Shenzhou - High Performance Tricanter Wastewater Centrifuge 3 Phase Variable Frequency Control Centrifuge & Separator

Except for the wisdom of intelligent and hard-working employees, the utilization of high-end technologies also plays an important role in the manufacturing process of the High Performance Tricanter Wastewater Centrifuge 3 Phase Variable Frequency Control.The product is geared towards the field(s) of Separation Equipment.

5.0

Customization:

Customized logo (Min. Order: 1 Units),Customized packaging (Min. Order: 1 Units),Graphic customization (Min. Order: 1 Units)

shipping:

Support Sea freight · Land freight

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd is a preferred manufacturer in the Separation Equipment industry. Innovation is at the core of the value that we deliver to our customers. It has been proved that high-end technologies can contribute to the high-efficiency manufacturing process.In the field(s) of Separation Equipment,High Performance Tricanter Wastewater Centrifuge 3 Phase Variable Frequency Control is widely accepted by users. Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd has always insisted on winning by "quality", and has won wide recognition and praise from many companies with high-quality services.

| Place of Origin: | China | Type: | Centrifuge |

| Product Type: | Plant | Condition: | New |

| Video outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | New Product 2020 | Warranty of core components: | 1 Year |

| Core Components: | PLC, Bearing, Gearbox, Motor | Brand Name: | Shenzhou |

| Voltage: | 380V/50HZ,3Phase | Power: | Model |

| Weight: | Model | Dimension(L*W*H): | Model |

| Warranty: | 1 Year | Key Selling Points: | Easy to Operate |

| Applicable Industries: | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Construction works , Food & Beverage Shops, Chemical plant, pharmaceutical plant | Showroom Location: | Thailand, Sri Lanka |

| After-sales Service Provided: | Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support | After Warranty Service: | Video technical support, Online support, Spare parts, Field maintenance and repair service |

