Shenzhou - decanter centrifuge capacity 17-20 kg / h Centrifuge & Separator

Today is a great day that Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd plans to introduce our newest product to the public. It has an official name called Shenzhou and is supplied at a competitive price. By virtue of continuous technological innovation, we have mastered the core and most advanced technology in the industry, and will use advanced technology to produce decanter centrifuge capacity 17-20 kg / h, effectively solving the pain points that have always plagued the industry. In aspect of the product design, our design team always pays close attention to the customers' taste and industry trends. Thanks to this, our decanter centrifuge capacity 17-20 kg / h can fully attract people's attention with its unique appearance. Moreover, it is excellent performance, making it worth the investment.

| Place of Origin: | Liaoning, China | Type: | Centrifuge |

| Product Type: | Plant | Condition: | New |

| Video outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | New Product 2020 | Warranty of core components: | 1 Year |

| Core Components: | PLC, Bearing, Gearbox, Motor | Brand Name: | Shenzhou |

| Voltage: | 380V/50HZ,3/2Phase | Power: | 4kw |

| Weight: | 380 | Dimension(L*W*H): | 950*650*550cm |

| Warranty: | 1 Year | Key Selling Points: | Easy to Operate |

| Applicable Industries: | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Construction works , Food & Beverage Shops, Chemical plant, pharmaceutical plant | Showroom Location: | None |

| Certification: | GMP/CE |

The equipment provided by SHENZHOU GROUP is a new, advanced, mature, complete, safe and reliable equipment,and its technical performance meets the requirements in the technical accessories. The design, manufacture and quality of theLW150*650-N horizontal screw centrifuge are better than the standard of JB/T502-2004 "Screw Discharge Settling Centrifuge", and this product has passed the ISO9001-2000 quality system certification.

