Shenzhou 3 phase decanter centrifuge is mainly designed for Solid-liquid-liquid three-phase separation of materials.With our over 40 years of experience in the separation industry, it is the most advanced type machine for 3 phase separation. It is designed for 24 hours continuous and smooth operation throughout the day. It is mainly composed of driving system, decanter bowl, screw conveyor inside the bowl, cover box, skid and VFD control panel.

To ensure that the separation process can take place, the solid phase must be the specifically heaviest phase and the two liquid phases must have different densities.The main difference between the 2 phase decanter and 3 phase decanter is that the 3 phase decanter not only separate the solids but also separate two phase of the liquid.

Shenzhou 3 phase decanter is widely used for oil , water, solids separation industry.

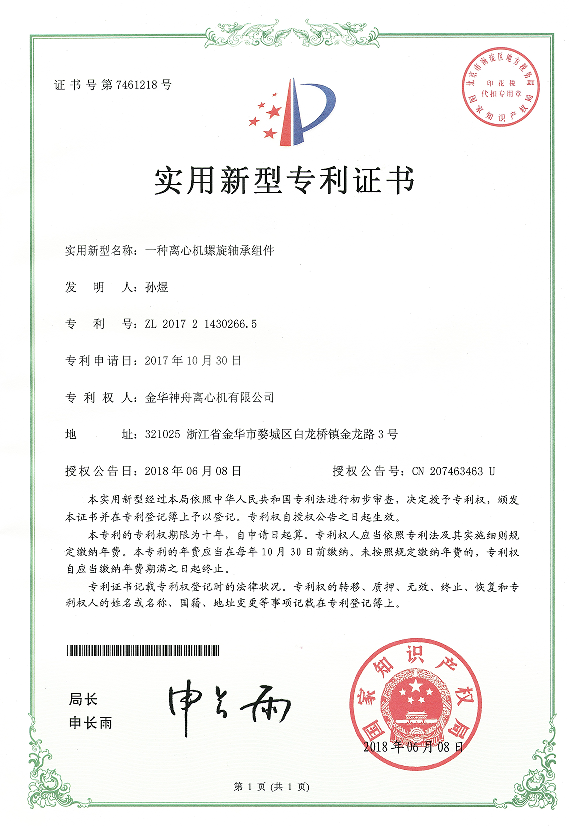

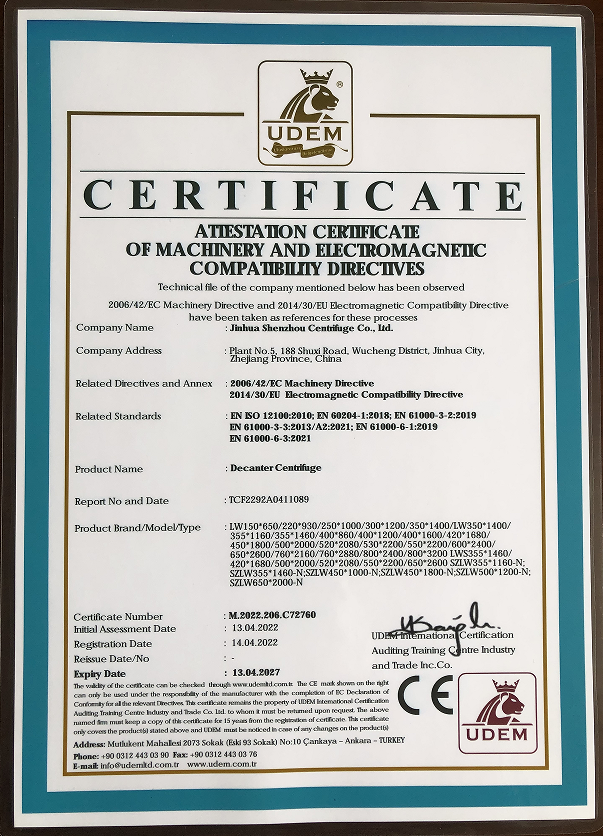

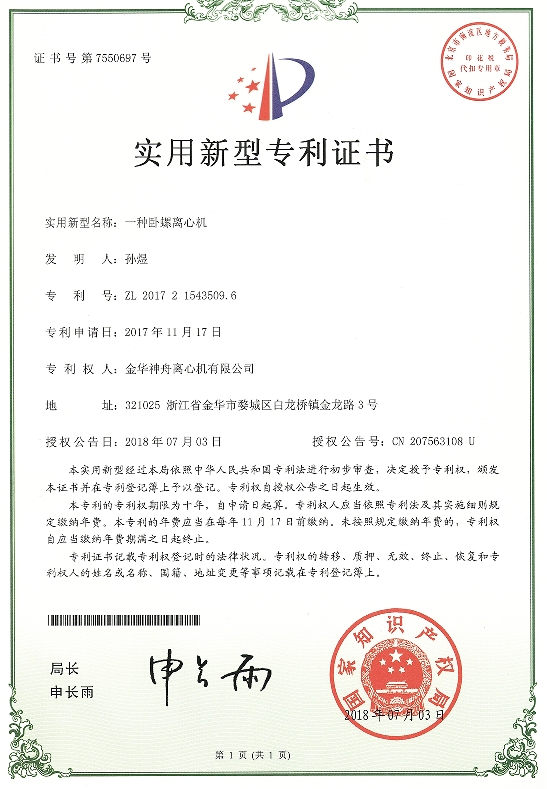

The Shenzhou 3 Phase Centrifuge is the most advanced machine for solid-liquid-liquid three-phase separation, designed for 24-hour continuous operation. Featuring a driving system, decanter bowl, screw conveyor, cover box, skid, and VFD control panel, this centrifuge ensures efficient separation with solid particles of specific weights and two different density liquid phases. With over 40 years of experience, Shenzhou's 3 phase decanter is widely used in the oil, water, and solids separation industry, offering superior quality and performance compared to competitors with CE and ISO certifications.

At Shenzhou, we are proud to present the Shenzhou 3 Phase Centrifuge, an advanced three-phase separation system designed to meet the highest industry standards. With our commitment to innovation and cutting-edge technology, we provide our customers with efficient and reliable solutions for separating oil, water, and solids. Our expertise in centrifuge technology allows us to deliver superior performance and consistent results, ensuring optimal productivity for our clients. Trust in Shenzhou for top-quality products that streamline operations and enhance efficiency in the oil and gas industry. Experience the difference with Shenzhou's advanced three-phase separation system.