| Local Service Location: | Thailand, Sri Lanka | Certification: | GMP/CE |

Product Description

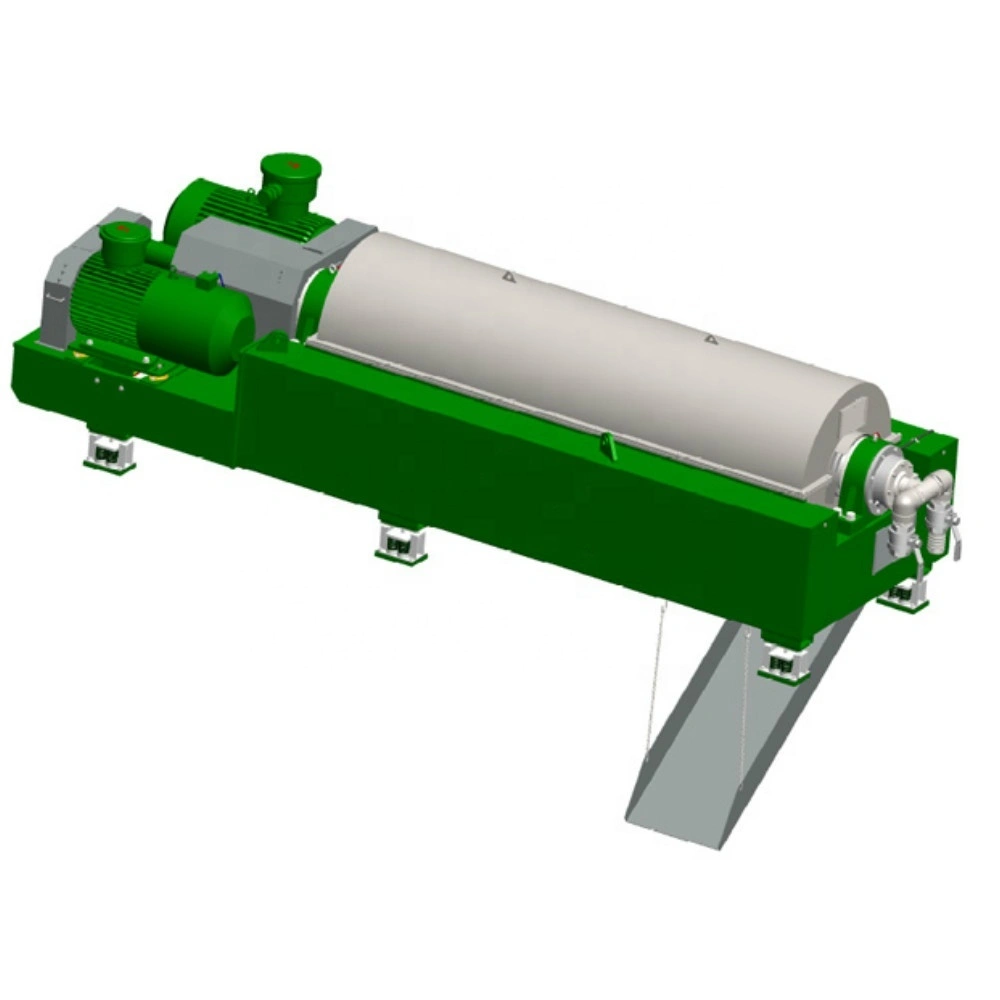

High Performance Tricanter Wastewater Centrifuge 3 Phase Variable Frequency

Modern water purification and sewage treatment processes, increasingly strict emission standards, and subsequent treatment of dewatered mud cakes, whether stacked, dried or incinerated, have set higher requirements for key equipment of excess sludge treatment.

For water purification plants and sewage treatment plants, high-performance water treatment centrifuge is an ideal solution, which is highly adaptable to sludge and has greater processing capacity at low concentration (SS 0.5). In the case of low concentration (SS 0.5%), it is not necessary to equip a concentrator to realize the dehydration function, which satisfy the requirements of the process for integrated concentration and dehydration.

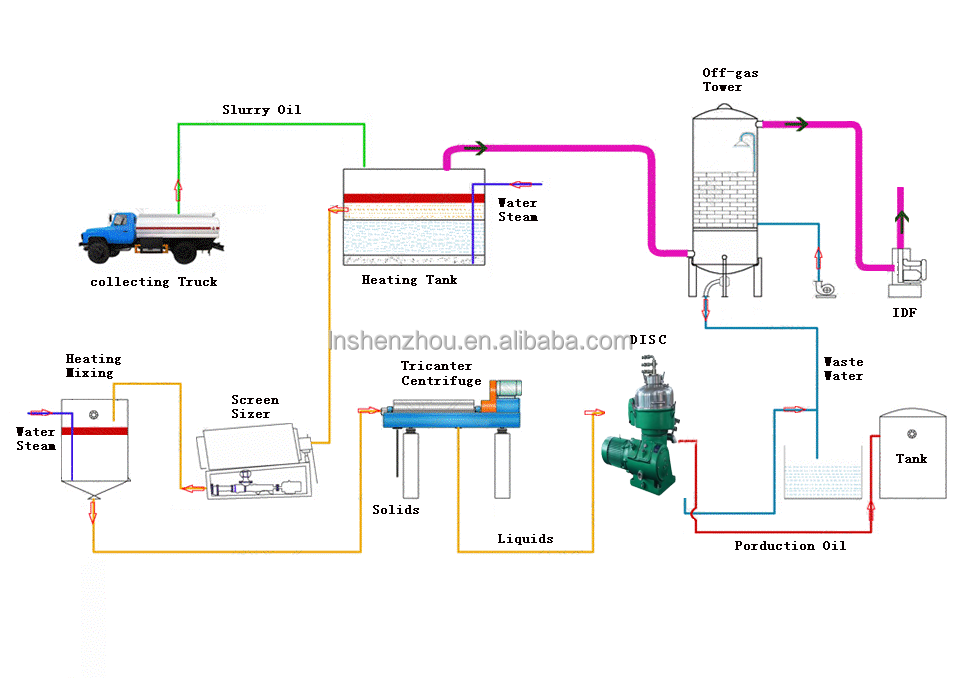

With the SHENZHOU decanter centrifuges, two liquids with different specific gravities can be individually separated from solids.

Solid-liquids are separated in the liquid phase zone and are decanted and discharged from the Solid bowl to prevent cross

contamination. There is generally is discharged under pressure and which by big gravity . The adjustment during the operation of the centrifuge ensures maximum purity of both liquid phases, thus often removing the additional downstream separation machine.

Our Centrifuge Application Scope: chemistry; pharmacy; biotechnolog; food and beverage industry; animal fat and regenerative fuels ; wastewater; oil sludge; phytoextraction, extraction,

For water purification plants and sewage treatment plants, high-performance water treatment centrifuge is an ideal solution, which is highly adaptable to sludge and has greater processing capacity at low concentration (SS 0.5). In the case of low concentration (SS 0.5%), it is not necessary to equip a concentrator to realize the dehydration function, which satisfy the requirements of the process for integrated concentration and dehydration.

