.

Application

The machine can also be used for heavy alkali, other materials, especially for the separation and washing dehydration of

materials with small solid particle size and difficult to separate, such as starch, calcium phosphate,etc., which can greatly

improve the operation status of separated materials such as heavy alkali and sodium bicarbonate.

Operation Model

The machine adopts PLC program control, through frequency conversion speed regulation, braking system adopts energy consumption

braking or regenerative braking, fully automatic cycle operation, free switching between manual mode and fully automatic mode.

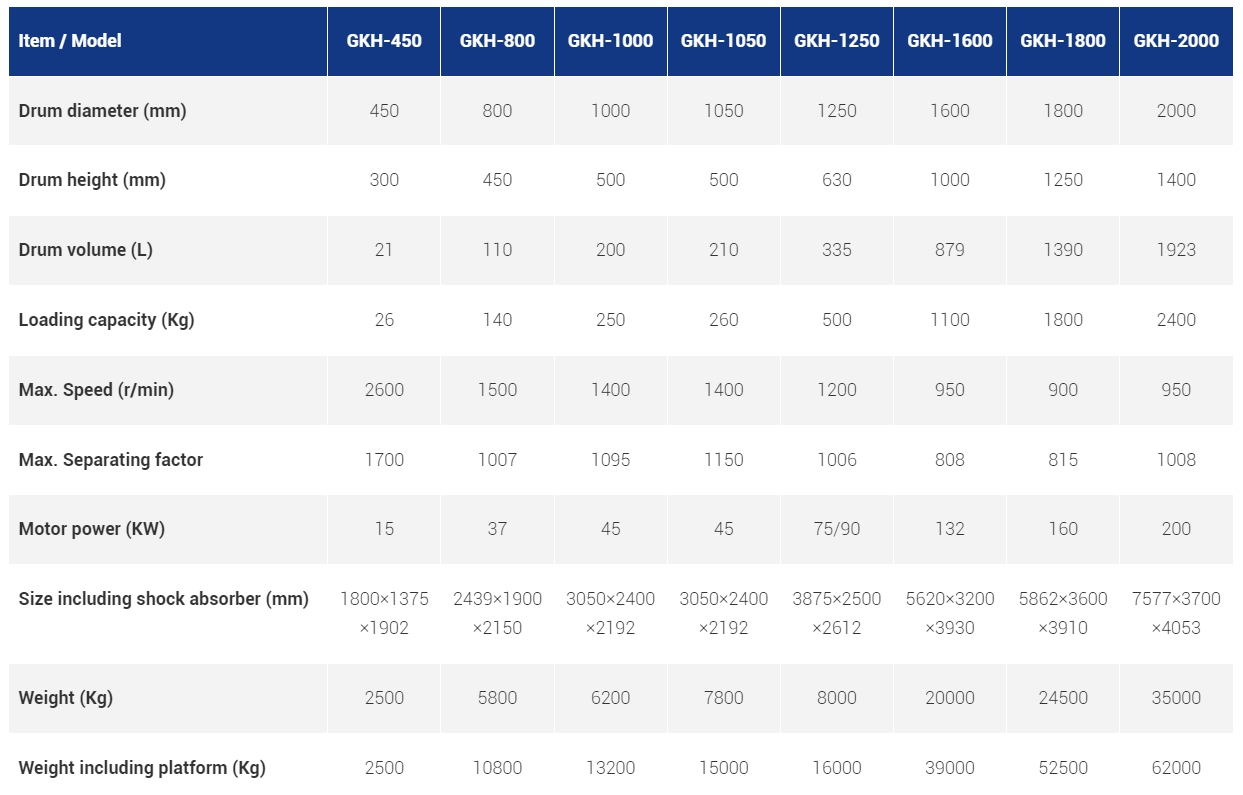

Processing parameters

Model

GK400-N, GK630-N ,GK800-N, GK1250-N, KG1600-N ,GK1800-N,GK2000-N

Characteristics

The operation of the machine is controlled by hydraulic pressure, with high automation and stable and reliable operation

The electrical system adopts advanced programmable controller, with accurate and reliable control action, small size, convenient adjustment and maintenance, high efficiency and long service life

The rubber damper is designed to greatly reduce the harm to the plant and equipment when the machine vibrates

This machine uses fluid coupling or frequency converter to control the speed transmission of the main motor, so it is not necessary to replace the friction plate as frequently as the friction centrifugal clutch

The machine is equipped with a material layer controller, and the user can adjust and control the thickness of separated materials in the drum according to the use requirements

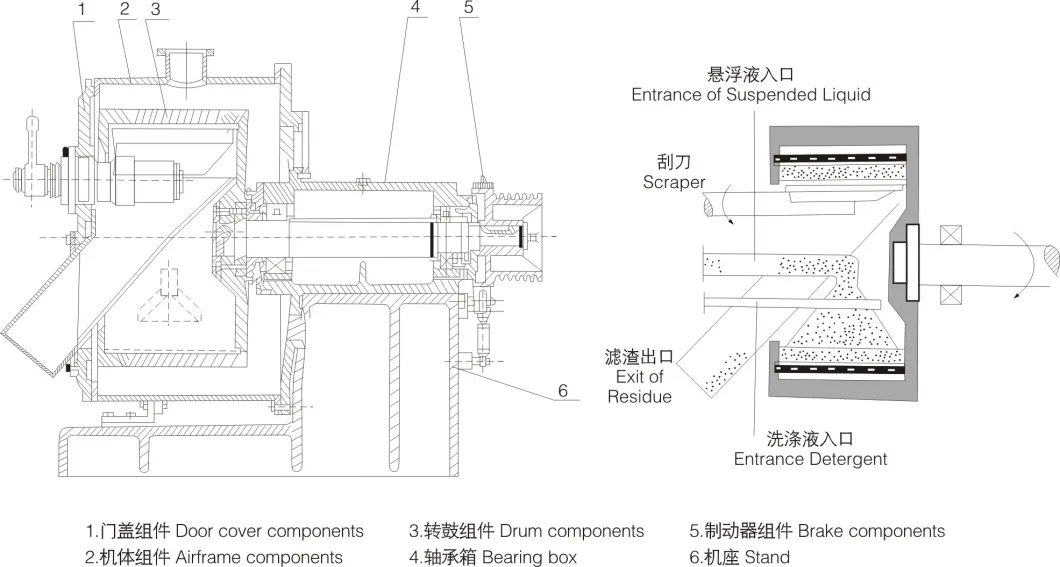

Machine structure

Special tips:

1. The technical parameters shall be subject to the product specification.

2. During the inquiry, the customer shall inform the material characteristic parameters and working conditions in detail.

3. According to the special needs of customers, we can adopt personalized design and manufacturing:

a. Material: the material of the material contact part can be ordinary stainless steel, special stainless steel or titanium alloy.

b.Motor type: ordinary or explosion-proof single speed motor can be used.

c. Electric control mode: semi-automatic, full-automatic or PLC program control can be adopted.

d.Rotating speed of drum: it can be adjusted by frequency conversion.

e.Liquid discharge method: mother liquor and washing liquor can be discharged by mixing or separating.

f. It can be designed and manufactured according to GMP specifications.

g.Other technical requirements can be negotiated.