Shenzhou Expert's Discussion on Horizontal Spiral decanter Centrifuge

|  |

The working principle of decanter centrifuge is: that the drum and screw rotate at a certain speed difference in the same direction at high speed. The material continuously enters the inner cylinder of the feeding screw through the feeding pipe, accelerates, and enters the drum. Under the action of the centrifugal force field, heavier solid particles deposit on the wall of the drum to form a sediment layer. The feeding screw continuously pushes the deposited solid matter to the cone end of the drum, and it is discharged from the machine through the slag discharge port. The lighter liquid phase forms an inner liquid ring, which continuously overflows from the overflow port at the large end of the drum and is discharged outside the machine through the discharge port. This machine can continuously feed, separate, wash, and discharge at full speed. It has the characteristics of compact structure, continuous operation, smooth operation, strong adaptability, large production capacity, and convenient maintenance. Suitable for separating suspensions containing solid particles with a particle size greater than 0.005mm and a concentration range of 2-40%. Widely used in industries such as chemical, light industry, pharmaceuticals, food, and environmental protection

Model choosing :

Choosing a suitable horizontal screw centrifuge can not only solve production problems and improve work efficiency, but also save production costs and reduce business risks. The main factors that affect selection are as follows:

1. The speed of the centrifuge: Generally, the horizontal screw centrifuge should be above 3000 rpm. The higher the speed, the higher the separation factor of the centrifuge, and the better the separation effect.

2. Material of Centrifuge: Different materials have different physical and chemical indicators such as wear resistance and corrosion resistance. Generally, the lowest material for foreign horizontal screw centrifuges is 316L or duplex stainless steel, and ceramic composite materials must be used for wear and corrosion components.

3. Differential control of centrifuges: Different differentials have different control accuracies, and there is a significant difference in lifespan and maintenance costs. The higher the differential accuracy, the better the adaptability to materials. Therefore, it is advisable to choose equipment with high differential accuracy.

4. Length to diameter ratio: The larger the length to diameter ratio of a horizontal screw centrifuge, the greater its processing capacity and the lower its moisture content.

5. Control system: Whether it is automated programming control, domestic and foreign equipment manufacturers have basically achieved full automation control of the equipment.

6. Installation power: affects energy consumption control, generally domestic equipment has a high energy consumption ratio, while foreign equipment has a low energy consumption ratio.

7. Processing and manufacturing technology: The horizontal screw centrifuge is a separation equipment that requires high-precision processing. Enterprises without precision processing capabilities produce products with high maintenance rates and limited processing capabilities.

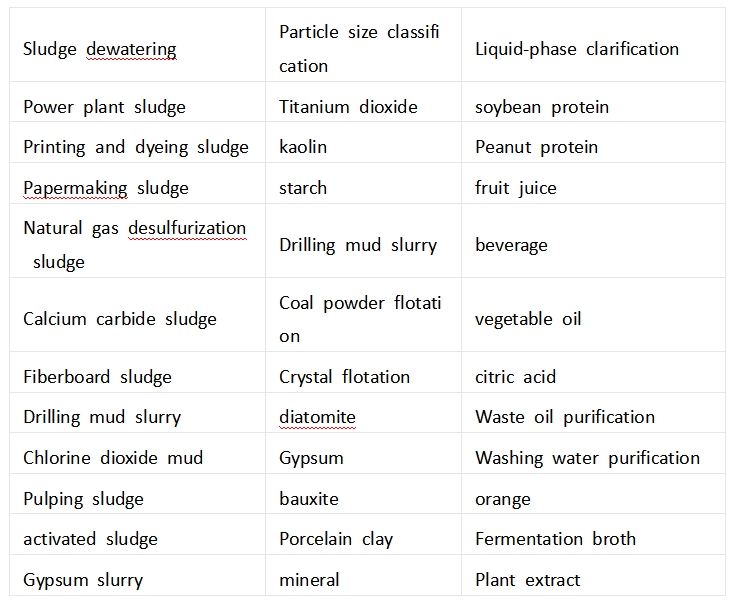

Application industry:

Environmental status

The horizontal screw centrifuge mainly refers to the dewatering of sludge generated in industrial and civil sewage treatment processes in environmental protection applications. Today's environmental issues have become a global concern, and in this context, the value of horizontal screw centrifuges has been reflected. Previously, sewage plants or related treatment plants used self settling or belt filter presses for sludge dewatering and concentration. Experiments have shown that the sludge moisture content has decreased from 98% to 80%, and its volume can be reduced by 10 times. Therefore, horizontal screw settling centrifuges have been widely used and promoted in the field of environmental protection due to their inherent characteristics of large processing capacity, automated operation, and good dewatering effect. The single product sales of the horizontal screw centrifuge account for about half of all centrifuge products, establishing its irreplaceable position. In foreign countries, horizontal screw centrifuges are preferred for sewage treatment equipment.

Separation

1: Adopting involute planetary gear differential, with large transmission ratio and high accuracy.

2: The entire machine is equipped with a mechanical and electrical dual overload protection device, ensuring safe use.

3: The main motor of the power frequency speed regulation type is equipped with a hydraulic coupling, and the motor runs smoothly.

4: High quality stainless steel material with strong corrosion resistance is selected for the contact area with materials.

5: The whole machine adopts an integral frame structure, which is safe and convenient for lifting, and occupies a small area.

6: The explosion-proof level of power frequency and variable frequency electrical appliances is Exd Ⅱ BT4, and the sealing performance of the control box is good.