Shenzhou - drill rig centrifuge Centrifuge & Separator

To boost Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd's sales and enhance our popularity in the global market, we strictly carry out marketing strategies, such as attending exhibitions and updating our information on social media like Facebook, to promote our products and services. Our everlasting aim is to become one of the most influential and leading enterprises in the industry.

Shenzhou has collaborated with a renowned Swiss hydraulic drive system brand to develop a fully hydraulic-driven horizontal spiral centrifuge that meets high-standard requirements from customers both domestically and internationally. The hydraulic drive system for the centrifuge drum and propeller is powered by a single motor, driving oil pumps to create two hydraulic circuits to operate the hydraulic motor and hydraulic differential. The advantages of this fully hydraulic-driven horizontal spiral centrifuge make it suitable for the separation of heavy mud in high-temperature environments."

Product Description

Shenzhou is a prominent manufacturer of oilfield Hydraulic Drive decanter centrifuges, has been dedicated to the development of fully hydraulic-driven centrifuges, ensuring they meet the highest global standards.

The hydraulic system powers both the conveyor and the bowl of a decanter centrifuge through two hydraulic oil circuits, offering distinct advantages.

This design excels in high-temperature environments, making it suitable for heavy mud applications due to its adaptable bowl and differential speed capabilities. Additionally, the compact single-skid design simplifies installation and setup.

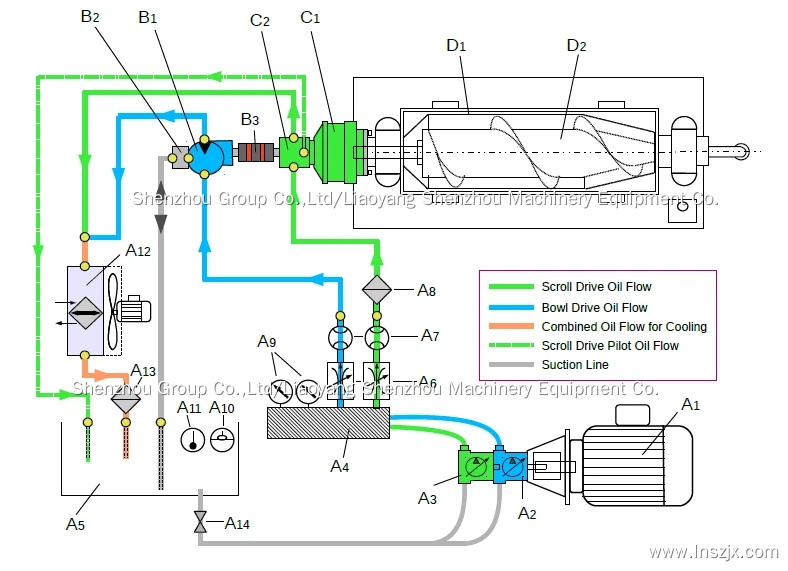

Principle Of The Hydraulic Drive System

The complete hydraulic system comprises three primary components: A - the Hydraulic Pump Unit, B - the Bowl Drive Hydraulic Motor, and C - the Scroll Drive.

Hydraulic Pump Unit A is responsible for delivering hydraulic oil to both the scroll drive C and the bowl drive B through two distinct and fully independent operating circuits.

An electric motor labeled A1 powers the combined pumps A2 and A3. Each operating circuit is equipped with its dedicated hydraulic pump and its individual control mechanisms. The pump unit includes all necessary adjustment devices, safety valves, and pressure gauges.

This system enables the manual adjustment of the bowl's rotational speed and the scroll's differential speed independently of each other, offering continuous and infinitely variable control options throughout the centrifuge's operation.

Hot Tags: hydraulic drive decanter centrifuge, China hydraulic drive decanter centrifuge manufacturers, suppliers, factory,

Techinical Parameter

Model: LWL360Bowl Size 360x1270mm

Bowl Speed 0-3400RPM (2328G)

Differential Speed 0-70RPM

Motor Power 45 KW

Driving System Switzerland Hydraulic Drive

Max Capacity 200GPM(45m3/h)

Max Torque 4163 N.M

Dimension(mm) 3000x2400x1860mm

Weight (KG) 3400KG

Model LWL360 Materail

Bowl Material : Duplex SS2304/SS2205 from centrifugal casting

Screw Material: Stainless Steel SS 304/ SS 316

Screw Protection: Tungsten Carbide Tiles

Solids Discharge: Tungsten Carbide Inserts

Bearing Brand : SKF

FHD Brand: Switzerland Hydraulic Drive

Electrical Control : PLC Smart Control

Coating Brand: Cosco & Kansai Zinc Rich Epoxy Coating

Customers:

Package show: