Source factory of tubular centrifuge manufacturers

Shenzhou Group Co., Ltd professionally engaged in design, manufacture, sale and installation of kinds of Centrifuge. We are one of the leaders of disc centrifuge, decanters, tubular centrifuge, separation system and marine equipment in China. Over the years, our products have been successfully applied in liquid-solid or liquid-liquid-solid separation of biomedicine, traditional Chinese medicine, phytoextraction, health foods, beverages, dairy products, lanolin, animal and plant oil, mineral oil, petroleum, chemical industry, environmental protection and other industries. For some materials with small difference in specific gravity of liquid and solid phase, small solid particle size and low content by use of centrifuge extraction, concentration and clarification, our company can provide you with ideal separation equipment.

High Speed Tubular Centrifuge, also called Tubular Bowl Separator, is a kind of fine separation equipment suitable for suspensions with thin concentration, fine particles, and small density difference solid-liquid separation, or liquid-liquid-solid separation. It is indispensable equipment for pharmaceutical, food, chemical, biological product, fermentation broth, beverages, blood products and other industries. High Speed Tubular Centrifuge working principle is that materials with different specific gravity are subject to different centrifugal forces when rotating at high speed, so as to achieve the purpose of separation.

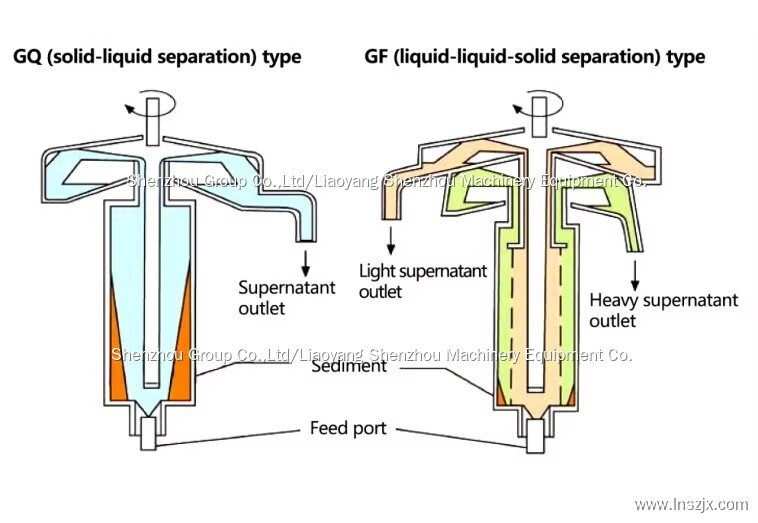

The centrifuge has high performance of separate factor, high capacity, and account for small area and easy to handle, it has t types, one is GQ two phase that can separate solid from the liquid, another is GF series, which can separate the water, solid from the oil.

GF model: Liquid with big density forms the outer liquid circle, while liquid with small density forms the inner circle. Then liquid will flow out of the upper outlet accordingly, and those little solid will be deposited on the drum wall, and be removed by manual after machine stops.

GQ model: Solid particles with big density are gradually deposited on the drum's inner wall, and forms sediment layer, after machine is stopped, is removed by manual. While the clarified liquid flows out through the outlet on the upper of the drum.

Working principle of Tubular Separator

Consist of the machine cover, driving device, drum, liquid catch tray, the liquid inlet and bearing seat, this separator with high running speed, belongs to sedimentation separator. The upper drum is a flexible shaft, while the lower is damping floating bearing. The main shaft is connected by a coupling buffer and a passive wheel. Motor transmit power from the transmission belt and tension wheel to passive wheel, to drive the drum rotate around its own axis with high-speed, and thus form a strong centrifugal force field. All the materials are fed from liquid inlet under the bottom, and flow upward along the drum wall by centrifugal force fluid. During this process, the dense liquid phase forms the outer ring, and the small liquid phase forms the inner ring, which separately flow to respective liquid outlet mounted on the upper drum.

When the thickness of the sediment affect the liquid phase clarification or the capacity of the rated slag weight in the drum, the dregs of the drum wall should be removed manually after the shutdown.

Product Paramenters

Model Item | GQ75 | GF75 | GQ105 | GF105 | GFX105 | GQ150 | GF150 |

Inner Diameter (mm) | 75 | 75 | 105 | 105 | 105 | 142 | 142 |

Effective height (mm) | 450 | 450 | 730 | 730 | 730 | 730 | 730 |

Setting Volume (L) | 2.67 | 2.67 | 6 | 6 | 6 | 10 | 10 |

Rotary speed (r/min) | 20000 | 20000 | 19000 | 19000 | 19000 | 15000 | 15000 |

Max Separation factor | 17800 | 17800 | 21000 | 21000 | 21000 | 18000 | 18000 |

Feed Nozzle Diameter (mm) | 3,5,7 | 3,5,7 | 4,6,8 | 4,6,8 | 4,6,8 | 6,8,10 | 6,8,10 |

Feed Inlet Pressure (Mpa) | >0.05Mpa | ||||||

Production capacity (Kg/h) | ~670 | ~670 | ~1600 | ~1700 | ~1400 | ~3200 | ~3200 |

Motor power (kw) | 1.5 | 1.5 | 2.0 | 3.0 | 3.0 | 3.0 | 3.0 |

Dimension(L×W×H)mm | 500*700*1300 | 500*700*1300 | 600*1000*1600 | 600*1000*1600 | 600*1000*1600 | 600*1000*1600 | 600*1000*1600 |

Weight (Kg) | 300 | 300 | 450 | 450 | 460 | 580 | 590 |

Cooling pipe heat dissipation area (m²) | 0.38 | 0.38 | 1.4 | 1.4 | 1.4 | 1.4 | 1.4 |

Cooling pipe bearing pressure (Mpa) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |