LW series of decanter centrifuge

Decanter centrifuge is a horizontal, with continuous feeding and continuous discharging. The settling speed is determined by particle size, particle shape, density difference between solids and liquids as well as their viscosity. This series of decanter centrifuge is widely applied for the solid dewatering, the liquid clarification and separation, liquid-liquid-solid separating and size-grading of various suspensions, and it is required that the particle size is 0.005 ~15mm, the consistency is 1 ~40%, and the working temperature should be not more than 100°C.

Decanters designs:

Type: 2-phase separation, 3-phase separation

Materials: use high-quality stainless steel for all product wetted areas.

Bearings: SKF brand. A special selection and arrangement of bearings provides for long life and exceptional reliability.

Wear protection: welded hard facing or spray coating,ceramic technology.

There are basically two application types in the wastewater treatment industry for the decanter centrifuge:

The first is to take liquid slurry (around 1-3% ds.) as feed to the decanter and thicken it to around 8% ds, often prior to going to a biological digester.

The second is to feed the decanter with similar slurry and dewater the solids to a dry looking solids mass prior to disposal. In the second case the solids can come from the primary clarifier or the secondary clarifier after biological treatment.

Thickening of Activated Sludge

Many effluent treatment plants use a biological treatment step to reduce the COD and BOD of a wastewater before discharging into the environment via rivers and streams. During the operation, the colonies of bacteria develop and the growing biological body produces a solid waste as it feeds on the chemicals and nutrients.

It is necessary to continuously purge the growing biological mass to control its activity and efficiency. The purge stream is usually in the form of dilute slurry, 0.5% to 3% ds, which is easier to handle if it is first thickened. Some of the thickened slurry can be returned to the biomass to maintain an optimum concentration of bacteria. The remaining waste activated sludge is for disposal.

The Reyes Centrifuge Systems range of decanter centrifuges is well designed for these duties. Controlling the decanter operating parameters can optimize the consistency of the discharged sludge.

Sludge consistency can be chosen to match the needs for disposal. Slurry for land application should be thickened to reduce the volume of water but still needs to be thin enough to be spread evenly on the land. Slurry for feed to a digester can be thicker but often still needs to be pumped. When the disposed slurry is for landfill, dewatering the feed to a stackable consistency will reduce weight, volume and disposal costs.

A simple decanter installation provides the flexibility to ‘dial in’ operating parameters to produce a choice of thickened sludge concentrations. The installation allows for the use of a polymer to help the separation but a polymer is not an essential.

The decanter will thicken an activated sludge without polymer producing solids at 6%-ds ideal for land spraying. However, the liquid centrate remains cloudy, 0.2%-ds, and can still pose a disposal problem. Many companies use a low concentration of polymer to clear up the centrate to only 200-ppm ds.

By increasing the polymer concentration and adjusting the bowl speed and conveyor speed of the decanter, the system will provide clear centrate and solids discharged at 8%-ds. Once the system is set up, the hydraulic conveyor drive automatically adjusts its speed to control the consistency of the discharged solids. These are the parameters most used to produce solids as feed to a digester.

Increasing the concentration of polymer further and again adjusting the decanter operating parameters will thicken the feed and produce stackable solids at 12%-ds. As before, once the conditions are selected, the decanter will control the solids discharge by an automatic adjustment of conveyor speed. You can clearly see the difference in the consistency of the solids in the photograph below.

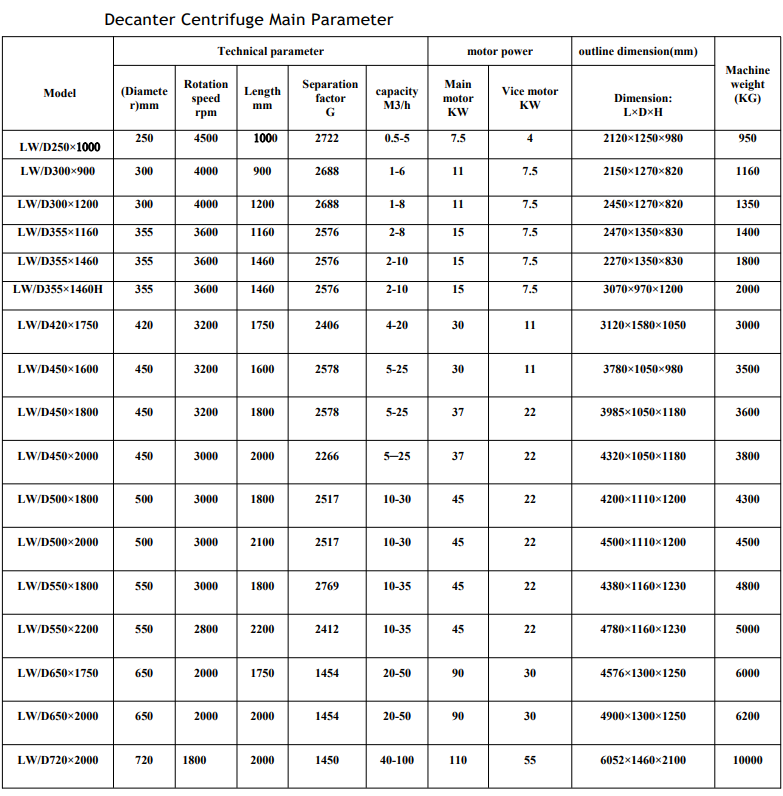

Technical paramter:

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1