Graphene Extraction Tubular Centrifuge High-Speed Separation Equipment for Industrial Production

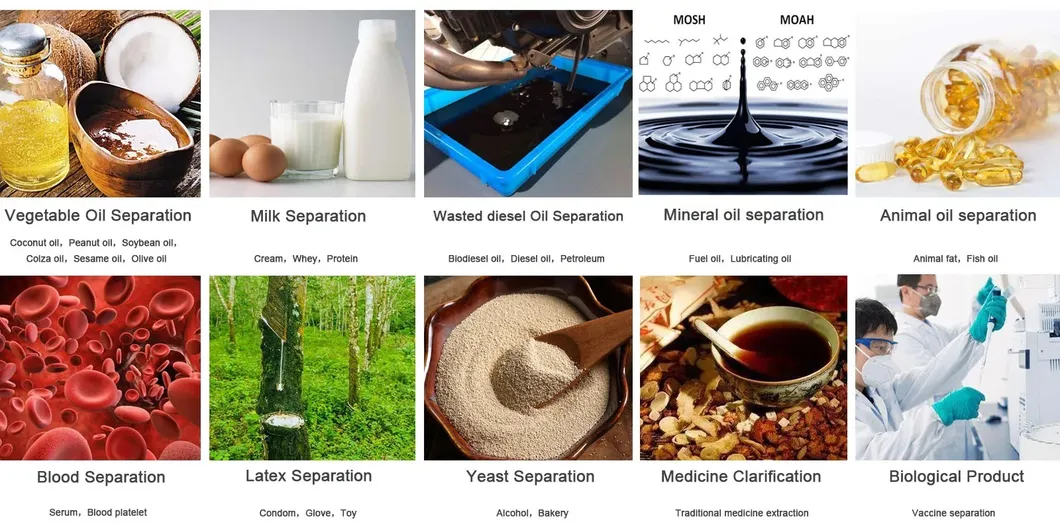

GF type tubular centrifuge is for water -oil-solid separation process. Widely used for plant oil, animal oil,waste engine oil separation . Such as VCO, Palm oil ,Avocado oil, Fish oil,Chicken oil,Beef oil, Olive oil,Seabucktorn oil. Tubular Centrifuge is manual discharging machine, So it is suitable for solid content lower than 5%. After separation, the solid phase will collect in the rotation bowl, need to stop centrifuge,for solid discharge.

