New Disc Stack Centrifuge Bowl Centrifuge Leading Centrifuge & Stack Separator Manufacturer - Shenzhou

High-end technologies are utilized to manufacture the product, making sure that the New Disc Stack Centrifuge with Self-cleaning Bowl from Chinese leading manufacturer is made to be of stable performance and high quality. It has great uses in a wide range of Separation Equipment.

Shenzhou is a leading manufacturer of disc stack centrifuges, disc bowl centrifuges, and disc stack separators. Specializing in centrifugal separation technology, Shenzhou produces high-quality equipment for various industries such as food and beverage, pharmaceuticals, chemicals, and more. Their disc stack centrifuges are known for their efficiency in separating liquids and solids, while bowl centrifuges offer reliable performance in liquid clarification and solids dewatering.

As a prominent centrifuge manufacturer, Shenzhou's disc stack separator are designed to meet the diverse needs of industrial processes, providing effective separation solutions for different applications. With a focus on innovation and quality, Shenzhou continues to develop advanced centrifuge technologies to improve process efficiency and product quality for their customers worldwide. Choose Shenzhou for reliable centrifuge solutions that lead the industry in performance and reliability.

Using highly advanced technologies and the newest methods, Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd has developed New Disc Stack Centrifuge with a Self-cleaning disc stack separator from a Chinese leading manufacturer. It is on sale starting now and we welcome your inquiry. Technological innovation is the fundamental reason for Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd to achieve sustainable development. We strictly stick to the concept of scientific design, which contributes to the unique appearance and easy-to-use performance of our Decanter centrifuge,Disc Centrifuge,Tubular Centrifuge,Plate Centrifuge. Also, we never use inferior raw materials and ensure they are all tested by our QC inspectors, thereby, guaranteeing Separation Equipment quality. We believe that our product with so many advantages can bring benefits to all customers.

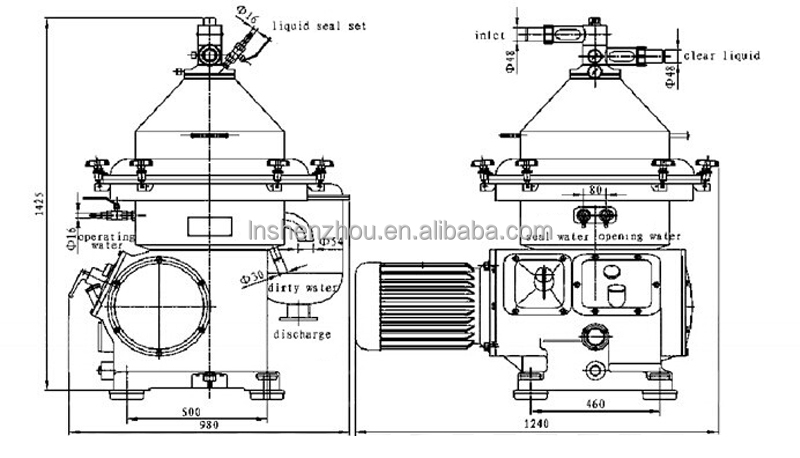

| Place of Origin: | China | Type: | Separating Plant |

| Condition: | New | Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided | Marketing Type: | Hot product |

| Warranty of core components: | 1 Year | Core Components: | Bearing, Motor |

| Brand Name: | Shenzhou | Voltage: | 220v/300v/380v/optional |

| Power: | Model | Weight: | 1500 |

| Dimension(L*W*H): | variable | Warranty: | 1 Year |

| Key Selling Points: | Easy to Operate | Applicable Industries: | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factories, Restaurant, Food Shop, Food & Beverage Shops, Advertising Company, Pharmaceutical plant, Chemical plant |

| Showroom Location: | None | Material: | Stainless Sheel |

| Feature: | High Effciency | Specification: | Centrifugal Oil Separator Machine |

| Machine name: | Disc centrifuge separator | Keyword1: | Centrifugal Filter Separator |

