Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd are confident that we will make great achievements in the future. We will unite all the elites and talents in the industry and rely on their wisdom and experience to help us upgrade our existing products and develop new products. This will make great contributions to the company development.

Structure and working principle of shenzhou two stage pusher centrifuge

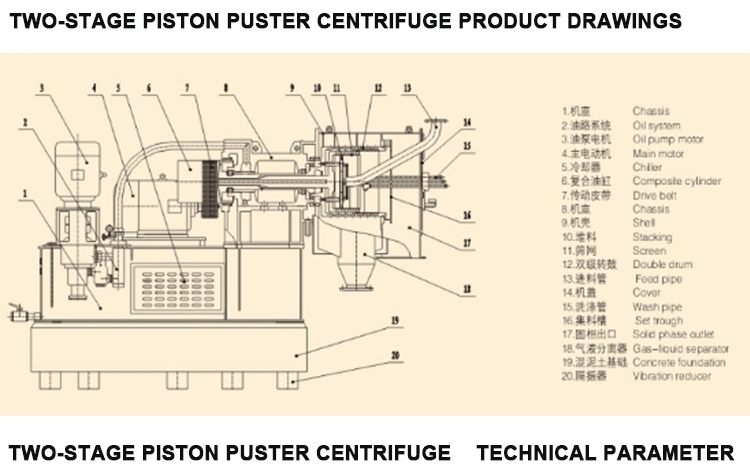

Popular Salt Refining Plant Centrifuge The horizontal two-stage pusher centrifuge pump combination, Pushing the base, bearing assembly, the drum, mesh, chassis and electrical control boxes and other component parts. Push the feeding mechanism, the drum,screen and other parts through the bearing assembly supported on the base. The base oil tanks are equipped with oil cooler.

Pump combination is also the base of support, the pump inside the oil pool, rotary connection through Triangle tape and host pulley.

The electronic control box, a separate system, installed in the appropriate position with the host.

Host at full speed, the suspension through the feed tube into the allocated disk mounted on the outer drum under the influence of centrifugal force, suspension liquid uniform distribution of the drum plate online, the liquid phase by the board net net gap and drumfilter holes and escape, while the solid phase was retention ring residues layer formed in the plate online.

Reciprocating motion of the inner drum, the residues along the drum axis goes forward, unloaded outside the drum set before the trough.

Automatic Sea Salt Separation Processing Machine 2 Stage Pusher Centrifuge

The HR series are horizontal two-stage piston-pusher filter centrifuges working on continuous operation mode. They are able to do feeding, separation, washing, discharge and other processes at full speed continually. Their features include continuous operation, steady running, high RCF, high production capacity, fine washing effect, low moisture content of cake, low solid content of mother liquor etc. They apply to separate the solid phase matter whose particle size is larger than 0.08 mm from the suspension with concentration over 40%. They are suitable to chemical industry, fertilizer, alkali, salt, and other industries, particularly suitable to sodium chloride, ammonium chloride, ammonium bicarbonate, sodium sulfate, urea and other solid-liquid separation.

Notice:

1. Please refer to the product manual for its technical parameters.

2. Please tell us the detailed feedstock characteristics, working conditions and requirements when inquiry.

3. Personalized design and manufacturing can be taken in accord with client particular needs:

* Material: The feedstock-contact parts material can be ordinary stainless steel, special stainless steel, or titanium alloy,

ect.

* Motor type: Ordinary motor or explosion-proof single-speed motor, etc.

* Liquid Discharge Method: The mother liquid and washing liquid can be discharged in mixture or discharged separately.

* Seive Gap Width Range: 0.1-0.4 mm.:0.08-0.40 mm.

* It can be designed and manufactured according to GMP specification.

