Thousands of buyers from around the world have been looking for sellers who can provide them the best quality of Separation Equipment within their cities or countries.Shenzhou is a perfect place to look for sellers and manufacturers of Centrifuge & Separator within your city or in other cities in the world. Thousands of buyers of HR Pusher Centrifuge for Fertilizer Production have been rushing towards our website because they know that they will always find the best manufacturers and sellers of the products in the world. We have always made things easy for the people who are willing to buy or sell stuff to people around the world. We strive to make the world of trade easy for both the buyers and sellers around the world. Get in touch with the sellers who meets your budget and is offering you high quality of product from our website today.

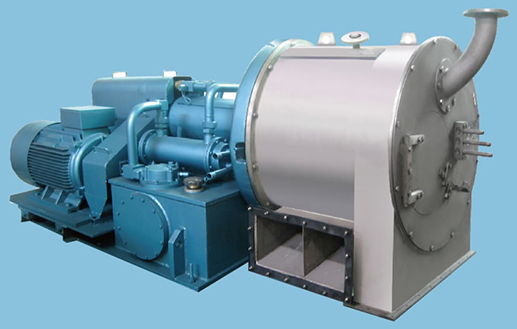

HR Series 2 stages Rock Salt Industrial Pusher Centrifuge

This two stage pusher centrifuge is used for solid washing,solid liquid separation , the solid can be the kinds of crystal/granular /fiber with particle more than 0.004 mm and the concentration > 40% . Widely for NaCI , NH4CI ,KCI ,K2SO4, NiSO4 6H2O , Ammonium chloride ,and other crystal and granular solution.

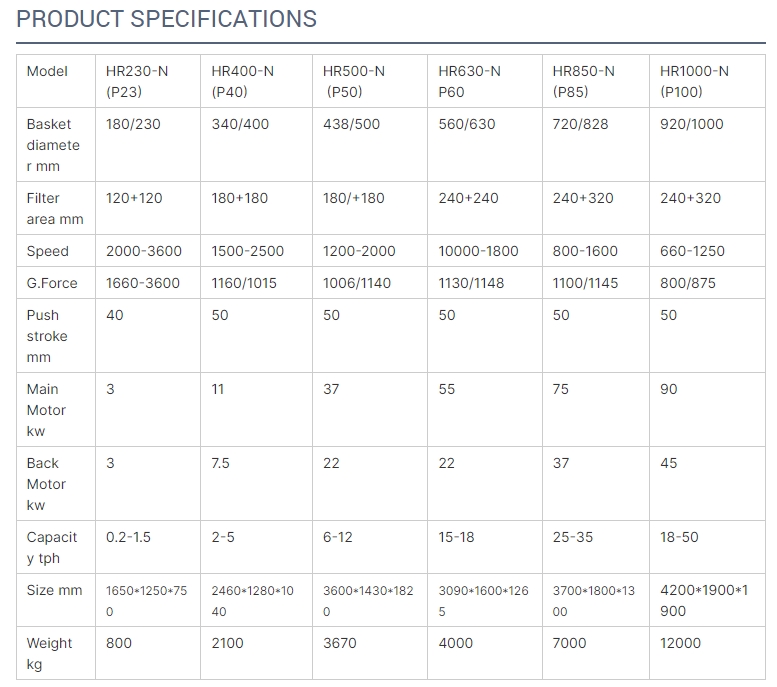

Model HR230N(P23),HR400N(P40),HR500N(P50),HR630N(P60), HR850N(P85),HR1000N(P100)

Description

Compact designComplete automatic

High capacity

Lowest moisture

Washing/dewatering separately

Remote control

Resistant to high and low temperature

Explosion proof is available.

