Shenzhou - large capacity bentonite separation centrifuge Centrifuge & Separator

The adoption of the latest technology improves the quality of product.And the widespread use in Separation Equipment of large capacity bentonite separation centrifuge helps it win a lot of attention in the market.Besides It is designed to meet the different demand preferences.

5.0

Customization:

Customized logo (Min. Order: 1 Units),Customized packaging (Min. Order: 1 Units),Graphic customization (Min. Order: 1 Units)

shipping:

Support Sea freight · Land freight

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Please fill out the form below to request a quote or to request more information about us. please be as detailed as possible in your message, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

We always create a perfect quality of product at prices that meet a customer’s budget. Innovation ability is the key to the core competitiveness of products. Our large capacity bentonite separation centrifuge has been through multiple tests conducted by professional technicians, the purpose of which is to confirm its practical use. When applied in the application area(s) of Separation Equipment, the Decanter centrifuge,Disc Centrifuge,Tubular Centrifuge,Plate Centrifuge can be reliable and long-lasting, saving plenty cost for users.

| Place of Origin: | China | Type: | Centrifuge |

| Product Type: | Plant | Condition: | New |

| Video outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | New Product 2020 | Warranty of core components: | 1 Year |

| Core Components: | PLC, Bearing, Gearbox, Motor | Brand Name: | Shenzhou |

| Voltage: | 380V/50HZ,3Phase | Power: | Model |

| Weight: | 1050 | Dimension(L*W*H): | Model |

| Warranty: | 1 Year | Key Selling Points: | Easy to Operate |

| Applicable Industries: | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Construction works , Food & Beverage Shops, Chemical plant, pharmaceutical plant | Showroom Location: | Thailand, Sri Lanka |

| Material: | Stainless Steel |

Product Description

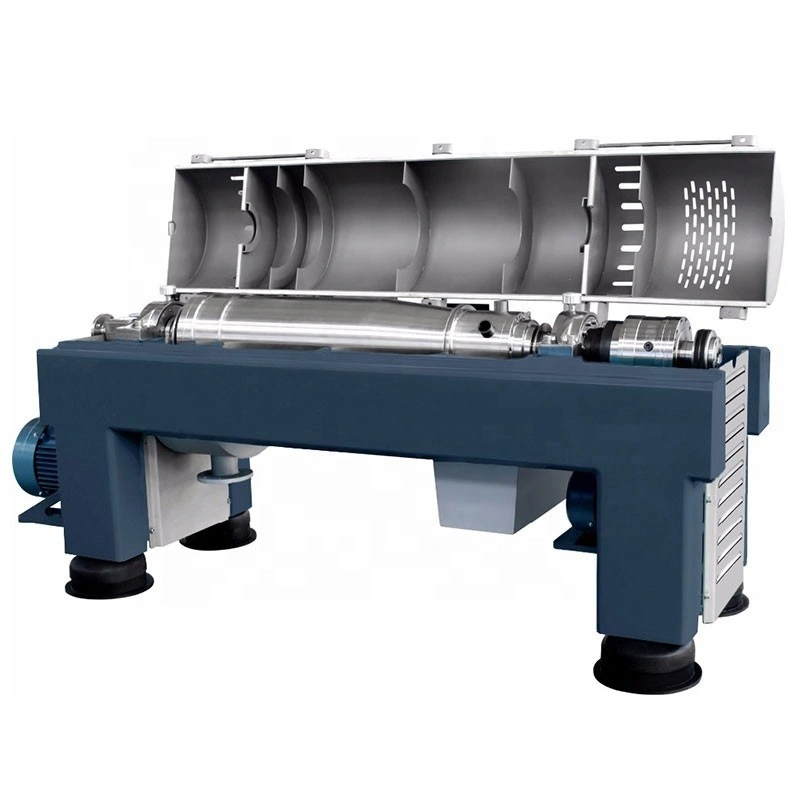

HORIZONTAL SPIRAL CENTRIFUGE FOR INDUSTRIAL SOLID-LIQUID SEPARATION

Shorted for Horizontal Spiral Sedimentation Centrifuge,Horizontal Spiral Centrifuge is a high efficient equipment to continuous finish the horizontal spiral discharging,centrifugal separation and settlement(or filtering). Due to the scientific design, Horizontal Spiral Centrifuge continuously complete feeding-separating-discharging at full speed, which is suitable for solid-liquid separation, particle size classification and liquid clarification in suspension containing solid ( 0.005 to 2mm of particle size ) with 2 ~40% of concentration. Especially, if you are looking for machine to separate suspension with the filter cloth difficult to regenerate and large range of both concentration and granularity, Horizontal Spiral Centrifuge is the most ideal machine. Featured at continuous operation, large capacity, small power consumption, compact structure and convenient maintenance, it has been successfully applied for dewatering the sludge produced in the industrial and civil sewage treatment process in chemical industry, light industry, pharmaceutical, food, environmental protection and other industries.

