Shenzhou Machinery specializes in producing high-speed tubular centrifuges for solids difficult to separate.The tubular centrifuge developed by our company has large separation factor and high rotating speed, so it can be used for the separation of nano particles.

GQ145 Standard tubular centrifuge from Shenzhou Group:

Product information:

Product information:

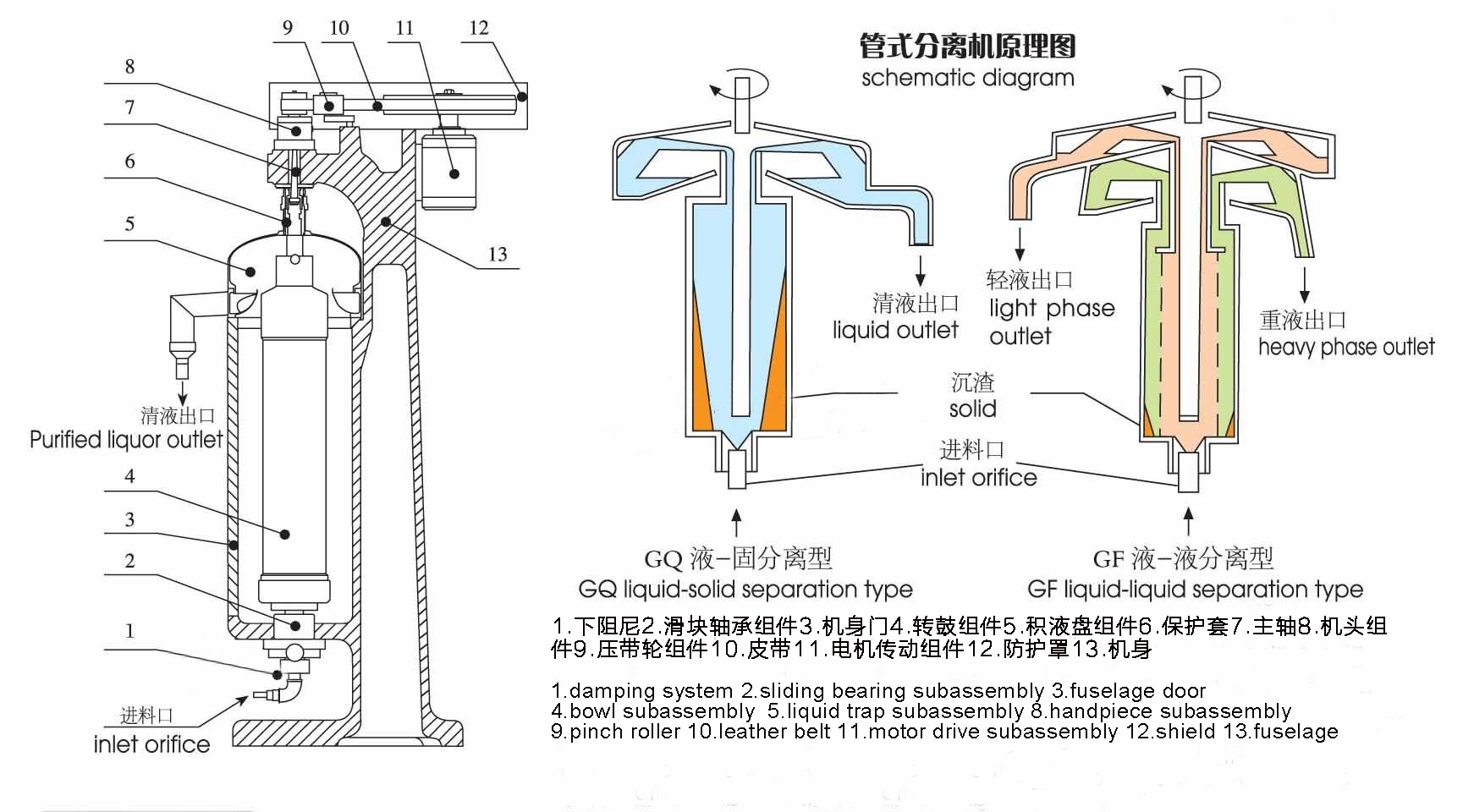

The standard GQ145 tubular centrifuge is composed of machine frame, nose assembly, recovery liquid tray assembly, tube bowl rotor assembly, sliding bearing assembly, motor assembly and other components. The motor rotates at a high speed and transmits power to the belt pulley and the main shaft on the machine nose through the transmission belt and the belt wheel. The main shaft drives the rotating bowl to rotate around its own axis at high speed, forming a strong centrifugal force field in the bowl. The feed liquid is injected into the bowl from the feed port at the bottom, and, the feed liquid is forced to separate in different layers under the strong centrifugal force. The light weight liquid is in the center of the bowl, flows to the upper part of the bowl and can be collected through the recovery liquid tray. Heavy solids are deposited on the inner wall of the bowl and are manually discharged after shutdown the machine.

High-speed tubular centrifuges are mainly used for liquid-solid separation in industries such as biopharmaceuticals, Chinese medicine clarification, bacterial recovery, blood products, plant extraction, health food, beverages, and chemical industries. High-speed tubular centrifuge is one of the most ideal equipments for material separation by centrifugal method. It is especially suitable for the extraction, concentration and clarification of materials with small liquid-solid weight difference, large viscosity, fine solid particle size and low content, and strong material corrosion.

