Shenzhou - PLD Series Bag-pulling Bottom Discharge Scraper Centrifuge Centrifuge & Separator

Innovation is a factor in the long-term quality assurance of PLD Series Bag-pulling Bottom Discharge Scraper Centrifuge.The measured data indicates that products meets the market requirements.In additon,we can customize size, shape or color to suit the specific need of our customers.

5.0

Customization:

Customized logo (Min. Order: 1 Sets),Customized packaging (Min. Order: 1 Sets),Graphic customization (Min. Order: 1 Sets)

shipping:

Support Sea freight · Land freight

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Product Description

PLD Series Bag-pulling Bottom Discharge Scraper Centrifuge

The centrifuge is a type of new product with fully independent intellectual property independently developed by CONOVAL. The removal rate is higher than 99%.LDP series bag-pulling bottom discharge scraper centrifuge is a type of new product with fully independent intellectual property independently developed by us. This series centrifuge retains such primary functions offered in the LGZ series as the solid-liquid separation and scraper discharge, and adds such function as to remove the residual solid cake by pulling filter cloth with the removal rate higher than 99%.PLD series avoids crossing and mixing of different batches of separated products, and also eliminates the effects of the residual solid cake on the basket wall. It is mainly used in the solid-liquid separation process in such industries as pharmacy, food, gourmet powder and chemistry.

Operating principle:

Material to be separated enters into the basket of the centrifuge that is rotating at high speed through a feeding pipe, and under action of the centrifugal field, the material passes through the filter cloth (screen) for filtration. Then the liquid phase

discharges through the discharge pipeline, while the solid phase is retained in the basket. Feeding stops once the basket is filled with the material, then wash the solid cake, and discharge the washing liquid through filtration. The centrifuge continues to rotate to spin-dry the solid cake. After the solid cake meets the requirements for separation, the centrifuge reduces its speed, and removes the cake by means of the scraper, then discharges the cake out of the centrifuge. The centrifuge further reduces its speed so that the pneumatic pulling bag device moves reciprocally to shake off the residual solid cake, thus completely eliminating the solid cake.

Main features of LDP centrifuge:

In addition to all main features of the LGZ series centrifuge, LDP series centrifuge features as follows:

◇Removing the residual solid cake by bag-pulling method. Eliminate all solid cakes left over the process of scraper discharging through reciprocal movement of the pneumatic pulling bag device, to realize complete discharging and filtering cloth regeneration.

◇Design of removable lip ring in the basket with reliable self-locking, which is easy for changing the filter cloth.

◇External cylinder+rod drive design, reliable in work

◇Fully-enclosed discharge hopper design separating the material from the driving components of the centrifuge.

Material to be separated enters into the basket of the centrifuge that is rotating at high speed through a feeding pipe, and under action of the centrifugal field, the material passes through the filter cloth (screen) for filtration. Then the liquid phase

discharges through the discharge pipeline, while the solid phase is retained in the basket. Feeding stops once the basket is filled with the material, then wash the solid cake, and discharge the washing liquid through filtration. The centrifuge continues to rotate to spin-dry the solid cake. After the solid cake meets the requirements for separation, the centrifuge reduces its speed, and removes the cake by means of the scraper, then discharges the cake out of the centrifuge. The centrifuge further reduces its speed so that the pneumatic pulling bag device moves reciprocally to shake off the residual solid cake, thus completely eliminating the solid cake.

Main features of LDP centrifuge:

In addition to all main features of the LGZ series centrifuge, LDP series centrifuge features as follows:

◇Removing the residual solid cake by bag-pulling method. Eliminate all solid cakes left over the process of scraper discharging through reciprocal movement of the pneumatic pulling bag device, to realize complete discharging and filtering cloth regeneration.

◇Design of removable lip ring in the basket with reliable self-locking, which is easy for changing the filter cloth.

◇External cylinder+rod drive design, reliable in work

◇Fully-enclosed discharge hopper design separating the material from the driving components of the centrifuge.

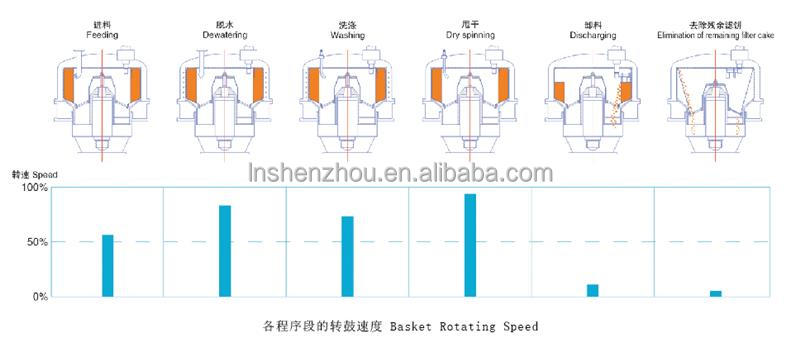

Operation procedures of LDP centrifuge:

Optional configurations:

◇ External construction: Multiple constructions including big hinged cover, fully hinged cover and flat cover

◇ Feed type: Inclined feed disk, side feed pipe, middle feed pipe and material level detection device

◇ Scraper discharge: Pneumatic, hydraulic and liquid-phase skimming disc

◇ Motor drive: Common motor, inverter-duty motor and explosion-proof motor

◇ Safety protection: Nitrogen protection (anti-explosion) system, vibration protection, temperature protection,

electric-mechanical interlocking, speed monitoring and overload protection.