| Certification: | CE BV ISO |

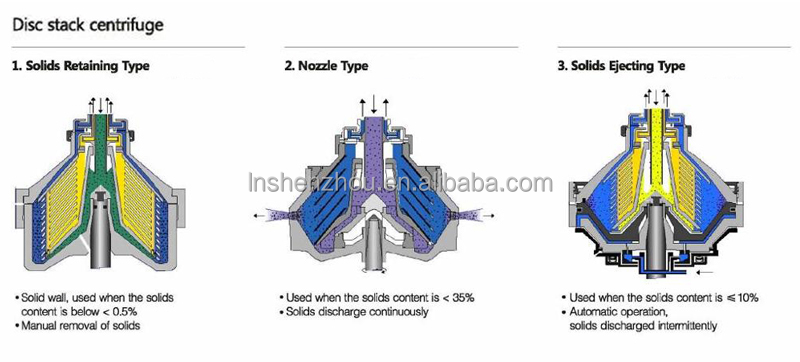

Disc separator, called dish centrifuge as well, is a kind of advanced automatic machine with high efficiency and large output, and can be applied for liquid separation in pharmaceutical, food, chemical, biological products, beverage products and other industries. With new automatic control, this advanced disc separator is superior to other separator, to achieve ideal separation effect by producing different centrifugal forces onto materials in different proportion, which make it more suitable for suspension with low solid content ,and mutually insoluble liquid with a smaller specific gravity.

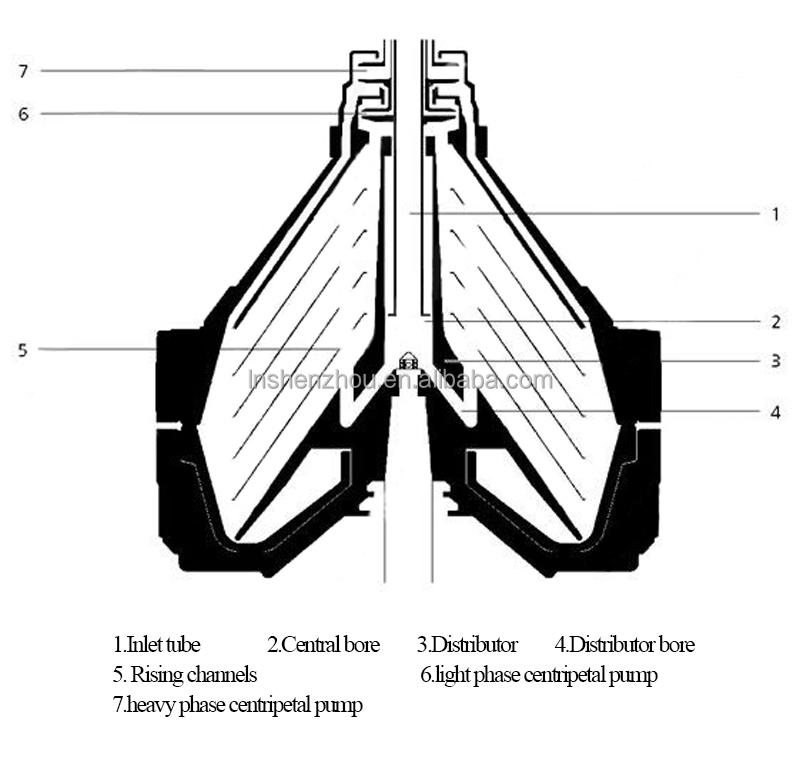

In addition, a Disc bowl separator is also be used for regenerating lubricating oils and purifying fuel used on ships or on-land electric stations. It can quickly separate water and impurities from the oil to ensure the regular operation of machines.In the centrifugal force field, different materials will be settled down at different velocity according to their respective attribute, thus separating impurities. The mixture in the high-speed rotor drum will form a cirque. From the outside to the inside, the materials lay according to their different density. For the centrifugal force is more than gravity, centrifugal separation works when gravity separation does not.

* High speed centrifugation to remove oil grease and sludge impurities

* Strong emulsification ability

* Low energy consumption,saves money

* Full automation possible with PLC automatic control panel.

* Centrifugal separation requiring no filter media.

* High reliability drive train system backed by delivery of over 1,000 units a year.

* Bowl design with superior separation performance and with good response to discharge loads.

* Pilot valve regulates total/partial discharge of solids.

* Super partial discharger (option) minimizes liquid loss and maximizes thickening of solid

* Fraction for discharge.

* Vibration-proof design realizes long working life.

