Product Description

Centrifuge is the key equipment in treatment of harmful superfine solidoid in drilling liquid.(The Price is for reference. If any interest, please feel free to contact.)

The bowl and the screw make high-speed rotation with a certain differential speed between them. The feeding material will enter the bowl from the feed tube. Under the action of centrifugal force field, the liquids of high specific weight will accumlate on the inner walls of the bowl, and be discharged through the centripetal pump or overflow plate. The liquids of low specific weight will form an inner liquid ring, stick to the surfaces of heavy liquids, and be discharged from the overflow channel. Under the action of the spiral pusher, the solids in the feed will be continuously pushed to the taper end of the bowl and discharged from the residue outlet after going through the drying area.

Shenzhou waste management decanter centrifuge is the premium centrifuge with the best material configuration. It is the best option for middle term and long term investment because of it’s reliability and working life. This series of decanter centrifuge are popular for the drilling waste management,oil sludge treatment, tank cleaning waste treatment, as well as solids control, barite recovery, Low gravity and high gravity solids separation, dewatering etc.

SZ Waste Decanter Centrifuge Features:

High G Force up to max 3000. Big Volume Design.

Bowl Material Duplex Stainless Steel 2205 made from centrifugal casting.

Conveyor Wear Surface: Tungsten carbide tiles .The life is much longer than hard surface. And all tiles is interchangeable for easy maintenance.

Preasurized Explosiong Proof with PLC and HMI control for automatical operation.

All the bearings for the centrifuge are SKF brand premium bearings.

SZ Centrifuge for Drilling Waste Management

The drilling fluids recovered by the drilling cuttings dryer should go through the GLW decanter centrifuge to reduce the solids content before returning to the active mud system. The GLW decanter centrifuge can be used in WBM, SBM or OBM.

Dewatering Centrifuge for water based drilling waste

The result is a polymer enhanced flocculation of colloidal and ultra-fine drilled solids that can be efficiently removed with SZ decanter dewatering centrifuge. Without such a system, operators,would be left with the accumulation of colloidal and ultrafine drilled solids in the mud system. Ultimately leading to excessive mud densities, pipe torque/drag, mud loss, disposal fees, and overall well cost.

SZ Centrifuge for Oil Sludge Treatment

The design of the centrifuge on the telescopic skid is popular for oil sludge separation, and waste management rental business. The telescopic skid height is adjustable, It allows the liquid discharged from the centrifuge goes to storage tank by gravity without a transfer pump.

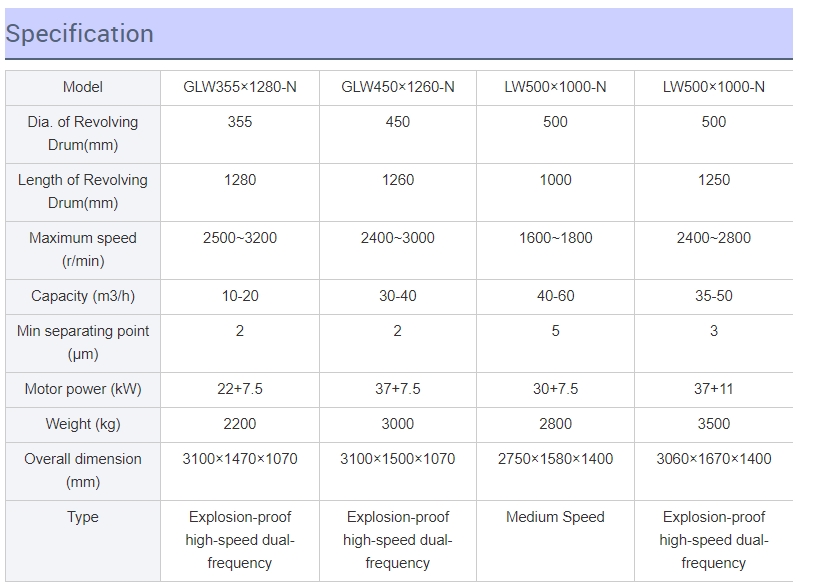

Technical Paramter:

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1