Horizontal Peeler Discharge Centrifuges Remote Monitoring Control Security And Protection Medical Centrifuge

Advantages of siphon peeler centrifuge

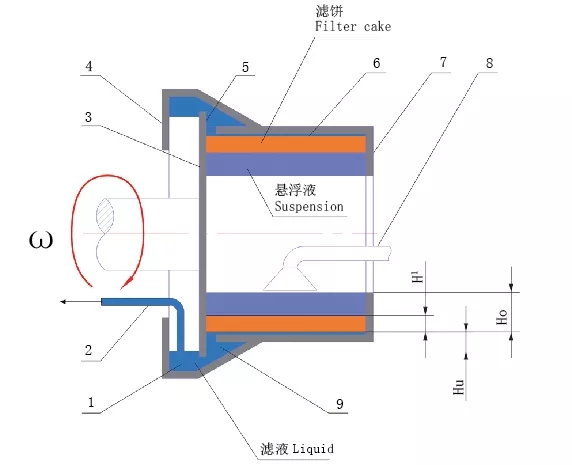

Feeding phase: As it can freely regulate the filtration rate, the filtration rate is reduced during feeding phase to prevent

uniform distribution of the cake.

Filtration phase: Siphon pipe is lower level. With the column height Hu of additional liquid, the tiltration rate is increased,

and thus the processing capacity is increased by 50% within the same time.

Washing phase: Inlet of the siphon pipe is in higher level with less filtration pushing force being generated. The washing liquid flows slowly to extend the time of the washing liquid staying in the filter cake, thus reducing loss of the washing liquid and bringing about better effects of washing.

Spin-dry phase: The inlet of the siphon pipe is at the bottom with the maximum filtration pushing torce, therefore moisture

contained in the filter cake can be removed easily, and the moisture of the filter cake is reduced.

Back-washing function: After the scraper discharges the material, the siphon can inject washing liquid into the suction chamber from the outside, and then reversely force the liquid to flow into the basket for washing. Achieve good performance of washing the filter cloth with strong ability to regenerate.

Products Features

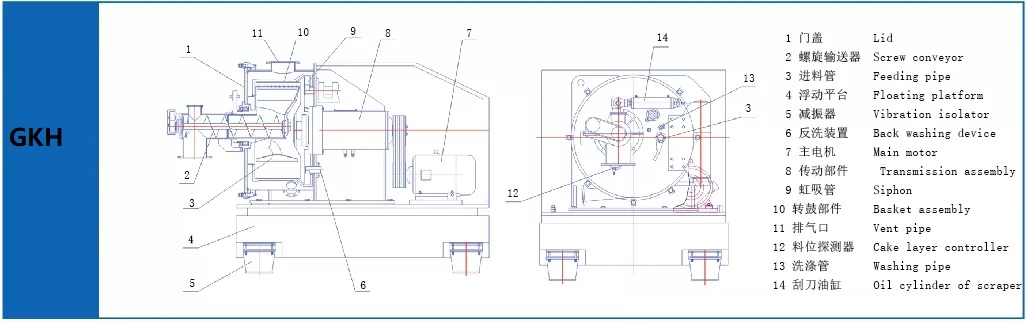

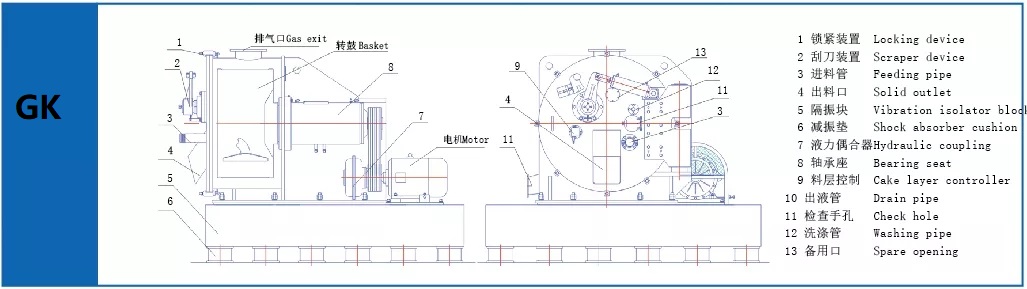

◇PLC control for long-distance monitoring; touch-screen operation and human-machine dialogue for easy maintenance and operation. ◇Action elements with automatic electric-pneumatic/hydraulic control. ◇Safety protection: includes rotation speed monitoring, over-vibration protection, cover opening protection, motor overload and overheat protection, dual control with both mechanical and electrical for scraper. ◇Welded machine case, strong and rationally design structure. ◇AII seals are made of the fluorous rubber and silicon rubber. ◇lndependent hydraulic station can be installed separately, convenient to repair. ◇Driving with hydraulic coupling (GK1250 and bigger) for stable start-up and simple control, effectively protecting the motor from overload-related damage. Optional inverter start-up for variable speed control. ◇Floating platform with rubber vibration-absorbing foundation; Liquid-damping vibration absorber is also available with excellent effects of absorbing effects, ensures stable operation of the centrifuge and reducing hazards imposed to the equipment and environment from the centrifuge vibration. ◇Two discharging modes available: chute discharging featuring simple construction; and discharging through scroll conveyor and scraper featuring high catching rate of solid cake and effectively prevent blocking. ◇GKH Peeler centrifuge offering siphon pushing force which makes filtration faster. Back washing device is available for washing and regeneration of filtration medium. Skimming device is also available to suit for separation of colloid materials containing protein.