◇ CIP system: Cleaning ball and spray pipe

◇ Washing mode: Atomized nozzle rinsing, feed disk washing, pulse type washing

◇ Nitrogen protection system: Automatic control device, hydraulic sealing device and gas-liquid separator.

Rapid replacement of LDP pulling bag:

Step1: open the lid (hydraulic operation)

Step2: Take down the snap ring of basket lip of filter bag and take out the steady pin of liquid interception plate and life out

the liquid interception plate.

Step3: Take down the snap ring under filter bag and take out the old filter bag.

Step4: install the new filter bag and tension the snap ring under filter bag.

Step5: install the liquid interception plate and steady pin of liquid interception plate and tension the snap ring of liquid

interception port of filter bag.

Step6: close the flip and lock it.

Step7: inspect the fitting condition of filter bag and confirm it by pulling bad.

◇ External construction: Multiple constructions including big hinged cover, fully hinged cover and flat cover

◇ Feed type: Inclined feed disk, side feed pipe, middle feed pipe and material level detection device

◇ Scraper discharge: Pneumatic, hydraulic and liquid-phase skimming disc

◇ Motor drive: Common motor, inverter-duty motor and explosion-proof motor

◇ Safety protection: Nitrogen protection (anti-explosion) system, vibration protection, temperature protection,

electric-mechanical interlocking, speed monitoring and overload protection.

◇ CIP system: Cleaning ball and spray pipe

◇ Washing mode: Atomized nozzle rinsing, feed disk washing, pulse type washing

◇ Nitrogen protection system: Automatic control device, hydraulic sealing device and gas-liquid separator.

Rapid replacement of LDP pulling bag:

Step1: open the lid (hydraulic operation)

Step2: Take down the snap ring of basket lip of filter bag and take out the steady pin of liquid interception plate and life out

the liquid interception plate.

Step3: Take down the snap ring under filter bag and take out the old filter bag.

Step4: install the new filter bag and tension the snap ring under filter bag.

Step5: install the liquid interception plate and steady pin of liquid interception plate and tension the snap ring of liquid

interception port of filter bag.

Step6: close the flip and lock it.

Step7: inspect the fitting condition of filter bag and confirm it by pulling bad.

Specification

Model | LDP800 | LDP1000 | LDP1250 | LDP1600 | LDP1800 |

Basket Dia (mm) | 800 | 1000 | 1250 | 1600 | 1800 |

Basket Volume (L) | 100 | 175 | 400 | 800 | 1250 |

Max. charge (kg) | 135 | 235 | 500 | 1000 | 1500 |

Rotation Rate of Basket (r/min) | 1200/1500 | 1100/1200 | 1000/1200 | 850 | 800 |

Relative Centrifuge Force | 645/1008 | 677/805 | 700/1008 | 647 | 645 |

Power of Motor (kg) | 7.5/11 | 15 | 22/30 | 37 | 55 |

Overall Dimension (mm) | 2050*1250*2000 | 2350*1450*2350 | 2550*1800*2550 | 3200*2400*3000 | 3500*2500*3300 |

Weight (kg) | 2000 | 3500 | 5000 | 10000 | 15000 |

Company Profile

Liaoyang Shenzhou Machinery Equipment Co., Ltd is a professional for supplier of pharmaceutical and chemical machine in China.We have a well-experienced team and a professional design institute,With rich experiences in pharmaceutical machinery and equipment including packing machine, centrifuge, falling film evaporator, distillation,mixer, tablet press machine, suppository production line,dryer,capsule filling machine ,capsule and so on.Our products are exported to many countries and areas, such as the USA, Korea, India, Indonesia,Thailand, Vietnam,Japan, Denmark,Romania, Bulgaria,Russia,South Africa, and so onAt the same time,our product with best prices and good quality,welcome to Shenzhou!

FAQ

1. who are we?

We are based in Liaoning, China, start from 2018,sell to South America(12.00%),Southeast Asia(10.00%),Northern Europe(10.00%),Southern Europe(10.00%),Domestic Market(10.00%),South Asia(8.00%),Central America(6.00%),North America(5.00%),Eastern Europe(5.00%),Africa(5.00%),Oceania(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Mid East(4.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Centrifuge,Separator,Packing machine,Drying machine,Filling & Sealing machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian

We are based in Liaoning, China, start from 2018,sell to South America(12.00%),Southeast Asia(10.00%),Northern Europe(10.00%),Southern Europe(10.00%),Domestic Market(10.00%),South Asia(8.00%),Central America(6.00%),North America(5.00%),Eastern Europe(5.00%),Africa(5.00%),Oceania(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Mid East(4.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Centrifuge,Separator,Packing machine,Drying machine,Filling & Sealing machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

GET IN TOUCH WITH Us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Copyright © 2025 Shenzhou Machinery is a core subsidiary of Shenzhou Group | Sitemap