More information:

1.This tubular centrifuge belongs to liquid-solid separation type.

2.The actual production capacity of this tubular centrifuge depends on the material characteristics and separation requirements.

3.The shell of the tubular centrifuge is made of stainless steel, and the bowl and other parts in contact with materials are made of 316L stainless steel.

4.If you need to use the centrifuge in an explosion-proof workshop, you can match an explosion-proof motor.

5.If materials that need to be separated at low temperature, customers can be optionally equipped with cooling coil, and the cold source needs to be equipped by the customer himself.

6.This tubular centrifuge can be optionally equipped with a mobile manipulators for loading and unloading the bowl.

7.This tubular centrifuge can be optionally equipped with a frequency control box.

Technical Paramter:

| Model | Bowl/drum diameter(mm) | Bowl speed | Bowl volume | Maximum centrifugal force | Maximum water capacity | Motor power | Dimensions |

| GQ145 | 145 mm | 14000 r/min | 11 L | 15900 g | 3200L/H | 3kw | 760×640×1610 mm |

More details of the machine:

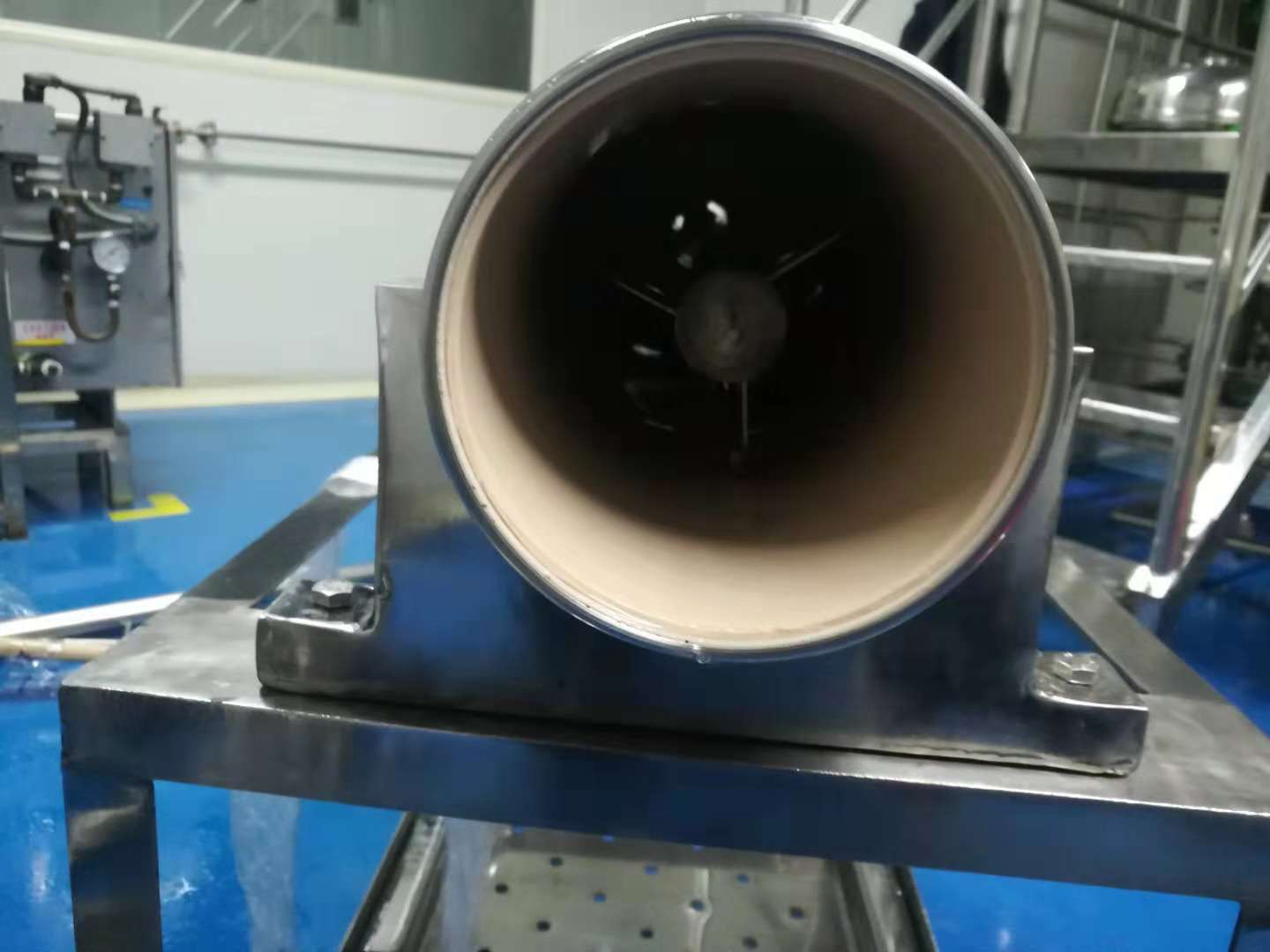

Solid in the drum Show:

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1