China Shenzhou Continuous Oil Water solid separator Disc Centrifuge manufacturers - Shenzhou Machinery

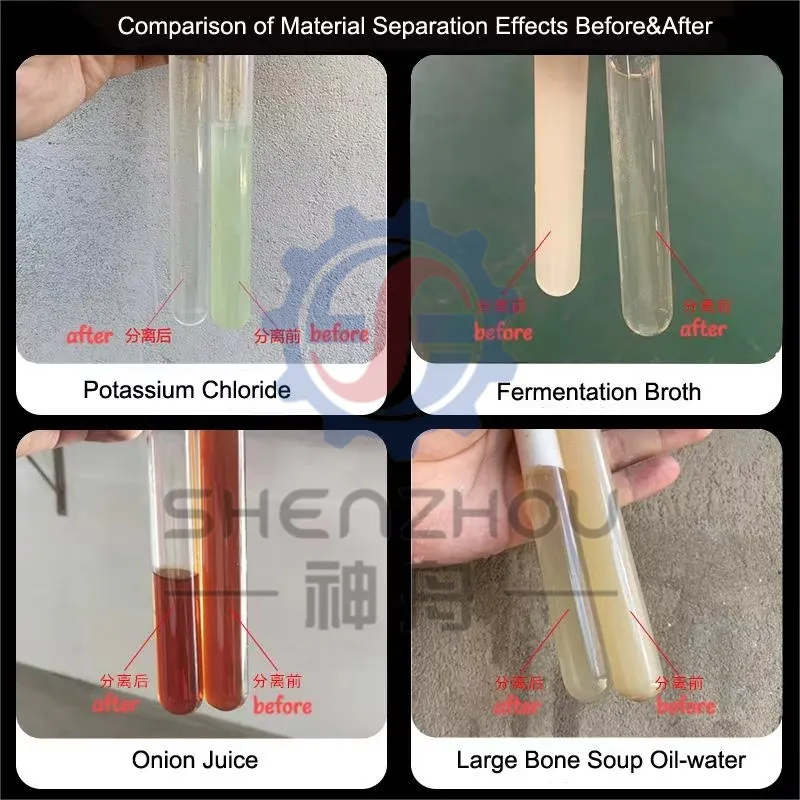

The disc separator is specially used for the two-phase and three- phase separation. The two-phase separation is to separate the suspended solid from liquid or two liquids which have the different specific gravity and are immiscible. The three-phase separation is to separate the two immiscible liquid phases and a phase of solid at the same time.

1. Liquid solid separation (i.e. separation of bottom concentration suspension), which is called clarification operation, that is two-phase separation.

2. Liquid-liquid separation (or liquid-liquid-solid) separation (i.e., the separation of emulsion) is called separation operation,that is three-phase separation.

Product Introduction

China Shenzhou Continuous Oil Water solid separator Disc Centrifuge manufacturers - Shenzhou Machinery

Shenzhou Separator has been at the forefront in the field of disc stack centrifugal separation technology for more than 50 years - which is why disc stack centrifuges from Shenzhou Separator perform this crucial separation function exceptionally well.

Today, Shenzhou Separator is the leader in mechanical separating technology in China. Shenzhou developments are used in a wide range of areas - in the beverage and dairy industries, in recovering and processing oils and fats, as well as in chemicals, pharmaceuticals, biotechnology and starch technology. Other applications include marine engineering, energy, oil fields and industry.

Centrifuge machine Standard design

The machine consists of a frame that has a horizontal drive shaft with clutch and brake, worm gear , lubricating oil bath and vertical bowl spindle in the lower part.

The bowl is mounted on top of the spindle in the lower part. The bowl is mounted on top of the spindle , inside the space formed by the upper parts of the frame , the ring solid cover, the collecting cover, and frame hood . The feed and liquid discharge system , including the paring disc pump for the heavy phase, also rests on this structure. All parts in contact with the process liquid are made of stainless steel. The bowl is of the solid-ejecting disc type with hydraulic operating system. The electric motor is of the variable frequency drive type or of controlled-torque type.

Company Advantages

We have always followed the standardization rules for a rigorous production process, saving time and cost for both parties and bringing maximum benefits to you.

18 million orders from foreign countries.

We provide CAD and 3D design sketches. We perform three phases of QC to ensure product quality.

Its thermal resistance meets the American ASTM standard.

