Passion Juice and Lemon Juice Solid-liquid Separation and Filtration Type Flat Hanging Bag Centrifuge

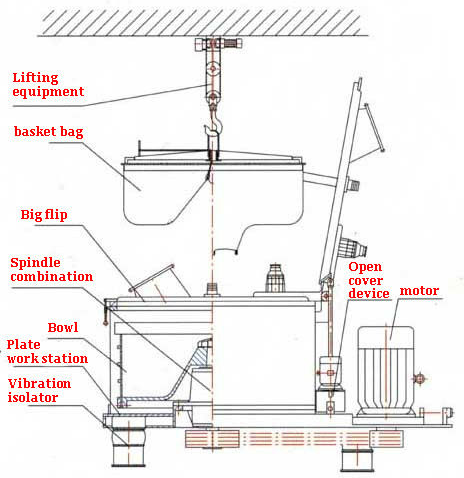

The Flat Bag Centrifuge is a closed structure filtration equipment, which is composed of driving device, body, casing, drum, hanging bag, brake device, clutch and other components. The materials are added into the drum from the upper part. Under the action of centrifugal force field, the liquid phase passes through the filter medium and is discharged out of the machine. The solid phase is trapped in the drum. After the machine is stopped, the liquid blocking plate and the filter bag are lifted out together to the designated place place to unload.

Features and Advantages:

centrifuge shell, the inner and outer surface of the drum, the surface of the liquid collecting tank and other invisible parts of the centrifuge, which meets the GMP specification.

Working principle

Flat bag centrifuge is a kind of filter intermittent operation centrifuge. The drum baffle plate and the filter bag are fixed together. The baffle plate and the drum are fixed by bolts. After feeding, the solid phase is separated by filtration. The solid phase forms filter cake in the filter bag. Stop the machine to release the bolts and use the electric hoist to lift the filter bag out for unloading, thus forming a working cycle. The cycle can be completed 3-8 times per hour. The drum is started by the transmission part equipped with clutch to generate centrifugal force field. The filtrate injected into the drum is separated through the filter bag lined in the drum, and the filter residue is trapped in the drum. The filtrate is led into the collection container through the liquid outlet pipe. When the charging limit is reached, stop feeding, cut off the power supply, and stop the drum operation with the brake device (the brake unit can be used when equipped with frequency converter) Open the machine cover, lift the filter bag out of the machine body with lifting tools, and discharge, that is to complete a working cycle.

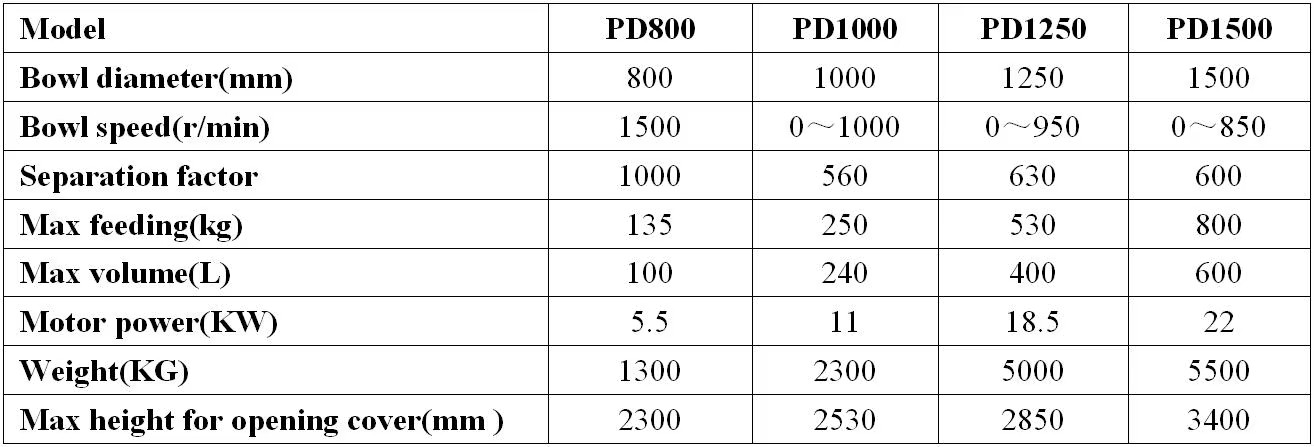

| Parameter |