HR Pusher Type Centrifuge is a type of filtering centrifuge

characterized by continuous feeding and intermittent discharging.

Pusher Type Centrifuge is a continuous filtering type centrifuge used for solid-liquid separation in the chemical and mineral industries. Pushers have been used for more than 60 years for dewatering relatively large, free-draining crystals. The Pusher Type Centrifuge has a unique design that minimizes moisture, impurity and crystal breakage in discharged cake.

HR Pusher Type Centrifuge is a type of filtering centrifuge characterized by continuous feding and intermittent discharging.

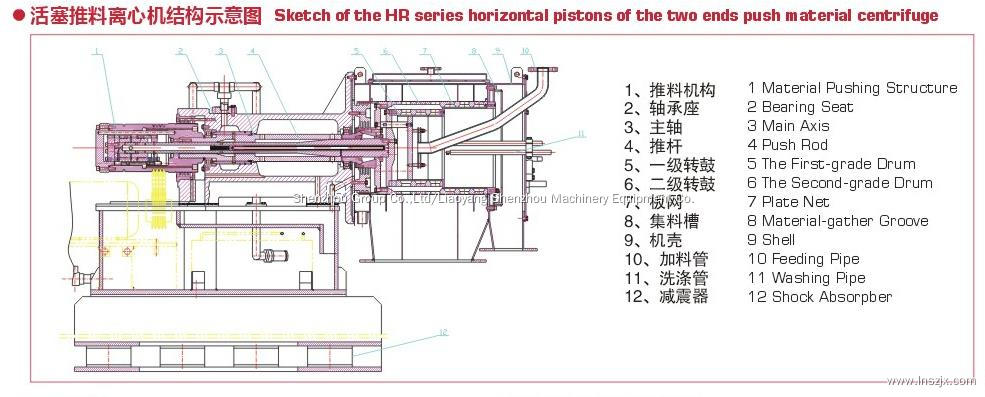

Composed of hydraulic system, pushing mechanism, base, enclosure, transmission mechanism, basket,etc., this product is able to realize continuous feeding, separation, washing, discharging and other processes at full speed.

SCOPE OF APPLICATIONS

Scope of Application

Solid particle size >0.08MM

Concentration of 40%-80% (mass percentage)

Material viscosity <10-1PA.S

Industrial Application

This product is applicable to the filtration of sodium chloride, ammonium chloride, ammonium bicarbonate, urea, polyethylene, polypropyl ethylene, ammonium nitrate, oxalic acid, sodium sulfate, caffeine, etc. in the chemical, fertilizer, alkali production, salt production and other industries.

Pusher Type Centrifuge working principle

The Pusher Type Centrifuge has a basket rotating around a horizontal axis, and it uses centrifugal force for separating the solid and liquid. Hydraulic system gives the force to a piston, and wet materials are exited from discharge basket.

The pushing plate is hydrauli, and a sufficient amount of oil is provided to this hydraulic system through shaft pumps that assembled vertically to the crankcase.

Machine base supports the pusher and provides a chamber for hydraulic oil. Hydraulic mechanism is driven by an operating valve. Thanks to piston motions, solid that separate with the liquid is discharged from a discharge chamber.

Gentle product acceleration avoids particle breakage and abrasion

Slurry is smoothly accelerated up to rotating speed by the optimized and application-specific geometry of our feeding system

Solids recovery of up to 99% can be achieved as particle breakage is avoided

Homogeneous product distribution leads to smooth operation and high filtration rates

Pre-filtration Technology: Maximum flexibility and high liquid capacity due to internal thickening

By maintaining a free draining area at each phase of the pushing cycle, the Pre-filtration Technology significantly increases the liquid capacity of the centrifuge

Minimum particle breakage with optimized feed system.

First choice for applications with low solids concentration, highly viscous liquids, varying feed conditions

Cartridge design for maximum uptime and easy maintenance

The rotating assembly can be removed as a cartridge in one piece without disconnecting the piping

The original cartridge can be replaced by a spare cartridge and undergo maintenance in our service center

Overall downtime for replacement is less than 8 hours

In-depth process know-how and lab testing facilities

With experience in hundreds of different applications our process engineers know in detail what is happening inside our centrifuge and what is to be expected in your installation

In our state of the art lab we can offer you a broad range of tests, from small scale feasibility studies to full scale equipment tests everything is possible

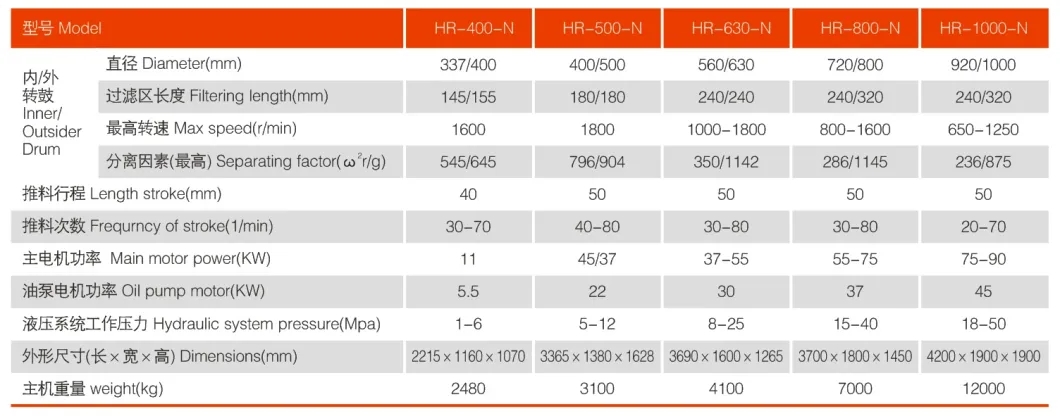

MAIN TECHNICAL PARAMETERS:

PARTS OF THE PUSHER CENTRIFUG

Suspension Input

The pusher centrifuge is fed continuously from this input with solid-liquid mixture.

Suspension Distributor

Solid-liquid mixture is expedited at the first basket stage and disperses to all place.

First Basket

Biggest part of liquid (approximately %80) is filtered at this stage. Also, the first basket stage makes axial thrust motion.

Second Basket

Solid-liquid mixture is pushed to the second basket, and liquid amount decreases.

Solid Discharging Chamber

Solid remove from this chamber.

Filter Cage

Liquid that removes from solid is taken from the filtration reservoir.

Flushing Nozzle

The process area is washed as spraying washing liquid. Thus, salt crystals don't become in the screens and accumulation of waste is prevented.

|  |

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1