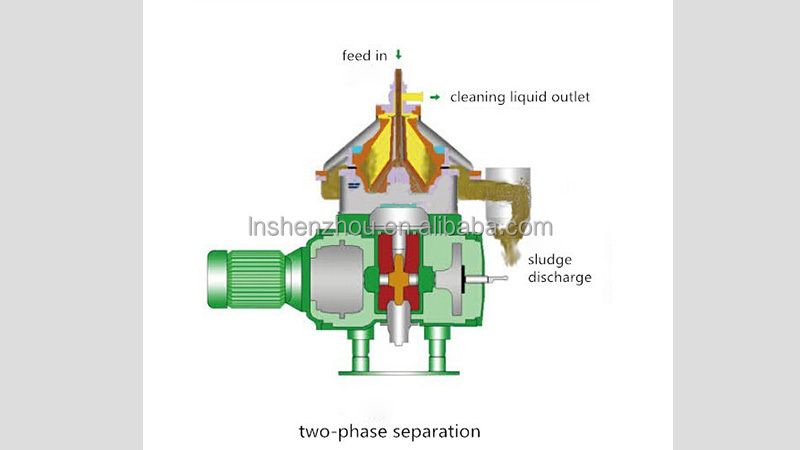

Shenzhou - 2 Phase Disc Stack Separator Centrifuge & Separator

Our months of efforts in product R&D has finally paid off. Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd has successfully transformed the innovative idea into a reality - 2 Phase Disc Stack Separator. It is the newest product series of our company now. Compared with other similar China products in the market, Decanter centrifuge,Disc Centrifuge,Tubular Centrifuge,Plate Centrifuge it can be very stable and long-lasting when applied in the field(s) of Separation Equipment. Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always stick to the core value of 'integrity and honesty' since established. We will strive forward to manufacture and provide the fine-quality products and try hard to provide the best services for our customers.

| Place of Origin: | China | Type: | Separating Plant |

| Condition: | New | Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided | Marketing Type: | Hot Product 2021 |

| Warranty of core components: | 3 years | Core Components: | PLC, Motor |

| Brand Name: | Shenzhou | Voltage: | country |

| Power: | model | Weight: | 580 |

| Dimension(L*W*H): | 600*1100*1650 | Warranty: | 3 years |

| Key Selling Points: | Easy to Operate | Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company |

| Showroom Location: | None |

solid content or big particles. Usually the particles content should be less than 3%, it’s better to be 1%. Therefore, in some application, pre-treatment will be carried out by decanter centrifuge or other separation equipment, and then clarification and separation will be carried out in the 2 phase disc stack separator. The 2 phase disc stack separator is widely used in vegetable oil clarification, biological and chemical pharmaceutical industry, dairy and beverage industry, biofuel and marine oil clarification, etc.

Model | SZLD-40 | SZLD-90 | SZLD-125 | SZLD-225 | |||

Type | Solid-Liquid Separation(Liquid Clarification) | ||||||

Bowl Diameter | 440mm | 580mm | 620mm | 800mm | |||

Sliding Piston | 380mm | 500mm | 550mm | 700mm | |||

Max Capacity | 1-2 m3/h | 5-10m3/h | 10-15 m3/h | 20-25m3/h | |||

Max Speed | 7100RPM | 6150RPM | 6000RPM | 4500RPM | |||

Max G Force | 12409G | 12273G | 12488G | 9063G | |||

Motor Power | 11KW | 18.5KW | 30KW | 45KW | |||

Feeding Pressure | 0-0.1Mpa | ||||||

Starting Time | 10-15Minutes | ||||||

Feeding Material | Solids content less 3% | ||||||

We are based in Liaoning, China, start from 2018,sell to North America(30.00%),South America(10.00%),Southeast Asia(10.00%),South Asia(7.00%),Eastern Europe(5.00%),Oceania(5.00%),Mid East(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Central America(5.00%),Northern Europe(5.00%),Southern Europe(5.00%),Africa(3.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Separator,Centrifuge,Packing & Filling,Drying,Tabling Machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian