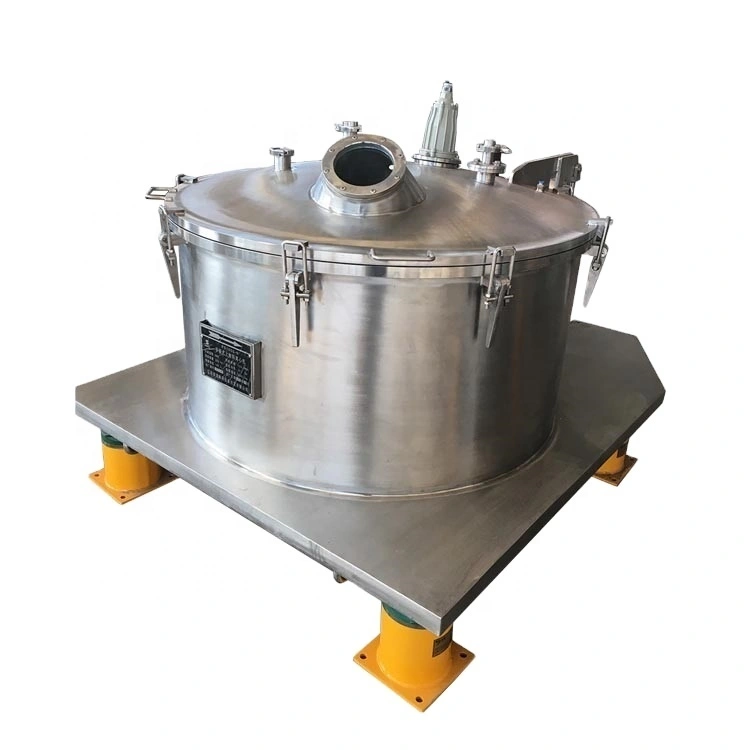

Shenzhou - Plastic psc series flat plate sedimentation explosion-proof sesame oil extraction centrifuge Centrifuge & Separator

Thanks to our committed and outstanding technical staff, our technologies have been upgraded to save more labor and cost. Its application ranges have been expanded a lot. At present, it is widely used in the field(s) of Separation Equipment.

5.0

Customization:

Customized logo (Min. Order: 1 Units),Customized packaging (Min. Order: 1 Units),Graphic customization (Min. Order: 1 Units)

shipping:

Support Sea freight · Land freight

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd has always attached great importance to the pain points of the industry. The newly launched products are specially developed to solve the pain points of the industry, which perfectly solve the pain points of the industry and are enthusiastically sought after by the market. The quality of the Plastic psc series flat plate sedimentation explosion-proof sesame oil extraction centrifuge is at the leading level in the industry and is inseparable from the hard work and innovation of outstanding technical personnel. We offer a range of design services to help you get exactly what you want.

| Place of Origin: | Liaoning,China | Type: | Centrifuge |

| Product Type: | Paint | Condition: | New |

| Video outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | New Product 2020 | Warranty of core components: | 1 Year |

| Core Components: | PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump | Brand Name: | shenzhou |

| Voltage: | 380v/220v | Power: | 7.5kw |

| Weight: | 1500 | Dimension(L*W*H): | 1400*1400*1200 |

| Warranty: | 1 Year | Key Selling Points: | Easy to Operate |

| Applicable Industries: | Food & Beverage Factory, Food Shop, Other | Showroom Location: | None |

Products Description

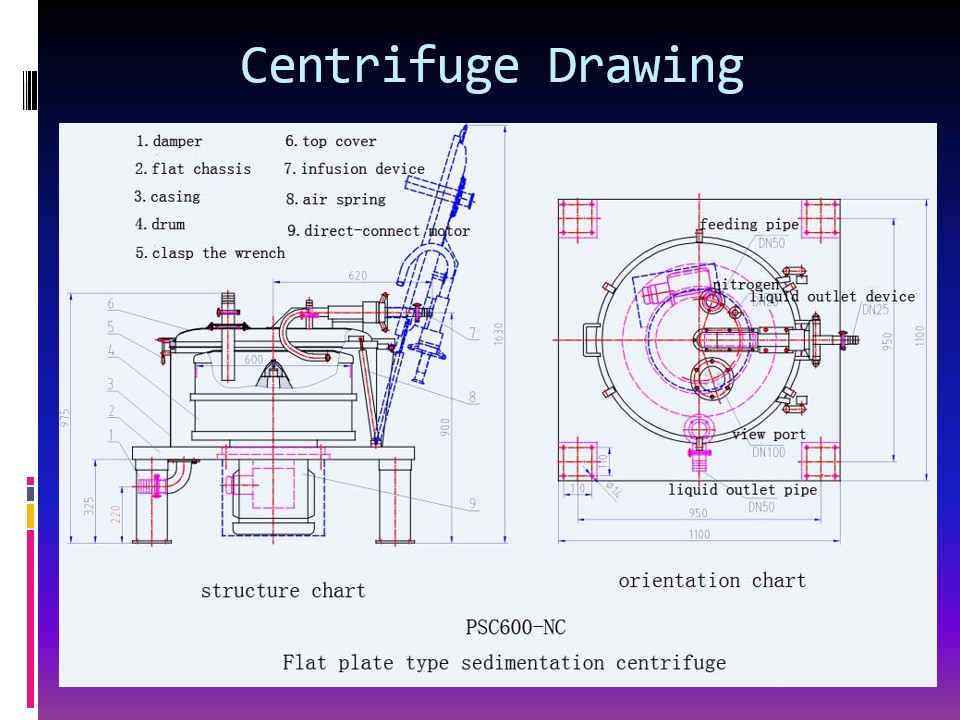

The PSC flat plate centrifuge takes the drum as the main part, and the direct-connected motor tends to rotate the drum's own axis at a high speed to form a centrifugal force field. The non-hole settling high-speed centrifuge has high rotational speed and high separation factor. The upper part is equipped with a closed cover and a skimming pipe, the feeding from the top center feeding pipe enters the central feeder under the action of gravity, the liquid phase is uniformly deposited on the inner wall of the drum through the distributor, and the centrifuge rotates at a high speed. Under the action of the centrifugal force field, the solid phase is deposited inside the drum, the liquid phase is discharged by the siphon skimming device, and the solid phase is manually discharged from the upper part after stopping.