3. Our machine has low noise!

4. We use S-K-F bearing,that would ensured the machine's quality

5. We also use Swiss bubble's bearing

6. All contact parts are made of SS304/SS316, ensured the oil or other material would reach the food grade!

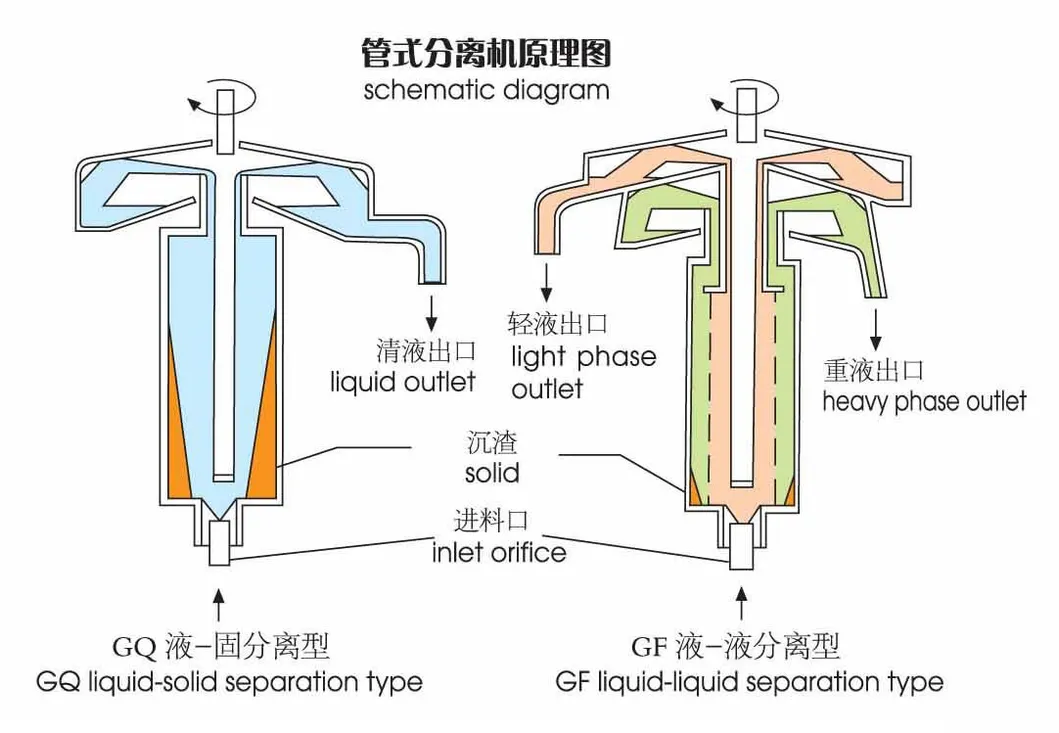

Consist of the machine cover, driving device, drum, liquid catch tray, the liquid inlet and bearing seat, this separator with high running speed, belongs to sedimentation separator. The upper drum is a flexible shaft, while the lower is damping floating bearing. The main shaft is connected by a coupling buffer and a passive wheel. Motor transmit power from the transmission belt and tension wheel to passive wheel, to drive the drum rotate around its own axis with high-speed, and thus form a strong centrifugal force field. All the materials are fed from liquid inlet under the bottom, and flow upward along the drum wall by centrifugal force fluid. During this process, the dense liquid phase forms the outer ring, and the small liquid phase forms the inner ring, which separately flow to respective liquid outlet mounted on the upper drum.

When the thickness of the sediment affect the liquid phase clarification or the capacity of the rated slag weight in the drum, the dregs of the drum wall should be removed manually after the shutdown.

Model Item | GQ75 | GF75 | GQ105 | GF105 | GFX105 | GQ150 | GF150 |

Inner Diameter (mm) | 75 | 75 | 105 | 105 | 105 | 142 | 142 |

Effective height (mm) | 450 | 450 | 730 | 730 | 730 | 730 | 730 |

Setting Volume (L) | 2.67 | 2.67 | 6 | 6 | 6 | 10 | 10 |

Rotary speed (r/min) | 20000 | 20000 | 19000 | 19000 | 19000 | 15000 | 15000 |

Max Separation factor | 17800 | 17800 | 21000 | 21000 | 21000 | 18000 | 18000 |

Feed Nozzle Diameter (mm) | 3,5,7 | 3,5,7 | 4,6,8 | 4,6,8 | 4,6,8 | 6,8,10 | 6,8,10 |

Feed Inlet Pressure (Mpa) | >0.05Mpa | ||||||

Production capacity (Kg/h) | ~670 | ~670 | ~1600 | ~1700 | ~1400 | ~3200 | ~3200 |

Motor power (kw) | 1.5 | 1.5 | 2.0 | 3.0 | 3.0 | 3.0 | 3.0 |

Dimension(L×W×H)mm | 500*700*1300 | 500*700*1300 | 600*1000*1600 | 600*1000*1600 | 600*1000*1600 | 600*1000*1600 | 600*1000*1600 |

Weight (Kg) | 300 | 300 | 450 | 450 | 460 | 580 | 590 |

Cooling pipe heat dissipation area (m²) | 0.38 | 0.38 | 1.4 | 1.4 | 1.4 | 1.4 | 1.4 |

Cooling pipe bearing pressure (Mpa) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | ||

High speed tubular centrifuge is an ideal instrument in biology, traditional medicine preparation, health food, chemistry for liquid separating and solid liquid separating. The minimum diameter of dissociative granule is 1 micron. It is especially separated for low differential proportion, small granularity, low solid content, strong medium corrosion, fuel distilled, and concentration and clarify. If you want to separate special material, please bring it to out company to do the separating test.

Details Images

emulsion, especially adaptable for liquid-liquid separation with slight gravity difference and liquid-liquid-solid separation with a little foreign matter, such as separation of various oil and micropowder, extract liquid from plants, separation of plasma and cell, separation of milk cream.