Shenzhou - SZ Wastewater Centrifuge for Paper & Pulp Waste Solutions Centrifuge & Separator

After years of development, we have introduced and upgraded the technologies so as to make the manufacturing process more efficient.As more and more product advantages have been gradually discovered, SZ Wastewater Centrifuge for Paper & Pulp Waste Solutions enjoys a wider range of application uses and now can be found in the field(s) of Separation Equipment.

5.0

Customization:

Customized logo (Min. Order: 1 Units),Customized packaging (Min. Order: 1 Units),Graphic customization (Min. Order: 1 Units)

shipping:

Support Sea freight · Land freight

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Combining the efforts of all our staff and keeping up with the trend, Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd has developed the version of SZ Wastewater Centrifuge for Paper & Pulp Waste Solutions . It is borne with the updated features and is expected to create values and benefits for customers. It's designed out of the needs of our customers. Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd aims to become the most influential enterprise in the world. In order to achieve this goal, we will insist on introducing high-tech talents and learning international advanced technology, and strive to improve technical strength and gain the initiative in competition.

| Place of Origin: | China | Type: | Centrifuge |

| Product Type: | Plant | Condition: | New |

| Video outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | New Product 2020 | Warranty of core components: | 1 Year |

| Core Components: | PLC, Bearing, Gearbox, Motor | Brand Name: | Shenzhou |

| Voltage: | 380V/50HZ,3Phase | Power: | Model |

| Weight: | 1050 | Dimension(L*W*H): | Model |

| Warranty: | 1 Year | Key Selling Points: | Easy to Operate |

| Applicable Industries: | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Construction works , Food & Beverage Shops, Chemical plant, pharmaceutical plant | Showroom Location: | Thailand, Sri Lanka |

| After-sales Service Provided: | Field installation, commissioning and training |

Product Description

Pulp and Paper Wastewater Treatment

The waste discharge of the paper industry has a huge pollution to the environment, especially the water environment. However, the paper industry needs to use large amounts of water to treat primary fibers such as wood or pulp. Therefore, a centrifuge device for papermaking wastewater treatment is essential for the recovery and treatment of paper wastewater.

SZ Wastewater Centrifuge for Paper & Pulp Waste Solutions

SZ industrial wastewater centrifuges provide an economical and effective solution for the solid-liquid separation and dewatering of sewage and sludge in paper mills. Especially in the recycling process of printing waste paper, the wastewater will accumulate abnormal residues, separated from the wastewater by a horizontal screw centrifuge, reducing production costs and reducing pollutant emissions. It can also reduce the emission of harmful substances as much as possible.

SZ industrial wastewater centrifuges provide an economical and effective solution for the solid-liquid separation and dewatering of sewage and sludge in paper mills. Especially in the recycling process of printing waste paper, the wastewater will accumulate abnormal residues, separated from the wastewater by a horizontal screw centrifuge, reducing production costs and reducing pollutant emissions. It can also reduce the emission of harmful substances as much as possible.

Specification

Model | Diameter(mm) | Lenght(mm) | Max speed | L/D ratio | G-force | Capacity(m3/h) | Main motor power(Kw) | Weight(kg) | Dimension(mm) |

LW250*1000 | 250 | 1000 | 5000 | 4 | 2722 | 0.5-5 | 7.5 | 950 | 2120*1250*680 |

LW300*900 | 300 | 900 | 4200 | 3 | 2964 | 1-6 | 11 | 1160 | 2150*1300*900 |

LW300*1200 | 300 | 1200 | 4000 | 4 | 2784 | 2-6 | 11 | 1350 | 2450*1300*900 |

LW355*1160 | 355 | 1160 | 3600 | 3.3 | 2576 | 2-8 | 15 | 1400 | 2470*1350*830 |

LW355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 1800 | 2750*1350*830 |

LW400*1200 | 400 | 1200 | 3200 | 3 | 2294 | 3-12 | 18.5 | 1800 | 2730*1600*1080 |

LW400*1600 | 400 | 1600 | 3000 | 4 | 2016 | 3-15 | 22 | 2000 | 3130*1600*1080 |

LW450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 2500 | 3320*1700*1130 |

LW500*2000 | 500 | 2000 | 2800 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

