3 Phase Decanter Centrifuge: Optimal Palm Oil Separation

Product features

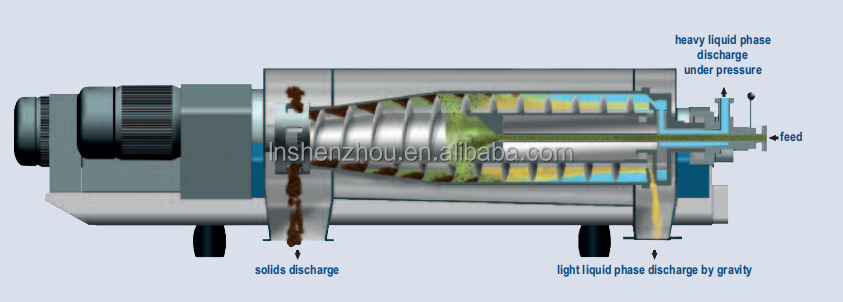

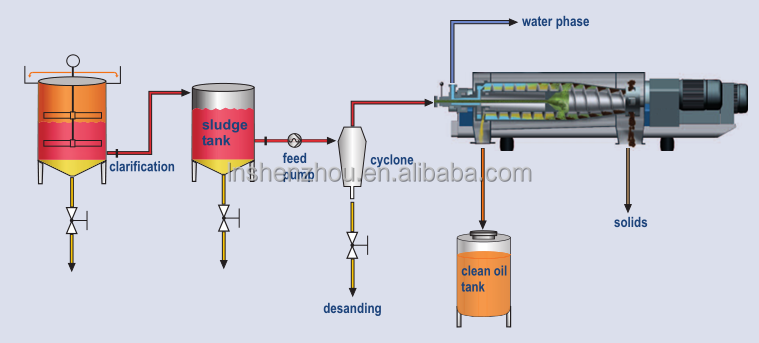

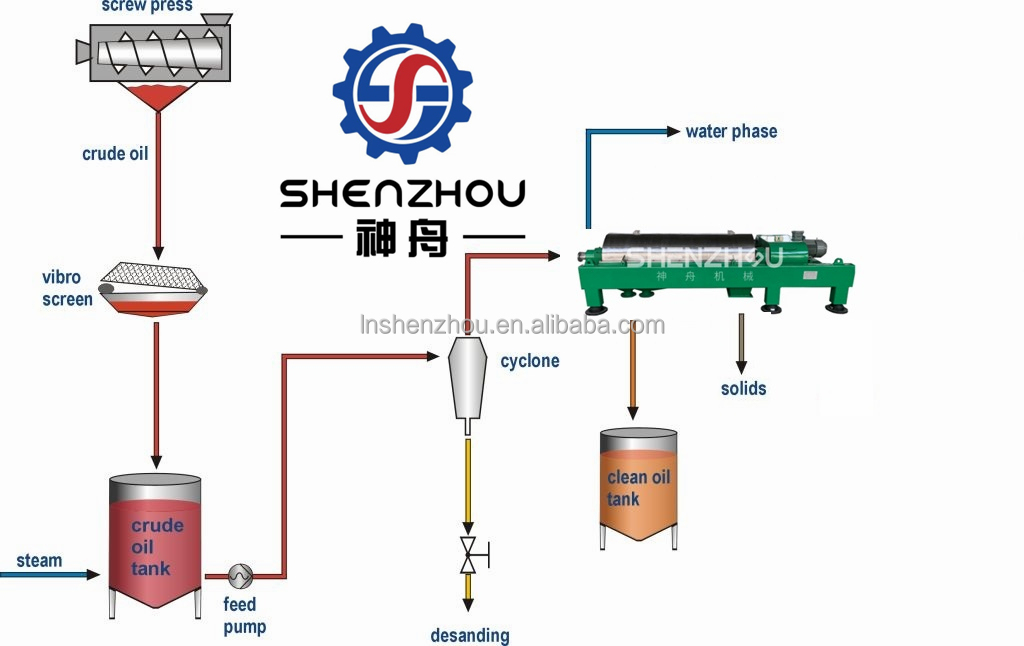

The 3 Phase decanter centrifuge by Shenzhou offers optimal palm oil separation with a unique design that eliminates shear force during product feed, resulting in improved oil recovery and less stress. The pipette device allows for easy adjustment of oil purity requirements and minimizes oil losses in the heavy phase. With a variety of sizes available, ranging from LW250*1000 to LW800*3200, this decanter centrifuge caters to the needs of palm oil producers and users, providing better separation and optimizing yield.

