3 Phase Decanter Centrifuge: Efficient Solid-Liquid Separation

Product features

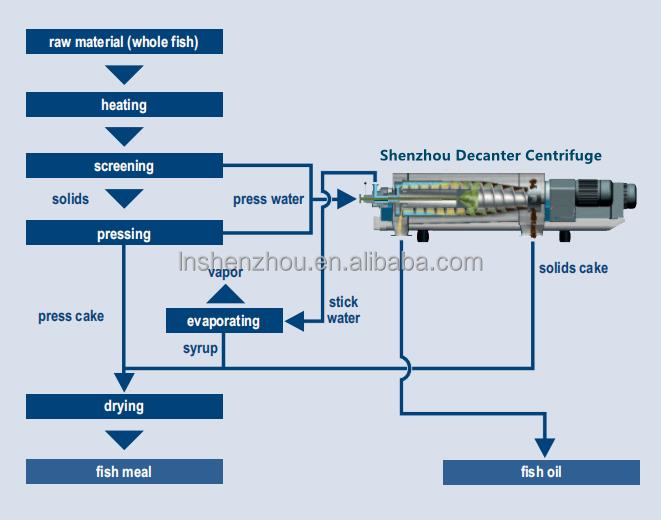

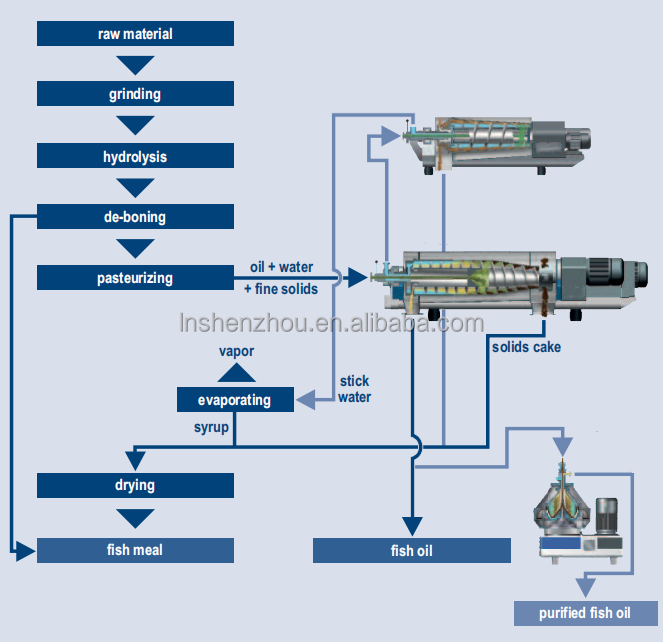

The 3 phase decanter centrifuge offers efficient solid-liquid separation with key features such as reduction of beer evaporation, gentle processing of beer, and yeast cake with a high dry substance content. This industrial centrifuge plays a key role in processes for recovery of fish meal and fish oil with high performance, separation efficiency, and reduced emissions of odors or vapors. With a variety of models available, the decanter centrifuge is suitable for separating solid from liquid in various applications, offering high reliability, cost efficiency, and easy integration into existing processes.

We serve

We serve as a reliable solution for efficient solid-liquid separation with our 3 Phase Decanter Centrifuge. Our product is designed to deliver superior performance and streamline industrial processes, ensuring optimal output and cost-effectiveness. With a focus on precision and quality, we aim to meet the needs of our customers in various industries by providing a reliable and versatile separation solution. Our commitment to innovation and customer satisfaction drives us to deliver exceptional service and support. Trust us to serve you with a high-quality product that enhances the efficiency of your operations.

Enterprise core strength

At our company, we serve as industry leaders in providing efficient solid-liquid separation solutions with our 3 Phase Decanter Centrifuge. With a commitment to excellence, we strive to deliver high-quality products that meet the needs of our customers. Our team of experts is dedicated to serving you by providing innovative technology, superior performance, and reliable service. Whether you are in the mining, food processing, or wastewater treatment industry, our centrifuge is designed to streamline your operations and improve your productivity. Trust us to serve you with the best solutions for your solid-liquid separation needs.

Product Description

Fish Oil Sludge decanter centrifuge to separate solid from liquid

When mixed fluid enters rotating bowl of centrifuge through feed tube ,solids with larger density would rapidly deposit on inner wall of the bowl,forced by centrifugal acceleration.Then spiral pusher pushed deposited solids to taper end of the bowl,and discharges them out of centrifuge from residual outlet.Meanwhile ,liquid phase with smaller density forms a liquid ring layer and discharges from bowl through overflow port,the bowl and spiral pusher run at a high speed simultaneously ,for there exists speed discrepancy,deposited solids on the wall of bowl could be conveyed to residue outlet by spiral pusher.This separation process carry out continuously.

Separation technique

Feeding-gravitational separation-liquid discharge-sediment discharge.

Separation effect factors Centrifuging factor ,length to diameter ratio of cavity ,depth of fluid pool.

Field control

Bowl rotating speed ,rotative speed difference,between,spiral pusher and bowl depth of liquid pool.

Advantages and features

* Gentle processing of beer

* Yeast cake with a high dry substance content

* Lower wastewater loads

* Easy to integrate into existing processes

Model | Diameter(mm) | Lenght(mm) | Max speed | L/D ratio | G-force | Capacity(m3/h) | Main motor power(Kw) | Weight(kg) | Dimension (mm) |

LW250*1000 | 250 | 1000 | 5000 | 4 | 2722 | 0.5-5 | 7.5 | 950 | 2120*1250*680 |

LW300*900 | 300 | 900 | 4200 | 3 | 2964 | 1-6 | 11 | 1160 | 2150*1300*900 |

LW300*1200 | 300 | 1200 | 4000 | 4 | 2784 | 2-6 | 11 | 1350 | 2450*1300*900 |

LW355*1160 | 355 | 1160 | 3600 | 3.3 | 2576 | 2-8 | 15 | 1400 | 2470*1350*830 |

LW355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 1800 | 2750*1350*830 |

LW400*1200 | 400 | 1200 | 3200 | 3 | 2294 | 3-12 | 18.5 | 1800 | 2730*1600*1080 |

LW400*1600 | 400 | 1600 | 3000 | 4 | 2016 | 3-15 | 22 | 2000 | 3130*1600*1080 |

LW450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 2500 | 3320*1700*1130 |

LW500*2000 | 500 | 2000 | 2800 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

LW530*1855 | 530 | 1855 | 2600 | 3.5 | 2006 | 5-38 | 55 | 4680 | 3885*1350*1600 |

LW530*2120 | 530 | 2120 | 2400 | 4 | 1709 | 5-40 | 55 | 4800 | 4150*1350*1600 |

LW550*2000 | 550 | 2000 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

LW650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

LW650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490*1510*1720 |

LW720*2160 | 720 | 2160 | 2000 | 3 | 1612 | 7-80 | 120 | 6000 | 5200*1600*1800 |

LW720*2880 | 720 | 2880 | 2000 | 4 | 1306 | 7-90 | 120 | 8000 | 3100*1600*1800 |

LW800*2400 | 800 | 2400 | 1800 | 3 | 1451 | 20-100 | 150 | 12000 | 5820*2000*1300 |

LW800*3200 | 800 | 3200 | 1800 | 4 | 1451 | 20-120 | 150 | 1300 | 7100*2000*1300 |

Screw production1

Screw production2:

High speed dynamic balance detection1

High speed dynamic balance detection2

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.