1. Mechanical part

2. Supply Name: LW150*650-N Horizontal Screw Discharge Decanter Centrifuge

1.1 Description of horizontal screw discharge decanter centrifuge:

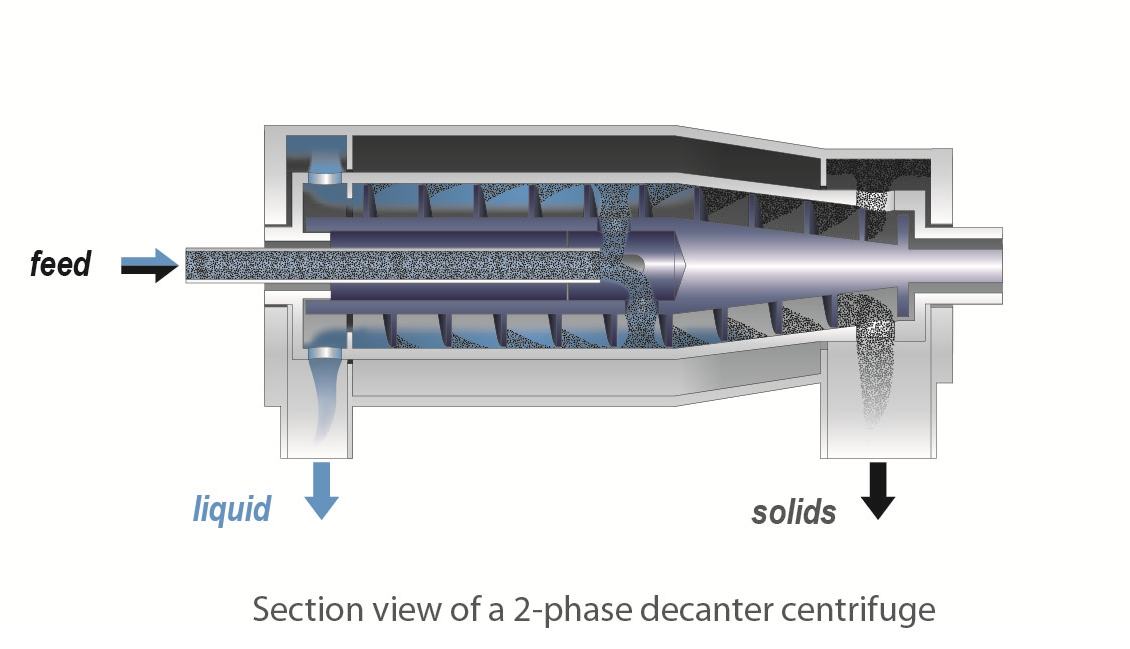

This machine is a counter-current horizontal screw discharge sedimentation centrifuge. The main machine is composed of a column-cone drum, a screw discharger, a differential system, a bearing seat, a machine base, a cover, a main and auxiliary motor and an electrical system. Its working principle is: the suspension enters the drum through the feeding pipe and the screw outlet, and under the action of the centrifugal force generated by the high-speed rotation, the solid particles with larger specific gravity are deposited on the inner wall of the drum, and move relative to the drum. The spiral blades continuously scrape the solid phase particles deposited on the inner wall of the drum and push them out of the slag discharge port, and the separated clear liquid flows out of the drum through the opening of the liquid layer regulating plate. The relative movement between the screw and the drum, that is, the differential speed is achieved through the differential, and its size is controlled by the auxiliary motor. The shell of the differential is connected with the drum, the output shaft is connected with the screw body, and the input shaft is connected with the auxiliary motor. The main motor drives the rotation of the drum and also drives the rotation of the differential housing, and the auxiliary motor controls the speed of the differential input shaft through the coupling of the coupling. The differential can transmit the torque to the screw according to a certain speed ratio, thus realizing the continuous separation process of the material by the centrifuge.

This machine adopts the most advanced special structure design in the world, and has the characteristics of better performance than ordinary centrifuges, larger processing capacity, better separation effect, energy saving, stability and reliability, and easy operation. This product has passed ISO9001: 2000 family quality system certification . The mechanical properties are higher than the standard of JB/T502-2004 "Spiral Settling Discharge Centrifuge".

1.2 Technical Specifications of Horizontal Screw Discharge Decanter Centrifuge

1.2.1 Centrifuge separation performance parameters Material properties

○Operating mode: 24 hours continuous operation.

Machine length: | 1260mm |

Machine width: | 1250mm |

Machine height: | 650mm |

Weight : | 380kg |

Diameter : | 150mm |

R/D: | 4.33 |

Design speed: | 6000r/min |

Working speed: | 5000r/min |

Separation factor | 2621 |

Differential speed: | 0.1~30r/min Stepless adjustable |

Main motor: | 4kW (380V/3/50HZ)YE2-112M-2 |

Auxiliary motor : | 1.5kW(380V/3/50HZ) YE2-90S-2 |

Motor protection level: | IP54 |

Motor insulation class: | E |

No-load vibration intensity: | ≤4.5mm/s |

The working principle of horizontal screw centrifuge is very simple. The drum and screw are supported by separate suspension, the

material is entered by the inlet tube, and the core drum is accelerated by the drum.

Separation process:

The core part consists of a cylinder and a conical rotary drum. The centrifuge forces deposit solid material on the drum wall.

Solid discharge:

The helix and the drum have the same shape and angle, and the rotating speed is slightly faster than the drum, so that the

separated solid is pushed to the narrow cone and discharged from the drum. Dehydration degree of solid depends on many factors,besides the reason of material itself, it also depends on the separation time of solid in centrifuge and the helical cone angle of conveying solid. In addition, the difference between helix and drum is also an important factor.

2. Supply reference process flow chart .

3. Supply on-site installation and operation test

4. Integration for control system and process

5. Customized size and structure

6. 12 Months guarantee period from machine arriving date.

7. Sufficient spare parts in stock are available .

8. Technicians are available for overseas service.

9. 24 hours technical consultation .

10. The customer could get trained by our experienced technician.

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.