Working Principle

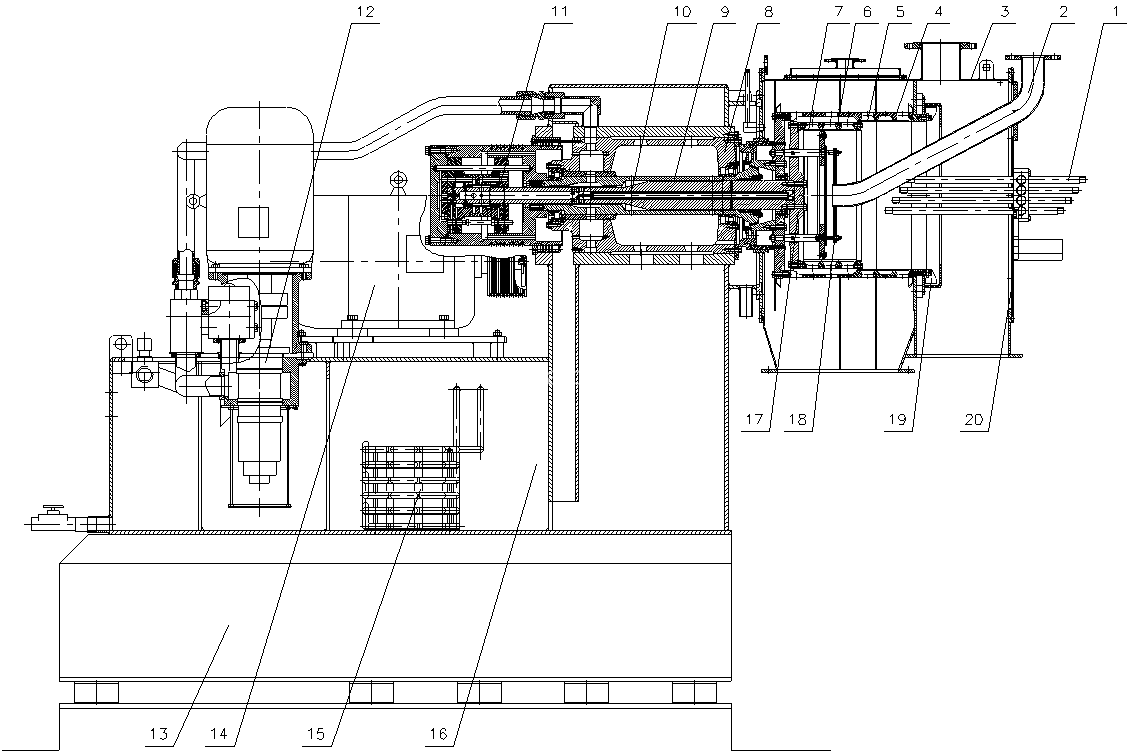

Showing above the diagram,when the basket is rotating at full speed ,the suspension liquid to be separated is fed into the feeding pipe 1 and continuously sent to the distributor 2 . Under the action of centrifugal force, the suspension liquid evenly distributed on the first stage basket screen 3, and most of liquid phase goes through out the screen mesh and the hole of basket ,while the solid phase in the form of annular filter cake stays on the screen, when the first stage basket returns and pushes the filter cake moving forward a distance along the basket axial , and when the first stage basket process , the empty surface of screen is filled with the continuous suspension liquid again and forms new filter cake. With the continuous reciprocating movement., and the filter cake pulses forward and further

drying. The filter cake goes into the secondary stage basket from the first stage basket , the filter cake is loose and

redistributed on the secondary stage basket screen and pushed out of the basket ,continuously go into the collecting tank 5 and finally the filter cake moves out of machine from the tangential discharge port by the scraper 4 installed in the secondary stage basket (if not using the scraper, the filter cake will directly drop into the machine casting.

| Structurer 1.Washing Pipe 2 Feeding Pipe 3 Machine Casing 4 Secondary Stage Basket 5 Secondary Stage Screen 6 First Stage Screen 7 First Stage Basket 8 Bearing Box 9 Hollow Shaft 10 Push Shaft 11 Composite Oil Cylinder 12 Hydraulic Device 13 Vibration Isolation Foundation 14 Main Motor 15 Cooler 16 Oil Tank 17 Push Plate 18 Distributor 19 Scraper 20 Door Cover |

| 1. The machine casing Looking in front the machine , we can see there is a circle door on the casing , we can monitor the working condition of the machine well by this door. Also there is a feed pipe and vent pipe on the top of the casing, Screw conveyor for feeding is also available. And the solid cake outlet and liquid outlet at the bottom of the casing . The material can be SS304, SS316L, Duplex2205/2507, Titanium. |  |

|  |  |

Inner of baskets There are two baskets , the main motor drives the baskets rotating ,and the oil pump motor drives the baskets pushing . and there filter screens are installed on the baskets for stopping the solid going with the liquid.. | Rear of machine There are main motor and pump motor devices. black back oil pump , kinds of instruments . | Bottom of machine There is a counterweight box at the bottom.It is used for balancing the gravity of the machine by filling the concrete .So this box makes the installation is more easier. |

Technical Parameters:

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1