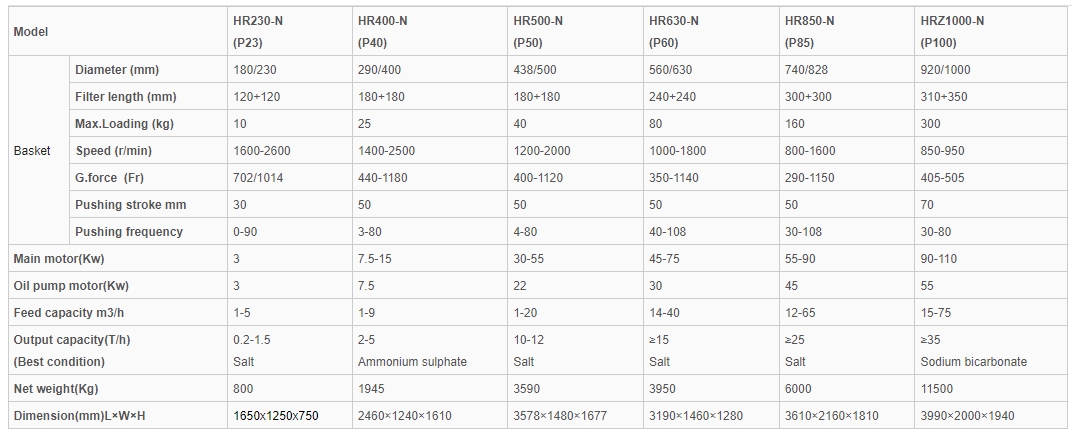

Model HR230N(P23),HR400N(P40),HR500N(P50),HR630N(P60), HR850N(P85),HR1000N(P100)

Description

Compact designComplete automatic

High capacity

Lowest moisture

Washing/dewatering separately

Remote control

Resistant to high and low temperature

Explosion proof is available.

Use and characteristics:

Popular Salt Refining Plant Centrifuge for the horizontal two-stage pusher, continuous operation of the filter centrifuge.

At full speed under all operating processes, such as feeding, separating, washing, drying and unloading. Separation of

concentrated suspensions containing particles in crystalline or short fibrous (Crystalline particle size of 0.1-10mm short fibers less than 30mm), widely used in chemical, fertilizer, salt, food, light industry, etc. industrial sectors.

The centrifuges with automatic continuous operation, continuous slagging, high production capacity, and not easy to break the grain residue can be washed and other traditional advantages, but also has high residues production, high solids recovery, low residues of moisture content, lowenergy consumption. And parts of aircraft contact with the material of stainless steel, good corrosion resistance.

Examples of application materials: sodium chloride, sodium sulfate, sodium dichromate, ammonium sulfate, boric acid, cellulose acetate, cellulose nitrate, urea, of PVC, potassium chloride, potassium sulfate, potassium carbonate.

PRODUCT CONFIGURATION

1. The casing Looking in front the machine , we can see there is a circle door on the casing , we can monitor the working condition of the machine well.

Also there is a feed pipe on the top of the casing, Screw conveyor for feeding is also available. And the solid cake outlet and

liquid outlet at the bottom of the casing .

PRODUCT CONFIGURATION

1. The casing Looking in front the machine , we can see there is a circle door on the casing , we can monitor the working condition of the machine well.

Also there is a feed pipe on the top of the casing, Screw conveyor for feeding is also available. And the solid cake outlet and

liquid outlet at the bottom of the casing .

Rear of machine:

There are main motor and pump motor devices. black back oil pump , kinds of instruments .

Bottom of machine

There is a counterweight at the bottom.It is used for balancing the gravity of the machine by filling the concrete .

technical Parameters:

FAQ

1.What's the application of centrifuge?

This machine is used to wash and dehydrate the suspension with small cystal and powder, widely used in environmental,

pharmaceutical food, chemical industry .

2.How to clean the machine?

The machine has self-cleaning function. When the processing is finished, you just put one button and the machine will do the

cleaning automatically.

3. How to choose the machine material?

For the material, we have stainless steel 304, 316 and 321 for your option. Generally SS304 is used. If there's suspension with

corrosion, then SS 321 /316 or TA is needed.

4.What's the capacity of the machine?

Firstly we have different model with different capacity for this machine.

Secondly, the capacity will be customized according to concentration of the suspension. Higher the concentration, lower the

capacity.

5. How is the processing result?

The finished cake moisture and solid lost rate is based on the material feature. And different machine just brings different

processing capacity. Also we can offer testing service to get realistic results.

Any questions, please do not hesitate to contact us anytime.

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1