Specification

Drum | Model | PSC450 | PSC600 | PSC800 |

Bowl Inner diameter(mm) | 450 | 600 | 800 | |

Bowl Height(mm) | 300 | 300 | 415 | |

Effective Area(m3) | 0.42 | 0.66 | 1.00 | |

liquid Blocking Plate Diameter(mm) | 320 | 420 | 560 | |

Working Volume(L) | 20 | 45 | 90 | |

Max loading Capacity(kg) | 30 | 60 | 135 | |

Rotating Speed(r/min) | 2500 | 1500 | 1500 | |

Max separating factor | 1600 | 1500 | 1000 | |

Motor | Model | YB100L-2 | YD180 | YD180 |

Motor power(kw) | 2.6 | 3.0 | 7.5 | |

Motor Rotating Speed(r/min) | 2825 | 1500 | 1500 | |

Dimension(L*W*H)(mm) | 800*800*1000 | 1100*1100*1000 | 1400*1400*1200 | |

Weight(kg) | 380 | 610 | 1300 |

Feature:

1. The structure design is reasonable, the sanitary dead angle is effectively eliminated, the structure has a smooth transition, the surface is polished, the external components, fasteners and parts in contact with materials are made of stainless steel, and the shell is flip type. the centrifuge shell and drum interlayer space can be thoroughly cleaned.

2. The machine base and flat plate structure reduces the center of gravity of the machine, occupies a small area, adopts

integral welding form between the machine base and the shell, and has high bearing strength.

3. Equipped with liquid damping fluid or rubber damping shock absorber, the vibration can be eliminated more effectively and can be installed without foundation.

4. The shell flip can be equipped with large flip or small flip according to the model, and can be covered with equipment feed pipe, washing tube, observation port, lamp port and spray system, and can also be equipped with nitrogen protection device to ensure that the chamber of the centrifuge is isolated from the external air.

5. The direct connection special motor eliminates the dust that may be brought by the belt drive, the frequency converter starts smoothly, the energy consumption braking, the whole machine sealing performance is good, can realize the airtight explosion-proof requirements, and can be used in toxic, flammable and explosive occasions. It can also be equipped with nitrogen protection device to ensure that the chamber of the centrifuge is isolated from the external air.

2. The machine base and flat plate structure reduces the center of gravity of the machine, occupies a small area, adopts

integral welding form between the machine base and the shell, and has high bearing strength.

3. Equipped with liquid damping fluid or rubber damping shock absorber, the vibration can be eliminated more effectively and can be installed without foundation.

4. The shell flip can be equipped with large flip or small flip according to the model, and can be covered with equipment feed pipe, washing tube, observation port, lamp port and spray system, and can also be equipped with nitrogen protection device to ensure that the chamber of the centrifuge is isolated from the external air.

5. The direct connection special motor eliminates the dust that may be brought by the belt drive, the frequency converter starts smoothly, the energy consumption braking, the whole machine sealing performance is good, can realize the airtight explosion-proof requirements, and can be used in toxic, flammable and explosive occasions. It can also be equipped with nitrogen protection device to ensure that the chamber of the centrifuge is isolated from the external air.

Application Case

Aiming at the properties of large solid content, fine particles and difficult filtration in the feed liquid, this machine is a

kind of equipment which can be separated under the high-speed state of density difference, which can be used alone or as the pre-treatment process of the tubular separator. in comparison with the running effect of the hanging cup centrifuge, such as the same drum speed and diameter, the machine has the advantages of large handling capacity and simple operation.

kind of equipment which can be separated under the high-speed state of density difference, which can be used alone or as the pre-treatment process of the tubular separator. in comparison with the running effect of the hanging cup centrifuge, such as the same drum speed and diameter, the machine has the advantages of large handling capacity and simple operation.

Product packaging

Why Choose Us?

Our Service

1. Professional Engineer will recommend you the most suitable model according to your requirement.

2. Supply reference process flow chart .

3. Supply on-site installation and operation test

4. Integration for control system and process

5. Customized size and structure

6. 12 Months guarantee period from machine arriving date.

7. Sufficient spare parts in stock are available .

8. Technicians are available for overseas service.

9. 24 hours technical consultation .

10. The customer could get trained by our experienced technician.

2. Supply reference process flow chart .

3. Supply on-site installation and operation test

4. Integration for control system and process

5. Customized size and structure

6. 12 Months guarantee period from machine arriving date.

7. Sufficient spare parts in stock are available .

8. Technicians are available for overseas service.

9. 24 hours technical consultation .

10. The customer could get trained by our experienced technician.

FAQ

Q1.What's your advantage? Why we choose you?

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team.More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famous good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team.More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famous good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

GET IN TOUCH WITH Us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Copyright © 2025 Shenzhou Machinery is a core subsidiary of Shenzhou Group | Sitemap