Working Principle

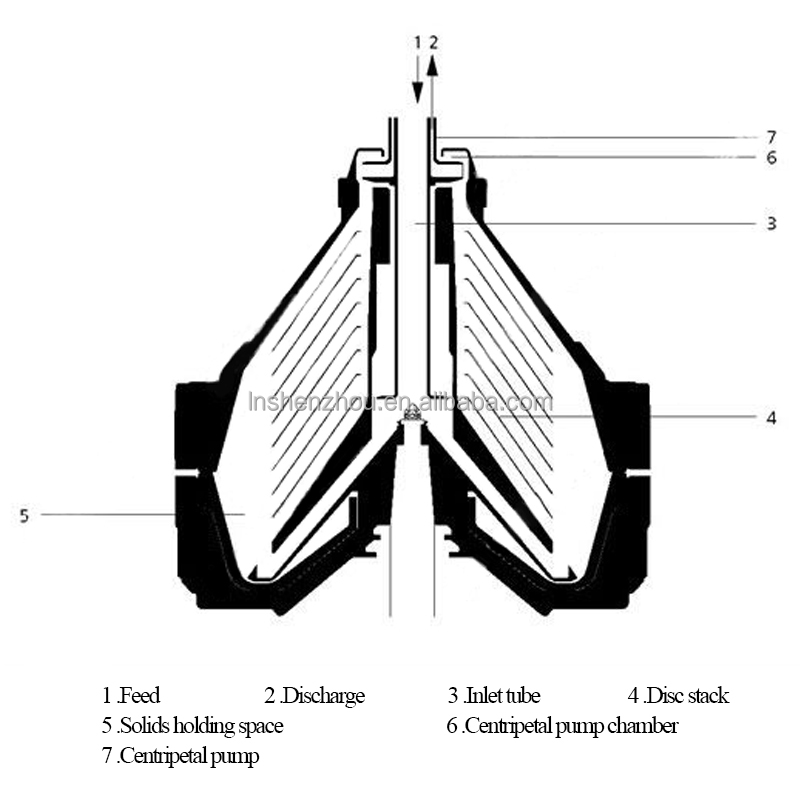

The disc separator is in vertical structure. The drum is mounted on the upper end of the vertical axis, which is driven by a motor and rotates at a high speed. There is a set of disc - shaped parts that are stacked together in the drum, with a small gap among them. When the suspension (or emulsion), which is pumped into the drum by feeding tube located in the center of the drum, pass through the gap between the discs, solid particles (or droplets) would settle down to form sediment (or liquid layer) on the disc by centrifuge force, and then the sediment slid along the surface of the disc and separated from the disc to accumulate in the largest diameter of the drum. At last, the separated liquid discharged from the outlet. The disc is utilized to shorten the settling distance of solid particles or droplets, enlarge the settlement area of the drum, and improve the production capacity of the separator. The solids accumulated in the drum are removed from the drum by manual after the machine stop, or out of the drum in the case of a dregs machine without stopping.

Besides, some nozzles is mounted around the drum to spray slurry sediment, whose number and aperture are determined on the properties of the suspension, the degree of concentration and the amount of treatment.

In order to improve the slag concentration, recovery device is configured with this disc separator to the discharged sediment for reuse. For the solid concentration of the slag can be increased by 5~20 times than that of the feeding materials.

The processing capacity of the separator is up to 30t/h, which is suitable for suspension with solid phrase in diameter of 0.1~100 microns and concentration less than 10% (maximum to 25%).

1. Oil products: the separation and clarification for vegetable oil, animal oil, fish oil, crude oil, all kinds of fuel oil,

ubricating oil,and clarification of dairy products;

2. Food: juice clarification, beer separation, broth separation and clarification for fermentation broth in fermented brewery;

3. Pharmaceuticals: extraction of vaccines, mycelium, glucose, insulin, antibiotics, vitamins;

4.Chemical industry: recovery for dry cleaning agent solvent, zinc plating solution, aluminum sulfate solution, tar water mixture, polyvinyl chloride, polypropylene, polyethylene, silver (film processing) and catalyst and magnetite .

5. Chinese medicine: the separation and clarification of plant extract.

Model | Treatment capacity (L/H) | Inlet pressure (Mpa) | Outlet pressure (Mpa) | Motor power (Kw) | Weight(Kg) | Outline dimension (mm) |

DPFX430 | 5000-20000 | 0.2 | ≤0.2 | 15 | 1250 | 1519*862*1484 |

DPFX470 | 7500-30000 | 0.2 | ≤0.2 | 30 | 1720 | 1780*1154*1710 |

DPFX550 | 25000-50000 | 0.2 | ≤0.2 | 45 | 2500 | 1860*1300*1860 |

DPFX720 | 45000-80000 | 0.2 | ≤0.2 | 75 | 3000 | 2130*1595*2242 |

wooden case

We are based in Liaoning, China, start from 1980 sell to South America(12.00%),Southeast Asia(10.00%),Northern Europe(10.00%),Southern Europe(10.00%),Domestic Market(10.00%),South Asia(8.00%),Central America(6.00%),North America(5.00%),Eastern Europe(5.00%),Africa(5.00%),Oceania(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Mid East(4.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Centrifuge,Separator,Packing machine,Drying machine,Filling & Sealing machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian