Three-Phase Decanter Centrifuge Lws520 For Waste Oil Treatment

Three-phase decanter centrifuge is that two liquid phases and one solid phase enter the centrifuge and expand it thousands of times by relying on the centrifugal force field. The solid phase is settled under the action of centrifugal force, and the two liquid phases are also stratified, so as to realize Solid-liquid-liquid 3-phase separation and discharge them from the body under the action of special mechanism. The whole feeding and separation process is continuous, closed and automatic. (solid-liqui-liquid separation)

Shenzhou Machinery Three-phase decanter centrifuge is widely used in the production of chemical, printing, metallurgical coal mine, oil production, metallurgy, iron and steel, fabric, food, drink, starch, dyes and so on, and it can also solve industrial and municipal wastewater. By use it, solid can be dehydrated, liquid can be clarified. The application of horizontal screw decanter centrifuge in environmental protection mainly refers to the dehydration of sludge produced in the process of industrial and civil sewage treatment. Nowadays, environmental problems have become the focus of the world. In this context, the value of horizontal screw decanter centrifuge has been reflected. Because of its inherent characteristics of large processing capacity, automatic operation and good dehydration effect, horizontal screw decanter centrifuge has been widely used and promoted in the field of environmental protection.

3 Phase Decanter Centrifuge Working Principle

➢Precision Feeding

The mixed slurry enters through a central feed pipe into the high-speed rotating bowl

Advanced distribution systems ensure smooth acceleration and even flow distribution

➢Multi-Stage Separation

Under intense centrifugal forces (typically 2,000-4,000 × G):

Heavy solids migrate toward the bowl's outer wall

Heavy liquid phase forms an intermediate concentric layer

Light liquid phase remains as an inner cylinder near the rotational axis

➢Intelligent Phase Recovery

Solids Conveying: Helical scroll conveyor transports settled solids to discharge ports

Liquid Extraction:

Heavy liquid phase: Regulated discharge through adjustable gravity disc system

Light liquid phase: Controlled removal via centripetal pump discharge

All three phases discharge continuously and simultaneously

Common Applications

➢Oil & Gas Industry

Treatment of drilling muds and slop oils

De-oiling of produced water

Recovery of valuable oils from tank bottoms

➢Food Processing

Purification of edible oils and fats

Separation in biodiesel production

Processing of animal by-products

➢Environmental Technology

Treatment of industrial wastewater

Processing of marine bilge water

Recycling of industrial lubricants

➢Chemical & Pharmaceutical

Catalyst recovery and purification

Separation of chemical intermediates

Pharmaceutical product refinement

➢Technical Advantages

Continuous 24/7 operation capability

Compact footprint with high processing capacity

Minimal operator intervention required

Adaptable to various industry-specific requirements

Compliance with international safety and environmental standards

| Product Name | 3-Phase Horizontal Decanter Separation Centrifuge Equipment |

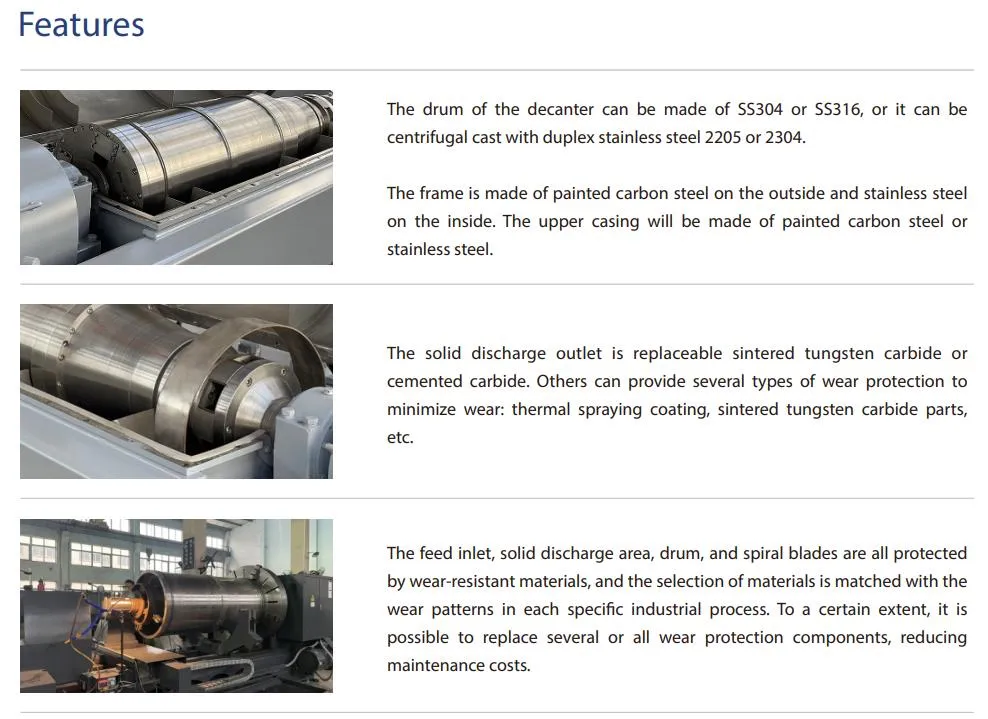

| Material | SS304/Duplex |

| Drum Diameter | 520mm |

| Main Motor | 55KW/380V/50HZ |

| Auxiliary Motor | **** |

| Maximum Speed | 3500 r/min |

| Maximum Separator Factor | 3154g |

| Capacity | 5 m3/h |

| Weight | 5000 kgs |

| Product Dimension | 4150x1410x1170mm |

| HS Code | 8421192000 |