Company profile

With a commitment to delivering innovative separation solutions, our company specializes in producing high-quality 3 Phase Decanter Centrifuges for optimal palm oil separation. Our state-of-the-art equipment is designed to efficiently separate oil, water, and solids, maximizing productivity and yield in the palm oil industry. With a focus on quality, reliability, and performance, we strive to meet the unique needs of our customers and exceed their expectations. Trust in our expertise and experience to provide you with the best separation solutions for your palm oil processing operations. Choose our 3 Phase Decanter Centrifuge for superior performance and results.

Why choose us

With a commitment to providing innovative solutions for efficient palm oil separation, our company is proud to offer the 3 Phase Decanter Centrifuge. Our state-of-the-art equipment is designed to optimize the process of separating oil, water, and solids, resulting in higher quality palm oil production. With a focus on reliability and performance, our decanter centrifuge is built to withstand the rigorous demands of the palm oil industry. Backed by our team of experts and years of experience, we are dedicated to providing our customers with the best possible solution for their palm oil separation needs. Trust in our company to deliver superior results every time.

Product Description

Horizontal Industrial Decanter Centrifuge Machine Palm Oil Sludge Separation Waste Mud Decanter Centrifuge

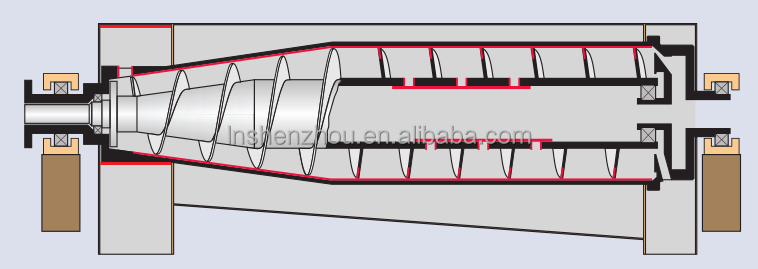

The liquid phase of the Shenzhou decanter centrifuge is discharged under pressure (1.5 to 2 bar) in both 2- and 3-phase configurations by means of a skimmer (also named “pipette”) that can be adjusted at millimeter intervals during operation. The flexibility of the ANDRITZ pipette design allows the user to adjust removal of liquid phase instantly without having to stop the machine or loosen any nuts. This enables the palm oil mill operator to extract the best oil quality or to adapt to any change in process conditions. The system provides better separation and optimizes the yield.

Model | Diameter(mm) | Lenght(mm) | Max speed | L/D ratio | G-force | Capacity(m3/h) | Main motor power(Kw) | Weight(kg) | Dimension (mm) |

LW250*1000 | 250 | 1000 | 5000 | 4 | 2722 | 0.5-5 | 7.5 | 950 | 2120*1250*680 |

LW300*900 | 300 | 900 | 4200 | 3 | 2964 | 1-6 | 11 | 1160 | 2150*1300*900 |

LW300*1200 | 300 | 1200 | 4000 | 4 | 2784 | 2-6 | 11 | 1350 | 2450*1300*900 |

LW355*1160 | 355 | 1160 | 3600 | 3.3 | 2576 | 2-8 | 15 | 1400 | 2470*1350*830 |

LW355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 1800 | 2750*1350*830 |

LW400*1200 | 400 | 1200 | 3200 | 3 | 2294 | 3-12 | 18.5 | 1800 | 2730*1600*1080 |

LW400*1600 | 400 | 1600 | 3000 | 4 | 2016 | 3-15 | 22 | 2000 | 3130*1600*1080 |

LW450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 2500 | 3320*1700*1130 |

LW500*2000 | 500 | 2000 | 2800 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

LW530*1855 | 530 | 1855 | 2600 | 3.5 | 2006 | 5-38 | 55 | 4680 | 3885*1350*1600 |

LW530*2120 | 530 | 2120 | 2400 | 4 | 1709 | 5-40 | 55 | 4800 | 4150*1350*1600 |

LW550*2000 | 550 | 2000 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

LW650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

LW650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490*1510*1720 |

LW720*2160 | 720 | 2160 | 2000 | 3 | 1612 | 7-80 | 120 | 6000 | 5200*1600*1800 |

LW720*2880 | 720 | 2880 | 2000 | 4 | 1306 | 7-90 | 120 | 8000 | 3100*1600*1800 |

LW800*2400 | 800 | 2400 | 1800 | 3 | 1451 | 20-100 | 150 | 12000 | 5820*2000*1300 |

LW800*3200 | 800 | 3200 | 1800 | 4 | 1451 | 20-120 | 150 | 1300 | 7100*2000*1300 |

Screw production1

Screw production2:

High speed dynamic balance detection1

High speed dynamic balance detection2

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.