With the SHENZHOU decanter centrifuges, two liquids with different specific gravities can be individually separated from solids.

Solid-liquids are separated in the liquid phase zone and are decanted and discharged from the Solid bowl to prevent cross

contamination. There is generally is discharged under pressure and which by big gravity . The adjustment during the operation of the centrifuge ensures maximum purity of both liquid phases, thus often removing the additional downstream separation machine.

Our Centrifuge Application Scope: chemistry; pharmacy; biotechnolog; food and beverage industry; animal fat and regenerative fuels ; wastewater; oil sludge; phytoextraction, extraction,

Brief Introduction

Three phase industrial centrifuge for palm oil refinery machine with palm oil disc separator for continuous separation of solids from liquids such as thickening and dewatering sludge, suspensions with granular solids, clarification of liquids, separating starch, etc. We provide a broad range of DECANTER sizes.

Main Characteristics

1.Continuous working,spiral discharging,high capacity.

2.Controlled by two motors,rovolving drum can be adjustable two stage separately.

3.Wide applicability for chemical,oil,foodstuff,pharmacy industries and green industry in which solid-liquid separation is

required.

4.Suitable for various products,capable for separating wide ranging solid phase grains(0.002-2mm),especially when separating solid phase has different size grains

Three phase industrial centrifuge for palm oil refinery machine with palm oil disc separator for continuous separation of solids from liquids such as thickening and dewatering sludge, suspensions with granular solids, clarification of liquids, separating starch, etc. We provide a broad range of DECANTER sizes.

Main Characteristics

1.Continuous working,spiral discharging,high capacity.

2.Controlled by two motors,rovolving drum can be adjustable two stage separately.

3.Wide applicability for chemical,oil,foodstuff,pharmacy industries and green industry in which solid-liquid separation is

required.

4.Suitable for various products,capable for separating wide ranging solid phase grains(0.002-2mm),especially when separating solid phase has different size grains

Material Choice

According to users' requirement,the product contact parts can be made of austenite stainless Steel(321,316L...904L,C2205),Haynes alloy titanic alloy or other anti-erosion materials

According to users' requirement,the product contact parts can be made of austenite stainless Steel(321,316L...904L,C2205),Haynes alloy titanic alloy or other anti-erosion materials

Structure Choice

1. Methods of lubrication:

A.Grease lubrication

B.Circular forced lubrication

2. Number of helical blade head is selectable within single head helix,double head helix or multiple head helix

3. Helix surface is coated with high hardness alloy

1. Methods of lubrication:

A.Grease lubrication

B.Circular forced lubrication

2. Number of helical blade head is selectable within single head helix,double head helix or multiple head helix

3. Helix surface is coated with high hardness alloy

Scope of application:

Application fields

1. Food

A flesh processing,aquatic products process and edible protein recovery;

B Extract plant protein from soybean,oily seeds and leguminous plants;

C Recovery of brewing leach liquor malt and yeast

D Treatment and recovery of wine lees liquid;

E Extract of instant coffee and tea;

F Clarification of palm oil,olive oil and seed oil;

G Extract juice from fruits ,berries and vegetables;

H Recovery of refined pectin;

I Clarification of grape juice and grape wine.

2. Environmental protection

Drilling mud ,industrial effluent ,waste water of municipal works,fertilizer,organic waste water,paint sludge,plastic

particles,gravel washing water,waste water in steel-making ,flue gas desulfurization,sewage sludge treatment of waterworks.

3. Petroleum and chemical industry

A Processing of kaolin and calcium carbonate,production of bentonite and titanium dioxide;

B Exploration of petroleum oil,natural gas,crude oil refining and related industries,additive of lube oil and waste oil recovery;

C Intermediate products and final products of organic chemistry industry;

D Thermoplastic materials,includes PVC,polypropylene,polystyrene,synthetic rubber and fiber;

E Inorganic chemical industry ,includes bleach,acid,silica products and fertilizers;

F Treatment of spent wash and molasses fermentation residues;

G Extraction of starch from wheat,corn ,cassava and potato;

H Waste liquid recovery and recycling from above industries.

Other fields

Pharmaceutical intermediates,salts and manures,etc.