Shorted for Horizontal Spiral Sedimentation Centrifuge,Horizontal Spiral Centrifuge is a high efficient equipment to continuous finish the horizontal spiral discharging,centrifugal separation and settlement(or filtering). Due to the scientific design, Horizontal Spiral Centrifuge continuously complete feeding-separating-discharging at full speed, which is suitable for solid-liquid separation, particle size classification and liquid clarification in suspension containing solid ( 0.005 to 2mm of particle size ) with 2 ~40% of concentration. Especially, if you are looking for machine to separate suspension with the filter cloth difficult to regenerate and large range of both concentration and granularity, Horizontal Spiral Centrifuge is the most ideal machine. Featured at continuous operation, large capacity, small power consumption, compact structure and convenient maintenance, it has been successfully applied for dewatering the sludge produced in the industrial and civil sewage treatment process in chemical industry, light industry, pharmaceutical, food, environmental protection and other industries.

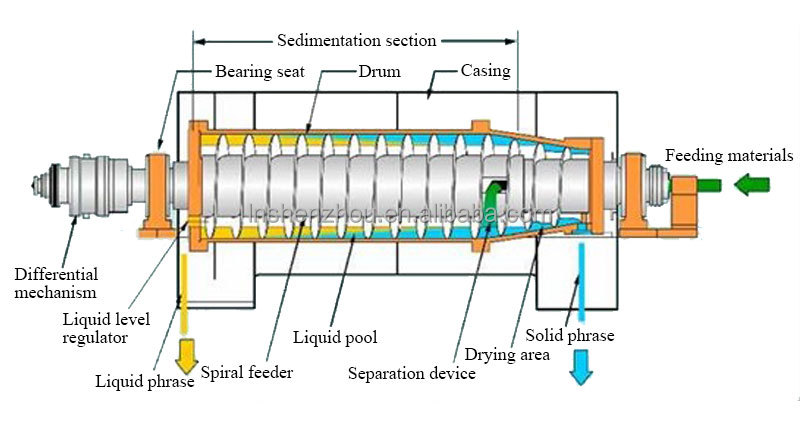

Working Principle

The concentric screw for conveying materials, is mounted inside the high-speed rotary drum without hole, and they make synclastic rotation at a certain differential speed. The material is continuously drawn into the screw inner cylinder by the feeding pipe, and they rotate at a certain differential speed which is produced by the differential. When the suspending liquid is introduced into the rotary cylinder by the central feeding tube and slide into the rotary drum after a preliminary acceleration. Under the action of the centrifugal force field, the heavier solid phase is deposited on the wall of the drum to form the sediment layer, which is pushed to the end of the rotary cylinder to be discharged from the slagging mouth, while the lighter liquid forms inner liquid ring, and continuously spilled over the drum overflow and discharged from drain outlet. In hence, separation of liquid - solid two phase of density difference can be accomplished.

Scope of application:

Application fields

1. Food

A flesh processing,aquatic products process and edible protein recovery;

B Extract plant protein from soybean,oily seeds and leguminous plants;

C Recovery of brewing leach liquor malt and yeast

D Treatment and recovery of wine lees liquid;

E Extract of instant coffee and tea;

F Clarification of palm oil,olive oil and seed oil;

G Extract juice from fruits ,berries and vegetables;

H Recovery of refined pectin;

I Clarification of grape juice and grape wine.

2. Environmental protection

Drilling mud ,industrial effluent ,waste water of municipal works,fertilizer,organic waste water,paint sludge,plastic

particles,gravel washing water,waste water in steel-making ,flue gas desulfurization,sewage sludge treatment of waterworks.

3. Petroleum and chemical industry

A Processing of kaolin and calcium carbonate,production of bentonite and titanium dioxide;

B Exploration of petroleum oil,natural gas,crude oil refining and related industries,additive of lube oil and waste oil recovery;

C Intermediate products and final products of organic chemistry industry;

D Thermoplastic materials,includes PVC,polypropylene,polystyrene,synthetic rubber and fiber;

E Inorganic chemical industry ,includes bleach,acid,silica products and fertilizers;

F Treatment of spent wash and molasses fermentation residues;

G Extraction of starch from wheat,corn ,cassava and potato;

H Waste liquid recovery and recycling from above industries.

Other fields

Pharmaceutical intermediates,salts and manures,etc.