Shenzhou is a leading provider of innovative separation technology, specializing in the design and manufacturing of high-performance centrifuges. Our Shenzhou 3 Phase Centrifuge is the pinnacle of our expertise, offering advanced three-phase separation for a variety of industries. Our commitment to quality, efficiency, and reliability sets us apart in the market. With a strong focus on research and development, we continuously strive to improve our products to meet the evolving needs of our customers. Trust Shenzhou for cutting-edge solutions that deliver superior results, every time. Partner with us for your separation challenges and experience the difference our technology can make.

Customer Photos

About Shenzhou

protudct information

Shenzhou 3 phase decanter centrifuge is mainly designed for Solid-liquid-liquid three-phase separation of materials.With our over 40 years of experience in the separation industry, it is the most advanced type machine for 3 phase separation. It is designed for 24 hours continuous and smooth operation throughout the day. It is mainly composed of driving system, decanter bowl, screw conveyor inside the bowl, cover box, skid and VFD control panel.

To ensure that the separation process can take place, the solid phase must be the specifically heaviest phase and the two liquid phases must have different densities.The main difference between the 2 phase decanter and 3 phase decanter is that the 3 phase decanter not only separate the solids but also separate two phase of the liquid.

Shenzhou 3 phase decanter is widely used for oil , water, solids separation industry.

3 phase decanter centrifuge working principle

The three-phase decanter centrifuge operation is based on the principle of sedimentation, that is, solid particles with specific liquid weight precipitate in a predetermined time. This principle can also be applied to two immiscible liquids with different specific gravity. When the material enters the high-speed rotating drum, the material rotates synchronously with the drum. Because of the different specific gravity, the centrifugal force is different. The solid particles with the larger specific gravity are subjected to the greatest centrifugal force, followed by the heavy phase liquid (such as water) and the light phase liquid (such as oil). So the centrifugal force is becoming less from outside to inside according to the magnitude of centrifugal force. A concentric solid layer and two liquid layers are formed. Solids are pushed out by the screw conveyor, and liquids are removed from their respective nozzles. Therefore, the application of three-phase decanter centrifuge can not only separate the solid in the material, but also separate the two-phase liquid with different specific gravity in the material, that is, Solid-liquid-liquid separation can be achieved.

Company advantages:

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1