A flesh processing,aquatic products process and edible protein recovery;

B Extract plant protein from soybean,oily seeds and leguminous plants;

C Recovery of brewing leach liquor malt and yeast

D Treatment and recovery of wine lees liquid;

E Extract of instant coffee and tea;

F Clarification of palm oil,olive oil and seed oil;

G Extract juice from fruits ,berries and vegetables;

H Recovery of refined pectin;

I Clarification of grape juice and grape wine.

2. Environmental protection

Drilling mud ,industrial effluent ,waste water of municipal works,fertilizer,organic waste water,paint sludge,plastic

particles,gravel washing water,waste water in steel-making ,flue gas desulfurization,sewage sludge treatment of waterworks.

3. Petroleum and chemical industry

A Processing of kaolin and calcium carbonate,production of bentonite and titanium dioxide;

B Exploration of petroleum oil,natural gas,crude oil refining and related industries,additive of lube oil and waste oil recovery;

C Intermediate products and final products of organic chemistry industry;

D Thermoplastic materials,includes PVC,polypropylene,polystyrene,synthetic rubber and fiber;

E Inorganic chemical industry ,includes bleach,acid,silica products and fertilizers;

F Treatment of spent wash and molasses fermentation residues;

G Extraction of starch from wheat,corn ,cassava and potato;

H Waste liquid recovery and recycling from above industries.

Other fields

Pharmaceutical intermediates,salts and manures,etc.

Specification

Model | Diameter(mm) | Lenght(mm) | Max speed | L/D ratio | G-force | Capacity(m3/h) | Main motor power(Kw) | Weight(kg) | Dimension (mm) |

LWS355*1160 | 355 | 1160 | 3600 | 3.3 | 2576 | 2-8 | 15 | 1400 | 2470*1350*830 |

LWS355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 1800 | 2750*1350*830 |

LWS450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 2500 | 3320*1700*1130 |

LWS500*2000 | 500 | 2000 | 2800 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

LWS550*2000 | 550 | 2000 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

LWS650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

LWS650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490*1510*1720 |

Working Principle

1)The machine starts and speeds up automatically.

2)When the proper working condition are met and the revolving drum reaches the feeding speed,the feeding valve opens and allows suspension which will be separated to enter into the product compartment of the spiral feeder through the feeding pipe.

3)After the preliminary speed-up,the suspension passes the outlet of compartment and into the drum.Because of centrifugal force, the suspension in the drum is quickly divided into two phases;the heavier solid phase deposits to the inner wall of the drum and driven by the differential gear which results in the non-cynchronous movement between the spiral feeder and the drum,the solid phase will be transferred into the small end for further dehydration and finally discharged through solid phase outlet.

4)The separated liquid flows out though the big end or will be driven out by centrifugal pump.

2)When the proper working condition are met and the revolving drum reaches the feeding speed,the feeding valve opens and allows suspension which will be separated to enter into the product compartment of the spiral feeder through the feeding pipe.

3)After the preliminary speed-up,the suspension passes the outlet of compartment and into the drum.Because of centrifugal force, the suspension in the drum is quickly divided into two phases;the heavier solid phase deposits to the inner wall of the drum and driven by the differential gear which results in the non-cynchronous movement between the spiral feeder and the drum,the solid phase will be transferred into the small end for further dehydration and finally discharged through solid phase outlet.

4)The separated liquid flows out though the big end or will be driven out by centrifugal pump.

Special Allocation

Following allocation can be possible to meet customer's demand

1.Frequency conversion plus PLC controlling system

2.Protection system for vibration and temperature rising

3.Feeding speed control

4.Gas-liquid separation device on liquid outlet

5.Three kinds of structure selection of cycloid gear,planetary gear and hydraulic differential. They are used to be transfered the different solid phase by pushing the torque.

Following allocation can be possible to meet customer's demand

1.Frequency conversion plus PLC controlling system

2.Protection system for vibration and temperature rising

3.Feeding speed control

4.Gas-liquid separation device on liquid outlet

5.Three kinds of structure selection of cycloid gear,planetary gear and hydraulic differential. They are used to be transfered the different solid phase by pushing the torque.

Production workshop

Screw production1

Screw production2:

.

High speed dynamic balance detection1

High speed dynamic balance detection2

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

FAQ

Q1.What's your advantage? Why we choose you?

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

GET IN TOUCH WITH Us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Copyright © 2025 Shenzhou Machinery is a core subsidiary of Shenzhou Group | Sitemap