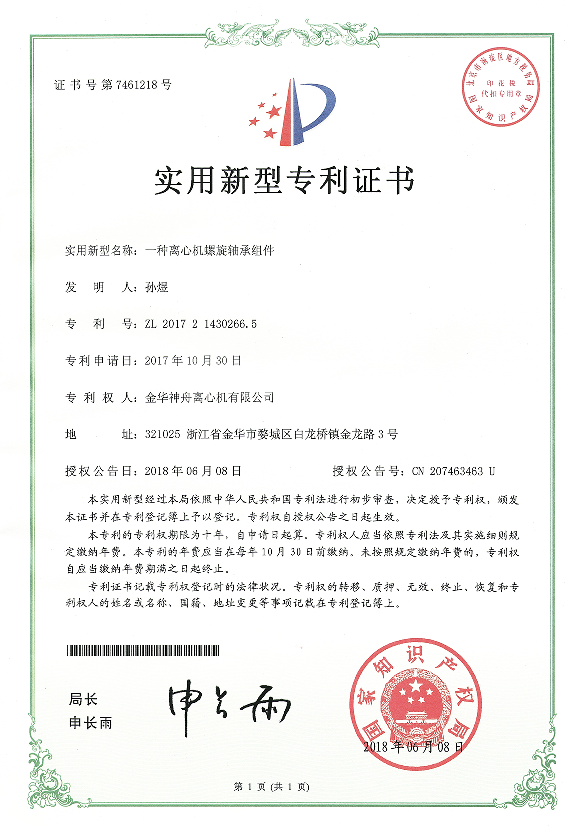

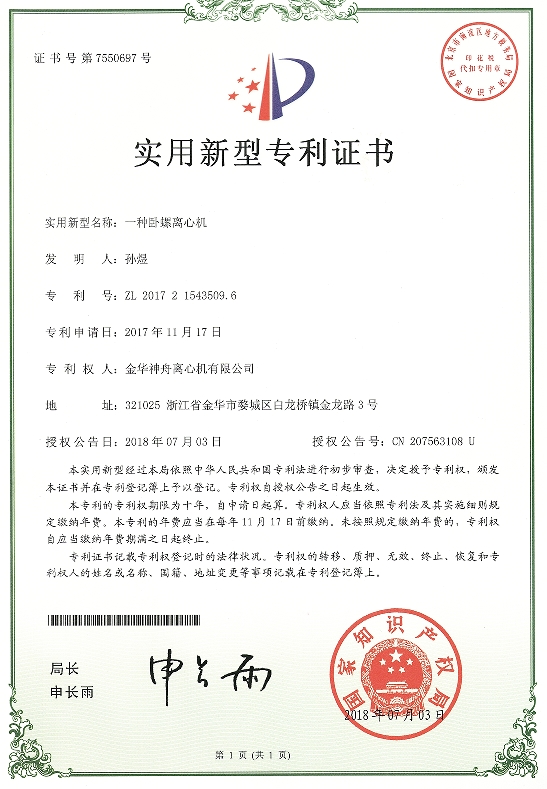

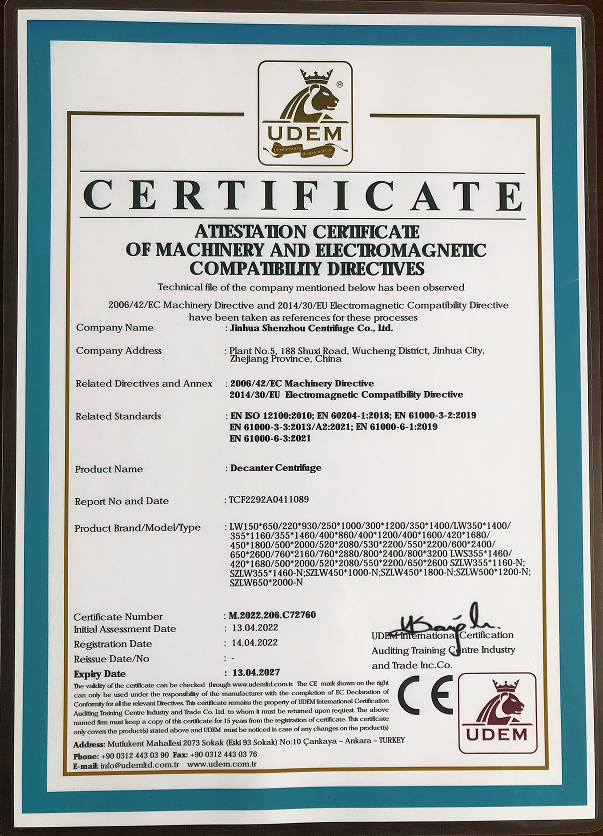

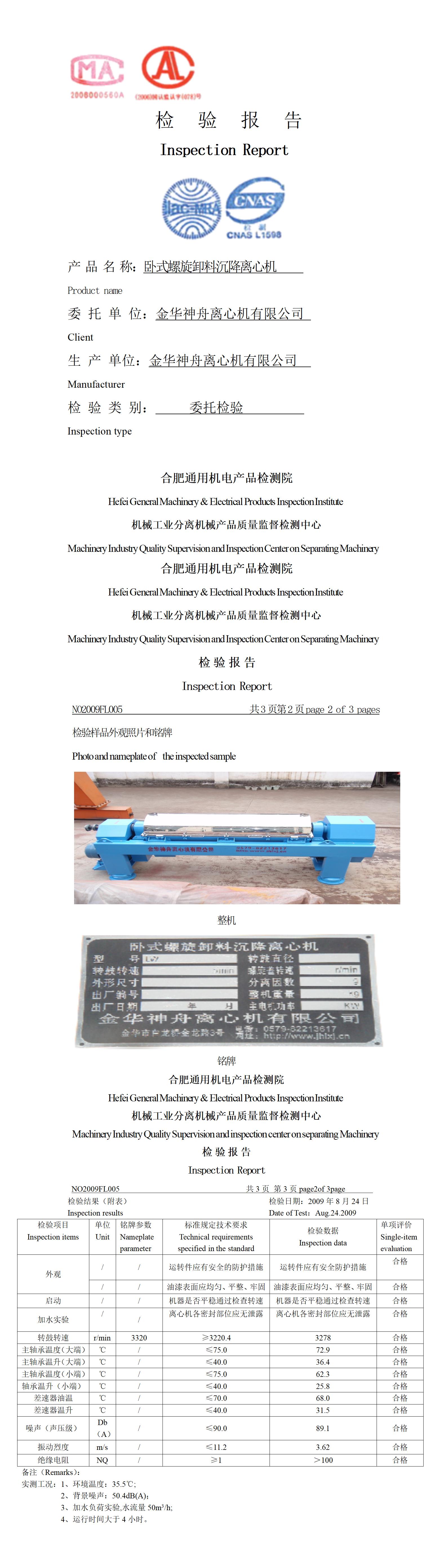

Certifications and Patents