Our Efficient Low Temp Hemp CBD Centrifuge Machine is designed to provide maximum extraction of CBD oil at a low temperature, preserving the potency of the cannabinoids and terpenes. With a high-speed centrifuge, this machine can process large quantities of hemp efficiently and effectively. Its innovative design and advanced technology make it a standout choice for hemp oil producers looking to optimize their production process.

Our company specializes in designing and manufacturing cutting-edge machinery for the hemp CBD industry. With a focus on efficiency and innovation, we have developed the Efficient Low Temp Hemp CBD Centrifuge Machine to meet the needs of our discerning customers. Our team of experts is dedicated to providing high-quality equipment that maximizes productivity and profitability for our clients. We take pride in our commitment to delivering reliable and durable solutions that help businesses thrive in the competitive CBD market. Trust us to provide the tools you need to succeed in this rapidly growing industry.

Our company specializes in designing and manufacturing efficient low-temperature Hemp CBD Centrifuge Machines that are perfect for extracting high-quality CBD oil from organic hemp plants. With a focus on innovation and sustainability, we strive to provide our customers with top-of-the-line equipment that delivers exceptional results while minimizing energy consumption. Our machines are built to last, using durable materials and reliable components to ensure smooth operation and consistent performance. Trust in our expertise and dedication to quality to take your CBD extraction process to the next level. Experience the difference with our Hemp CBD Centrifuge Machines.

thanol Centrifuge Extractor For Hemp CBD Oil

The LCE Series extraction centrifuges focus on extracting the hemp and other plant species you need. High-purity extraction of specific plants is efficiently performed by a programmable touch control program.

6 Advantages Of CBD Centrifugal Extractor

1. LCD touch screen, PLC controller system. Frequency control cabinet. Explosion proof motor.

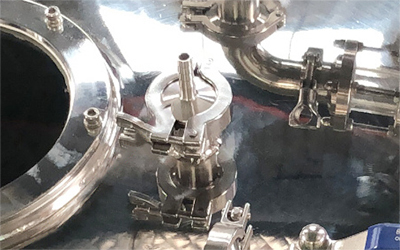

2. Large visible window, can observe working condistion easily and clearly.

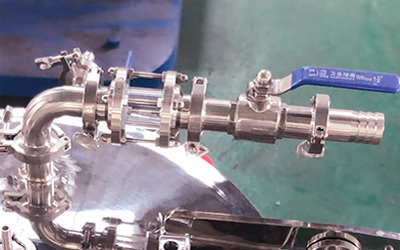

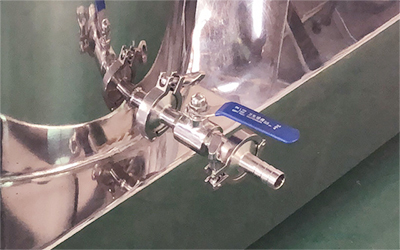

3. Ethanol feeding port with valve.

4. Vacuum port with quick clamp, can match vacuum pump for negative pressure feeding.

5. Discharge port with controller valve.

DESCRIPTION

The LCE Series Centrifuge is an all-in-one system that combines closed low temperature alcohol extraction with mechanical centrifugation. With PLC controller and LCD touch screen, with forward/reverse/dehydration functions and the ability to set the time and number of cycles, all of which can be programmed according to actual usage for more efficient separation. The system's one-cycle run time is approximately 10-15 minutes, ensuring high quality raw extracts in a short period of time.

FEATURES

1. 98% plant extraction rate

2. 97% alcohol removal rate

3. The part in contact with the materials made of SUS304 or SUS316L, and the surface is treated with sanitary grade and no dead angle, easy to clean.

4. The inlet port and outlet port adopt a hygienic quick clamp with a valve.

5. All seals are sealed with PTFE or fluorine rubber, and the main shaft is double-layer fluorine seal water seal/oil seal.

6. Explosion proof motor with 220V 3phase (220V single-phase is optional), PLC and touch screen control, frequency conversion control cabinet.

7. Equipped with two inlet/intake tubes, one vacuum port with valve, one drain port, inlet and outlet port for recirculating chiller.

8. The cylinder is jacketed type, can connect with recirculating chiller for cooling.

9. The base is equipped with four lifting rings for easy loading and unloading.

10. Equipped with 10m cable and control cable, can use it directly after electrical connection.

Extraction cycle:

The LCE series centrifuge extractor offers 3 program cycles: spray wash, stirred wash and spin dry cycle. Each program cycle can be run automatically or manually. The operator loads the ground plant material into a filter bag and places it in a centrifuge, rotating it at different speeds in the system while injecting alcohol at a controlled rate. The centrifuge can also be submerged and stirred in both directions to completely extract the cost of the plant. After washing, the plant material is subjected to high-speed spin-drying to remove 97% of the residue on the plant material, and the active ingredient extraction rate is as high as 98%. The alcohol wash can be recycled 2-3 times or directly for further processing.

1) System loading

Place the filter bag filled with plants into the drum and seal the system.

2) Cleaning cycle

Select the speed and time of forward and reverse rotation in the program menu to perform the spray washing operation.

3) Alcohol filling

A pneumatic pump is used to pass the low temperature ethanol through the inlet pipe into the system.

4) Extraction begins

The plant material in the centrifuge is stirred and washed, and a certain number of two-stage agitation cycles are set, so that 98% of the plant active ingredient can be extracted.

5) System drainage

After the cleaning cycle is complete, open the outlet valve venting system. The alcohol wash is pneumatically pumped to a suitable reservoir for further processing.

6) High speed dehydration

Select the “Dehydration” program on the program menu to start the high speed dehydration cycle. Thoroughly dry the alcohol solution on the wet plant surface.

| Model | HHP-15 | HHP-25 | HHP-45 | HHP-65 | HHP-115 | HHP-145 | HHP-250 |

| Capacity (L) | 15 | 25 | 45 | 65 | 115 | 145 | 250 |

Drum diameter (mm) | 300 | 300 | 450 | 450 | 600 | 600 | 800 |

Drum height (mm) | 250 | 350 | 300 | 400 | 400 | 500 | 500 |

| Rotational speed(RPM) | 2000 | 2000 | 1500 | 1500 | 1250 | 1250 | 1100 |

Motor power (Kw) | 1.1 | 1.5 | 2.2 | 3 | 4 | 5.5 | 11 |

Dimension (mm) | 1100*650*1020 | 1100*650*1020 | 1400*850*1080 | 1400*850*1080 | 1600*1060*1250 | 1600*1060*1330 | 1700*1400*1600 |

| Weight(kg) | 240 | 260 | 450 | 470 | 1000 | 1030 | 1350 |

| Motor | Explosion proof motor | ||||||

| Control | PLC controller, LCD touch screen | ||||||

| Material | Stainless steel material | ||||||

WHY CHOOSE US Factory direct sales with competitive price. Premium quality with CE & ISO certification. Strong product OEM & ODM customization capability. Promise production & on-time delivery. Perfect after-sales service, free product accessories. 15 years of experience in R&D and production of centrifugal extractor machine. | |||||||

In essence, a long-standing centrifugal diesel fuel filter organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Regarding the attributes and functionality of the centrifugal diesel fuel filter, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Yes, if asked, we will supply relevant technical details regarding Shenzhou. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd, most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Pusher Centrifuge and an unforgettable experience of partnering with us.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. centrifugal diesel fuel filter QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1