LW530*1855 | 530 | 1855 | 2600 | 3.5 | 2006 | 5-38 | 55 | 4680 | 3885*1350*1600 |

LW530*2120 | 530 | 2120 | 2400 | 4 | 1709 | 5-40 | 55 | 4800 | 4150*1350*1600 |

LW550*2000 | 550 | 2200 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

LW650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

LW650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490-1510*1720 |

LW720*2160 | 720 | 2160 | 2000 | 3 | 1612 | 7-80 | 120 | 6000 | 5200*1600*1800 |

LW720*2880 | 720 | 2880 | 2000 | 4 | 1306 | 7-90 | 120 | 8000 | 3100*1600*1800 |

LW800*2400 | 800 | 2400 | 1800 | 3 | 1451 | 20-100 | 150 | 12000 | 5820*2000*1300 |

LW800*3200 | 800 | 3200 | 1800 | 4 | 1451 | 20-120 | 150 | 13000 | 7100*2000*1300 |

Working Principle

Special Allocation

Following allocation can be possible to meet customer's demand

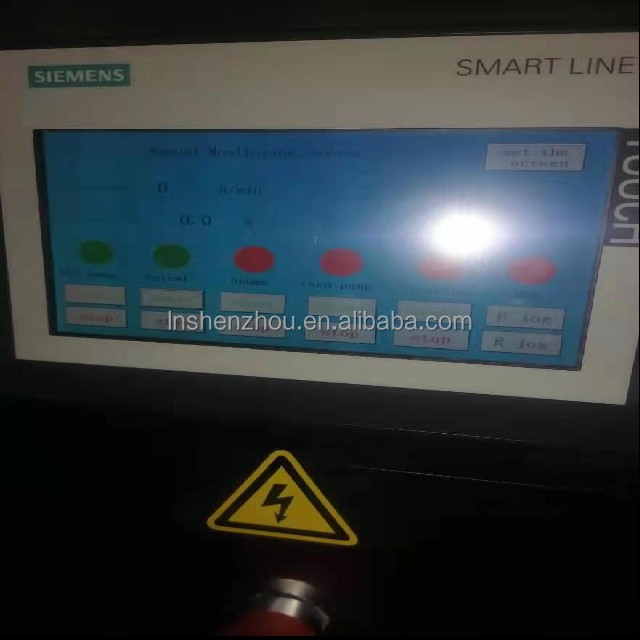

1.Frequency conversion plus PLC controlling system

2.Protection system for vibration and temperature rising

3.Feeding speed control

4.Gas-liquid separation device on liquid outlet

5.Three kinds of structure selection of cycloid gear,planetary gear and hydraulic differential. They are used to be transfered the different solid phase by pushing the torque.

Following allocation can be possible to meet customer's demand

1.Frequency conversion plus PLC controlling system

2.Protection system for vibration and temperature rising

3.Feeding speed control

4.Gas-liquid separation device on liquid outlet

5.Three kinds of structure selection of cycloid gear,planetary gear and hydraulic differential. They are used to be transfered the different solid phase by pushing the torque.

Production workshop

Screw production1

Screw production2:

.

High speed dynamic balance detection1

High speed dynamic balance detection2

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

FAQ

Q1.What's your advantage? Why we choose you?

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.

Why Choose SZ Decanter Centrifuge ?

Durable

All wear-prone areas of SZ centrifuges (separation liquid outlet, solids discharge output, screw conveyor and solids discharge section) are made of abrasion resistant material, and the rotating parts are made of high-strength centrifugally cast stainless steel. For the wear-resistant requirements of special industries, replaceable hard alloy wear-resistant pieces are added to the spiral blades.

Easy Operation

SZ decanter can run continuously and automatically. The control of the decanter centrifuge is completed through the touch screen of the control panel, and the one-key start and stop of the decanter can be realized through the control panel. The control panel interface is simple and easy to be understood, and operators can easily monitor the working status and understand the operating parameters.

Lubrication Ways

In order to meet the actual needs of different customers, SZ decanter centrifuge provide three different lubrication ways (grease pump grease lubrication, lubricating oil circulating lubrication and oil mist lubrication) for customers to choose. All lubrication systems can re-lubricate the rotor bearings during centrifuge operation.

Safety and Security

SZ decanter differential speed automatic control technology can automatically adjust the screw conveyor differential speed, to prevent overload and blockage. At the same time, SZ decanter centrifuge has vibration protection, bearing temperature protection and overload protection system. This can avoid critical operating conditions and prevent damage to centrifuge components and bearings.

Certificates

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

GET IN TOUCH WITH Us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Copyright © 2025 Shenzhou Machinery is a core subsidiary of Shenzhou Group | Sitemap