A flesh processing,aquatic products process and edible protein recovery;

B Extract plant protein from soybean,oily seeds and leguminous plants;

C Recovery of brewing leach liquor malt and yeast

D Treatment and recovery of wine lees liquid;

E Extract of instant coffee and tea;

F Clarification of palm oil,olive oil and seed oil;

G Extract juice from fruits ,berries and vegetables;

H Recovery of refined pectin;

I Clarification of grape juice and grape wine.

2. Environmental protection

Drilling mud ,industrial effluent ,waste water of municipal works,fertilizer,organic waste water,paint sludge,plastic

particles,gravel washing water,waste water in steel-making ,flue gas desulfurization,sewage sludge treatment of waterworks.

3. Petroleum and chemical industry

A Processing of kaolin and calcium carbonate,production of bentonite and titanium dioxide;

B Exploration of petroleum oil,natural gas,crude oil refining and related industries,additive of lube oil and waste oil recovery;

C Intermediate products and final products of organic chemistry industry;

D Thermoplastic materials,includes PVC,polypropylene,polystyrene,synthetic rubber and fiber;

E Inorganic chemical industry ,includes bleach,acid,silica products and fertilizers;

F Treatment of spent wash and molasses fermentation residues;

G Extraction of starch from wheat,corn ,cassava and potato;

H Waste liquid recovery and recycling from above industries.

Other fields

Pharmaceutical intermediates,salts and manures,etc.

Specification

Model | Diameter(mm) | Lenght(mm) | Max speed | L/D ratio | G-force | Capacity(m3/h) | Main motor power(Kw) | Weight(kg) | Dimension (mm) |

LW250*1000 | 250 | 1000 | 5000 | 4 | 2722 | 0.5-5 | 7.5 | 950 | 2120*1250*680 |

LW300*900 | 300 | 900 | 4200 | 3 | 2964 | 1-6 | 11 | 1160 | 2150*1300*900 |

LW300*1200 | 300 | 1200 | 4000 | 4 | 2784 | 2-6 | 11 | 1350 | 2450*1300*900 |

LW355*1160 | 355 | 1160 | 3600 | 3.3 | 2576 | 2-8 | 15 | 1400 | 2470*1350*830 |

LW355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 1800 | 2750*1350*830 |

LW400*1200 | 400 | 1200 | 3200 | 3 | 2294 | 3-12 | 18.5 | 1800 | 2730*1600*1080 |

LW400*1600 | 400 | 1600 | 3000 | 4 | 2016 | 3-15 | 22 | 2000 | 3130*1600*1080 |

LW450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 2500 | 3320*1700*1130 |

LW500*2000 | 500 | 2000 | 2800 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

LW530*1855 | 530 | 1855 | 2600 | 3.5 | 2006 | 5-38 | 55 | 4680 | 3885*1350*1600 |

LW530*2120 | 530 | 2120 | 2400 | 4 | 1709 | 5-40 | 55 | 4800 | 4150*1350*1600 |

LW550*2000 | 550 | 2000 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

LW650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

LW650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490*1510*1720 |

LW720*2160 | 720 | 2160 | 2000 | 3 | 1612 | 7-80 | 120 | 6000 | 5200*1600*1800 |

LW720*2880 | 720 | 2880 | 2000 | 4 | 1306 | 7-90 | 120 | 8000 | 3100*1600*1800 |

LW800*2400 | 800 | 2400 | 1800 | 3 | 1451 | 20-100 | 150 | 12000 | 5820*2000*1300 |

LW800*3200 | 800 | 3200 | 1800 | 4 | 1451 | 20-120 | 150 | 1300 | 7100*2000*1300 |

Main technical features

1.Excellent adaptability:

we have fully considered all kinds of special requirements of materials and craft to centrifuges, and optimized both specificity and adjustability for the main components. If users clarify the location of their installation, physical and chemical characteristics and process requirements of material, we can provide the most suitable models.

2.High automation:

The feeding, separation, unloading, and other processes are carried out in a continuous and automatic process at high speed on this machine. The programmable controller is used to realize the automatic control of centrifugal separation and flushing.

3.Stable operation:

The cycloid wheel differential or the planetary wheel differential is selectable, which has the characteristics of large torque

and wide adjustment range.

4.Strong control:

Horizontal Spiral Centrifuge adopts dual motor, double frequency conversion, energy feedback, differential speed control system, which can flexibly adjust differential speed based on the change of material, through frequency conversion and PLC control, and thus save energy.

5.Sealed operating environment:

Horizontal Spiral Centrifuge works under completely closed conditions, which ensures the production environment clean and pollution-free.

6.Complete and reliable safety protection device:

Multiple protection, such as torque protection, power control, can effectively eliminate or reduce the damage caused by sudden failure to the machine.

