Model PPS Two-stage Pusher Centrifuge is a kind of perforated basket centrifuge, both continuous and effective. The mixture to be

separated is fed through the feeding pipe and the distributor continuously and evenly into the first stage basket. Most of the mother-liquor in the feed, acted on by centrifugal force, departs through the sieves into the liquor-collecting casing where it will be discharged out of the machine. The first stage basket rotates and reciprocate, pushing the formed product cake into the second stage basket .The cake can have sufficient retardation in the centrifuge with being acted on by more centrifugal force, and therefore, the desired humidity of the cake can be guaranteed. Afterwards, the cake is continuously discharged out of the basket.

In case of high purity for the solid product, the effective washing can be carried out in the centrifuge. If necessary, the washing agent and the mother-liquor can be discharged separately.

Shenzhou - 2020 Automatic Continous Discharge Two-Stage Pusher Centrifuge for Salt Dewatering Centrifuge & Separator

he application of high-end technology perfects the function of 2020 Automatic Continous Discharge Two-Stage Pusher Centrifuge for Salt Dewatering.It can be designed to meet the needs of different customers.The product quality is accepted by customers.Therefore It can be extensively used for Separation Equipment.

5.0

Customization:

Customized logo (Min. Order: 1 Sets),Customized packaging (Min. Order: 1 Sets),Graphic customization (Min. Order: 1 Sets)

shipping:

Support Sea freight · Land freight

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Products Description

Specification

Domestic Model | P-40 | P-50 | P-60 | P-85 | P-100 | |||

International Model | HR400 | HR500 | HR600 | HR850 | HR1000 | |||

Basket | Diameter(mm) | 290/360 | 438/500 | 560/630 | 740/828 | 920/1000 | ||

Length Of Filtering Area(mm) | 180/180 | 180/180 | 240/240 | 300/300 | 310/1000 | |||

Max Solid Loading Capacity(kg) | 25 | 80 | 80 | 160 | 300 | |||

Max Speed(r/min) | 2500 | 2000 | 1900 | 1500 | 1300 | |||

Max G Force | 1015/1260 | 981/1120 | 1132/2174 | 932/1043 | 871/946 | |||

Length of Stroke(mm) | 50 | 50 | 50 | 50 | 50 | |||

Pushing Times | 30~80 | 40~80 | 40~108 | 30~108 | 30~80 | |||

Motor | Main Motor | 11~18.5KW | 37~55KW | 45~75KW | 55~90KW | 75~132KW | ||

Oil Motor | 4~7.5KW | 15~30KW | 22~37KW | 37~55KW | 45~75KW | |||

Working Oil Pressure Mpa | 2.5 | 2 | 8 | 8 | 8 | |||

Net Weight (kg) | 2480 | 4050 | 4260 | 6500 | 9000 | |||

Working Weight (kg) | 3000 | 4500 | 4800 | 7000 | 9800 | |||

Elastic Weight (kg) | 800 | 4000 | 4200 | 6000 | 8000 | |||

Feeding Capacity t/h | 0.5~9 | 1~20 | 16~40 | 12~65 | 16~75 | |||

Solid Water Content After Separation (Dehydration) | 2.5% (sea salt) | 3%(sea salt) | 4% (sea salt) | 4~5% (sea salt) | ||||

Details

Features

1.It can be operated continuously and steadily,which capacity is great.

2.Because of its high separating factor, it can be dehydrated fully in the two drums.So the filter cake will contain less moist.

3.While there is a high demand to the purity of the products the centrifuge can wash them and drain out the washing liquid and the mother liquid separately.

4.Low and even consumption of the power.

Typical separation

1.Chemical Industry: gypsum, thiamin, salt, ferric sulfate, boric acid, borax, rubber additive, dye, heavy oil and other chemical products.

