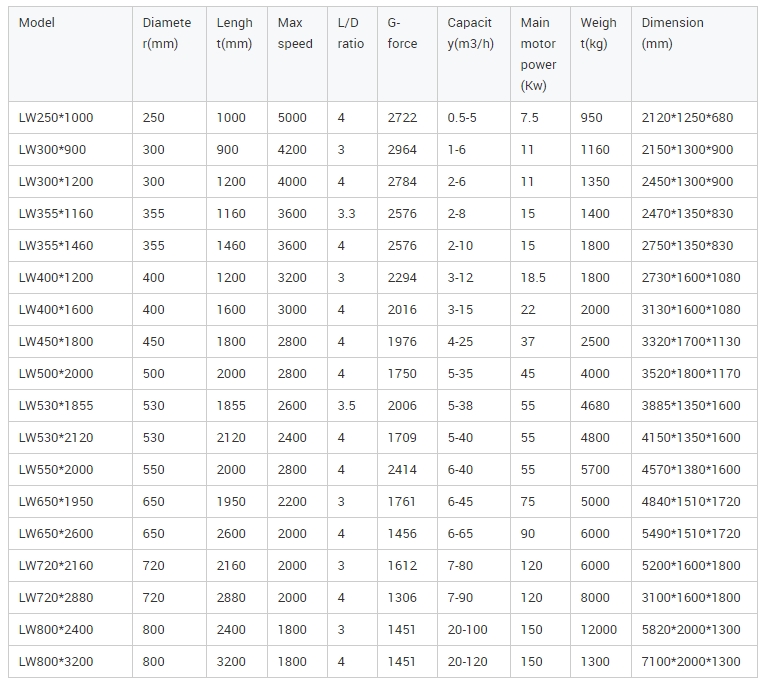

LW series of decanter centrifuge

Decanter centrifuge is a horizontal, with continuous feeding and continuous discharging. The settling speed is determined by particle size, particle shape, density difference between solids and liquids as well as their viscosity. This series of decanter centrifuge is widely applied for the solid dewatering, the liquid clarification and separation, liquid-liquid-solid separating and size-grading of various suspensions, and it is required that the particle size is 0.005 ~15mm, the consistency is 1 ~40%, and the working temperature should be not more than 100°C.

The 2-Phase decanter centrifuge is a centrifuge in which the clarified and separated oil phase is gravity discharged on the decanter centrifuge’s liquid side while the heavy liquid phase leaves the decanter together with the solids.

decanter centrifuge

The 3-Phase decanter centrifuge is a centrifuge in which two liquids of different densities are separated from each other. At the same time solids are separated and discharged.

The feedstock enters the decanter centrifuge through feed tube and flows into the centrifugation space through the distributor. The conveyor screw transports the solids to the solids discharge. The level of the liquid can be adjusted by fitting regulating rings or disks of the required inner diameter. Separation of the two liquid phases takes place in the separation zone, whereby the light phase flows towards the bowl axis, and the heavy phase towards the bowl wall.

Clarifying decanter centrifuge are designed for the continuous separation of suspensions into solids and clarified liquid, without interrupting the feed of the suspension.

Decanter centrifuge for continuous separation

The decanter centrifuge is based on the simple idea of a clarifier or settling tank, in which particles, sediment and solids gradually fall to the bottom due to the force of gravity.

decanter centrifuge

How a decanter centrifuge works

A decanter centrifuge separates solids from one or two liquid phases in one single continuous process. This is done using centrifugal forces that can be well beyond 3000 times greater than gravity.

When subject to such forces, the denser solid particles are pressed outwards against the rotating bowl wall, while the less dense liquid phase forms a concentric inner layer. Different dam plates are used to vary the depth of the liquid — the so-called pond — as required.

The sediment formed by the solid particles is continuously removed by the screw conveyor, which rotates at a different speed than the bowl. As a result, the solids are gradually “ploughed” out of the pond and up the conical “beach”.

The centrifugal force compacts the solids and expels the surplus liquid.The dried solids then discharge from the bowl. The clarified liquid phase or phases overflow the dam plates situated at the opposite end of the bowl. Baffles within the centrifuge casing direct the separated phases into the correct flow path and prevent any risk of cross-contamination.

The speed of the screw conveyor may be automatically adjusted by use of the variable frequency drive (VFD) in order to adjust to variation in the solids load.

decanter centrifuge

Decanter centrifuge for wide-ranging performance

Decanter centrifuges provide exceptional performance when separating solids from liquids, and make it possible to do so continuously,efficiently and controllably.

Decanter centrifuges are invariably the first choice to meet such separation needs by virtue of their high reliability, continuous operation, low capital cost/capacity ratio and low maintenance costs.

Decanter centrifuges are designed to handle a wide range of solid particles with diameters from 5 mm to a few microns.

Decanter centrifuges can also handle slurries with a solid content from as low as 0.1% w/w to more than 65% w/w.Decanter centrifuges can accept variations in the feed more effectively than other types of centrifuge or separation equipment.

decanter centrifuge

Screw conveyor of decanter centrifuge

The key to good decanter centrifuge performance lies in the efficient, effective scrolling of the sedimented solids. The design of the screw conveyor is therefore crucial.

Solids discharge section of decanter centrifuge

Depending on the application, the consistency of the separated solids can vary from a dry powder to a paste.The configuration of the discharge zone is therefore chosen to enable such “cakes” to exit as effectively as possible.

Liquid discharge section of decanter centrifuge

In a two-phase decanter centrifuge, the liquid level is regulated by dam plates.When operating in a three-phase decanter centrifuge, each phase discharges over a set of dam plates into separate baffled compartments in the casing.

decanter centrifuge

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1