7.Attractive appearance:

The machine frame is welded with high quality carbon steel, and the surface is treated with special process with good appearance.

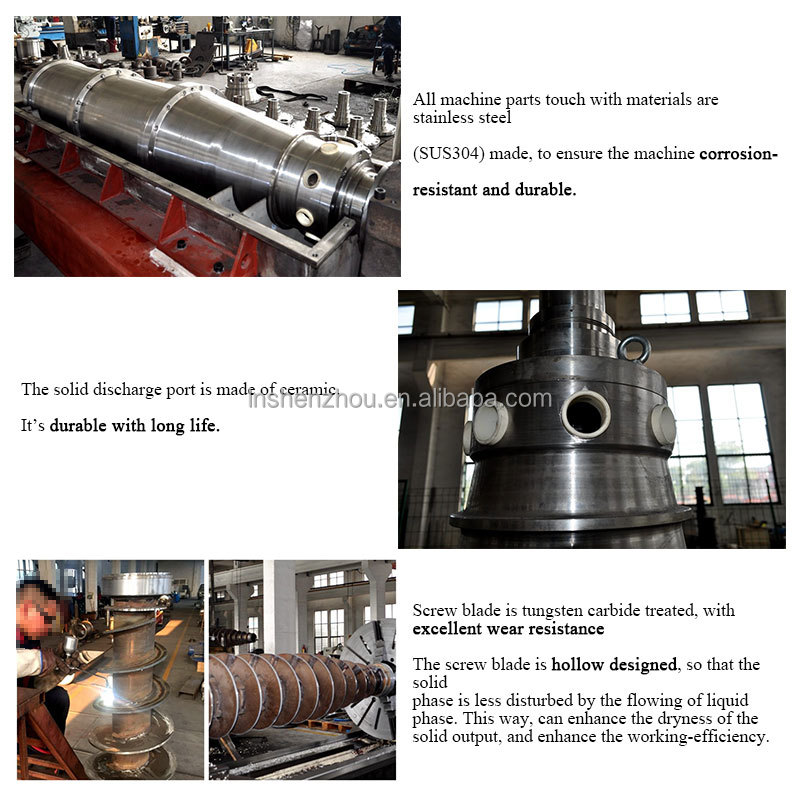

8.Good corrosion resistance:

Machine contacted with material are made of 304、316L、TA2.

9.Outstanding wear resistance:

The spiral blade is overlaid with tungsten carbide, tungsten carbide and bonded ceramic, while the discharging mouth is made of ceramic or hard alloy.

we have fully considered all kinds of special requirements of materials and craft to centrifuges, and optimized both specificity and adjustability for the main components. If users clarify the location of their installation, physical and chemical characteristics and process requirements of material, we can provide the most suitable models.

2.High automation:

The feeding, separation, unloading, and other processes are carried out in a continuous and automatic process at high speed on this machine. The programmable controller is used to realize the automatic control of centrifugal separation and flushing.

3.Stable operation:

The cycloid wheel differential or the planetary wheel differential is selectable, which has the characteristics of large torque

and wide adjustment range.

4.Strong control:

Horizontal Spiral Centrifuge adopts dual motor, double frequency conversion, energy feedback, differential speed control system, which can flexibly adjust differential speed based on the change of material, through frequency conversion and PLC control, and thus save energy.

5.Sealed operating environment:

Horizontal Spiral Centrifuge works under completely closed conditions, which ensures the production environment clean and pollution-free.

6.Complete and reliable safety protection device:

Multiple protection, such as torque protection, power control, can effectively eliminate or reduce the damage caused by sudden failure to the machine.

7.Attractive appearance:

The machine frame is welded with high quality carbon steel, and the surface is treated with special process with good appearance.

8.Good corrosion resistance:

Machine contacted with material are made of 304、316L、TA2.

9.Outstanding wear resistance:

The spiral blade is overlaid with tungsten carbide, tungsten carbide and bonded ceramic, while the discharging mouth is made of ceramic or hard alloy.

Production workshop

Screw production1

Screw production2:

.

High speed dynamic balance detection1

High speed dynamic balance detection2

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

FAQ

Q1.What's your advantage? Why we choose you?

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.

{{scoreAvg}}

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

GET IN TOUCH WITH Us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Contact Us

Contact: Megan Xu

Tel: +86 15941954210

E-mail: megan@lnszjx.com

WhatsApp: +86-15941954210

Address: No 508,Wenxi Street,Wucheng District Jinhua City China

Copyright © 2025 Shenzhou Machinery is a core subsidiary of Shenzhou Group | Sitemap