The 2 phase disc stack separator is used to separate the fine particles from the liquid and discharge clarified liquid. Compared with decanter centrifuge, the G force of 2 phase disc stack separator is much higher than decanter centrifuge.

The 2 phase disc stack separator is used to separate the fine particles from the liquid and discharge clarified liquid. Compared with decanter centrifuge, the G force of 2 phase disc stack separator is much higher than decanter centrifuge. The disc stack separator G force is up 12000g. Generally, the G force of the decanter centrifuge is about 3000G. The high speed and G force makes the disc stack separator to produce high clarified liquid. However, the materials separated by disc separator should not have high solid content or big particles. Usually the particles content should be less than 3%, it’s better to be 1%. Therefore, in some application, pre-treatment will be carried out by decanter centrifuge or other separation equipment, and then clarification and separation will be carried out in the 2 phase disc stack separator. The 2 phase disc stack separator is widely used in vegetable oil clarification, biological and chemical pharmaceutical industry, dairy and beverage industry, biofuel and marine oil clarification, etc.

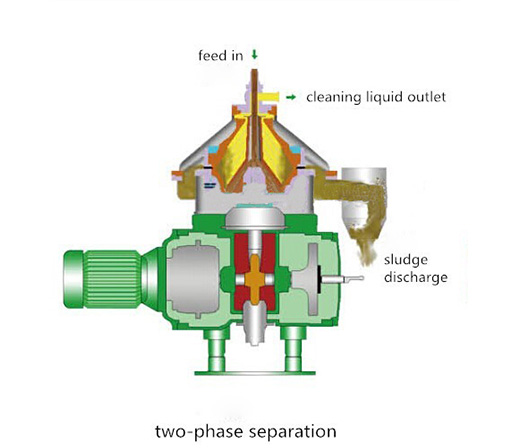

The material to be clarified enters the bowl through a feed pipe. In the distribution cabinet of the disc separator, the material is smoothly accelerated until it is synchronized with the speed of the rotary bowl. The disc stack in the rotating cylinder divides the material into many thin layers, forming a large area of clarification area. The high-speed centrifugal force makes the solid slag separated from the liquid in the disc stack deposit into the solid slag collection cavity at the edge of the bowl. The self-discharging 2 phase disc separator can be adjusted according to the material.

Vegetable oil, animal oil industry

Vegetable oils: soybean oil, rapeseed oil, sunflower oil, cottonseed oil, palm oil, corn oil, peanut oil, rice bran oil, sesame oil, safflower oil, etc.

Animal oils: lard, tallow, fish oil, pork blood, chicken blood, etc.

Dairy industry

Cold milk separation, hot milk separation, hot milk skimming, cheese concentration, goat milk skimming, colostrum extraction, and casein production.

Food and beverage industry

General fruits and vegetables: apple juice, orange juice, grape juice, lemon juice, tomato juice, carrot juice, lycopene, etc.

Vegetables: cucumber, spinach, celery, onion, garlic, lettuce, etc.

Tropical fruits: mango, pineapple, passion fruit, guava, papaya, etc.

Alcoholic drinks: wine, fruit wine, beer, medicinal liquor, etc.

Plant extraction industry

Pigment, pepper, tea, loquat leaf, honeysuckle, shuanghuanglian, ginkgo biloba, salvia, Radix Isatidis, rutin, Luo Han Guo, rhein,amygdalin, Chinese medicine extraction, etc.

Biopharmaceutical industry

Concentration of microorganisms. Separation of extracts (such as penicillin, E. coli, antibiotics, hormones, etc.). Extraction ofvitamins. Concentration and clarification of fermentation broth. Separation of animal blood.

Chemical Industry

PVC, phosphoric acid, , herbicide, insecticide, viscose, catalyst, latex (synthesis), ink and dye, lubricant additives, cellulose and derivatives, boiler ash, etc.

Mineral oil industry

Waste engine oil, cutting fluid, quenching fluid, fuel oil, lubricating oil, oil, water and solid substance mixture, etc.

Biodiesel industry

The methyl ester is washed with water, the glycerol is desalted, the fatty acid is extracted, and the methyl

ester, glycerin,catalyst, and methanol are separated.

Food waste industry

The internal organs of animal bones, vegetable stems, leaves, husks, leftovers, cooking oil, etc.

Product Features

The disc separator is a mechanical equipment that uses the principle of centrifugal sedimentation to continuously separate two liquids or solid-liquid suspensions with different densities. It has the advantages of high speed, stable operation, all closed import and export systems, low noise and good separation effect.

The parts in contact with the material of the separator are all made of stainless steel, which meets the requirements of food hygiene.

Disc separator is mainly composed of import and export device, rotating drum, vertical shaft, horizontal shaft, body, speed measuring device, brake device and electric motor. The material is discharged with a centripetal pump structure, and is discharged by a centripetal pump after separation. The output pressure is high (0-0.5MPa) and can be directly transported to downstream equipment. The drum has undergone a dynamic balance check, and a large helical gear pair is used in the power transmission to transmit power. The speed is stable, overload prevention, low vibration, safety and reliability, simple operation and convenient use. The bearings used in the equipment adopt the Swedish SKF brand to ensure the accuracy of equipment operation. After the machine is equipped with PLC electric control system, it can realize program operation.

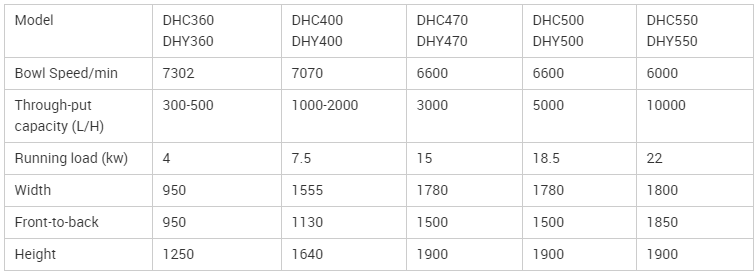

Technical Parameter:

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1