2.Food industry: kitchen salt, sodium glutamate, food additive, Chemical seasonings, sugar

3.Pharmaceutical:Extraction of vitamin, biotic, traditional Chinese medicine and other various drugs

4.Mine and Metallurgy: Copper, zinc, minerals, and metal refining

5. Environmental Protection: with acid discharge, pure water sludge and sewage sludge, etc

2.Food industry: kitchen salt, sodium glutamate, food additive, Chemical seasonings, sugar

3.Pharmaceutical:Extraction of vitamin, biotic, traditional Chinese medicine and other various drugs

4.Mine and Metallurgy: Copper, zinc, minerals, and metal refining

5. Environmental Protection: with acid discharge, pure water sludge and sewage sludge, etc

Product packaging

Why Choose Us?

Our company

Liaoyang Shenzhou Machinery Equipment Co, Ltd is a professional for supplier of pharmaceutical and chemical machine in China.We have a well-experienced team and a professional design institute,With rich experiences in pharmaceutical machinery and equipment including packing machine, centrifuge, falling film evaporator, distillation,mixer, tablet press machine, suppository production line,dryer,capsule filling machine ,capsule and so on.Our products are exported to many countries and areas, such as the USA, Korea, India, Indonesia,Thailand, Vietnam,Japan, Denmark,Romania, Bulgaria,Russia,South Africa, and so on At the same time,our product with best prices and good quality,welcome to Shenzhou!

Our service

● Professional Engineer will recommend you the most suitable model according to your requirement

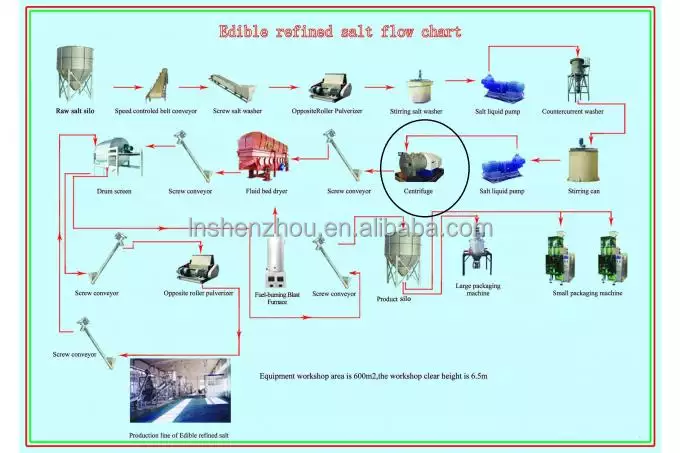

○ Supply reference process flow chart

● Supply on-site installation and operation test

○ Integration for control system and process

● Customized size and structure

○ 12 Months guarantee period from machine arriving date

● Sufficient spare parts in stock are available

○ Technicians are available for overseas service

● 24 hours technical consultation

○ The customer could get trained by our experienced technician

○ Supply reference process flow chart

● Supply on-site installation and operation test

○ Integration for control system and process

● Customized size and structure

○ 12 Months guarantee period from machine arriving date

● Sufficient spare parts in stock are available

○ Technicians are available for overseas service

● 24 hours technical consultation

○ The customer could get trained by our experienced technician

FAQ

1. who are we?

We are based in Liaoning, China, start from 2018,sell to South America(12.00%),Southeast Asia(10.00%),Northern

Europe(10.00%),Southern Europe(10.00%),Domestic Market(10.00%),South Asia(8.00%),Central America(6.00%),North

America(5.00%),Eastern Europe(5.00%),Africa(5.00%),Oceania(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Mid East(4.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Centrifuge,Separator,Packing machine,Drying machine,Filling & Sealing machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian

We are based in Liaoning, China, start from 2018,sell to South America(12.00%),Southeast Asia(10.00%),Northern

Europe(10.00%),Southern Europe(10.00%),Domestic Market(10.00%),South Asia(8.00%),Central America(6.00%),North

America(5.00%),Eastern Europe(5.00%),Africa(5.00%),Oceania(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Mid East(4.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Centrifuge,Separator,Packing machine,Drying machine,Filling & Sealing machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Leave A Message

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

no data

Related Products

no data

Copyright © 2026 Shenzhou Machinery is a core subsidiary of Shenzhou Group | Sitemap