Professional How Does a Decanter Centrifuge Work? manufacturers

The Decanter Centrifuge

When it comes to separating solid/liquid mixes with a high solids content, decanter centrifuges are the way to go. These solid-shell scroll centrifuges or decanters, unlike chamber filter presses, run continuously. The finely distributed solid particles are separated from the suspension by strong centrifugal forces.

Decanters are useful in a wide variety of industries throughout the world. The centrifuges are optimally adapted for the specific application. Applications range from sludge dewatering to classification or wet classification to the sorting of solids.

To obtain optimum results, solid bowl decanter centrifuges must be custom designed to suit specific separation processes.

There are two phase decanter centrifuge and 3 phase decanter centrifuge in Shenzhou Group

How Do Decanter Centrifuges Actually Work?

A decanter is just a sedimentation tank wrapped around an axis. Solid particles that are heavier than liquid move to the bottom of the sedimentation tank by gravity and form a sediment (solid phase) at the bottom. A wine decanter, for example, can be thought of as a sediment vessel. The solid and liquid phases of a centrifuge are separated by centrifugal acceleration. The solid particles, which have a higher density and are hence heavier than the liquid, migrate outwards in the centrifuge’s revolving bowl due to centrifugal force. The sediment forms on the inside of the centrifuge bowl’s inner wall. The separation of solid particles from liquid is more faster and more efficient in a centrifuge because centrifugal forces of roughly 3000 g are applied instead of 1 g in a gravitational field.

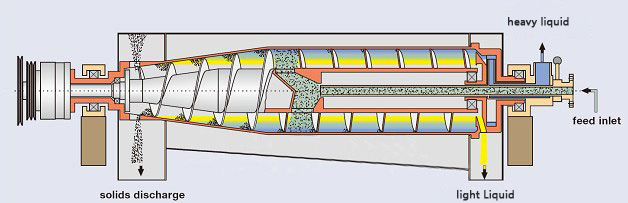

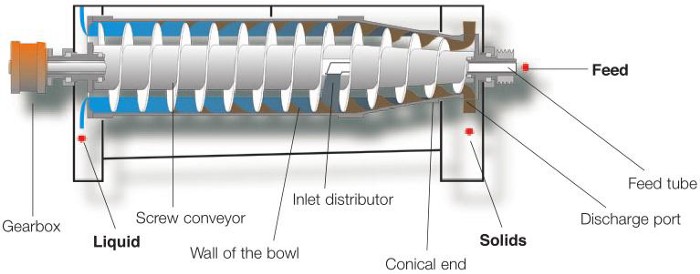

Decanter Feed Pipe Inlet

The product is fed into the decanter scroll’s inlet chamber through a centrally located feed pipe. It then travels through the distributor apertures into the decanter bowl after modest pre-acceleration.

Decanter Bowl

The cylindrical/conical decanter bowl rotates at a pre-set speed that is perfectly calibrated for the purpose. The slurry rotates at the working speed within the bowl, forming a cylindrical layer on the bowl wall. Under the influence of centrifugal force, the solids in the product settle on the inner wall of the bowl due to their higher density. The length of the cylindrical bowl section and the cone angle are chosen to fit the application’s specific needs.

Decanter Scroll

The separated solids are conveyed toward the conical end of the bowl by the decanter scroll, which rotates at a slightly different speed than the bowl. The solids’ residence period in the decanter bowl is determined by this differential speed. Cake dryness is influenced by the amount of time it spends in the oven. It may be modified by adjusting the scroll’s differential speed, resulting in appropriate separation. Scrolls are constructed differently depending on the application and activity.

Solids Discharge

Settled solids are ejected into the solids housing through ports at the conical end of the bowl and fall through the discharge chute.

Overflow

The cleared liquids (fluid phase) flow to the bowl’s cylindrical end and exit through weir plates. The pond depth (liquid layer) in the bowl is regulated by extremely precisely adjustable weir plates (overflow weirs) in these apertures. The liquid is gathered in the drain housing and expelled via gravity.

Impeller

The clarified liquid can alternatively be expelled via an impeller and discharged from the bowl under pressure in a closed system as an alternative to the overflow weir. A separate chamber pump is no longer required. The adjustable impeller, a more advanced type, allows for infinitely changeable pond depth control during the run. This allows for quick and delicate adjustments to changing conditions without shutting down the decanter centrifuge.

Types Of Decanters

There are several types of decanter centrifuges currently utilized in the industry, the most widely recognized are vertical, horizontal and conveyor centrifuges. The principle behind a decanter centrifuge is based on the theory of gravitational separation. For example, if you fill a vessel with a mixture of mud and water, over time the weight of the mud will cause it to settle down at the base of the vessel. With the mud congealed at the bottom, the water will be forced upwards, creating a clear separation between the two.

Decanter Principles

A decanter centrifuge employs the same principles of gravitational force. However, unlike the glass mixture, the process is expedited through the use of continuous rotation. In fact, rotation provides anywhere from 1000 to 4000 times the normal gravitational force, reducing the time required for separation from hours to seconds.

Rotational Separation

The concept of rotational separation is similar to rides found at amusement parks and county fairgrounds. In these rides, placing yourself at an angle allows you to overcome the gravitational forces induced by rotation. Similarly, a decanter centrifuge is essentially a bowl tube that rotates at an extremely high speed. The bowl tube is equipped with an internal conveyor which moves in the same direction but at a different velocity.

How the Decanter Process Works:

1: The slurry is brought into the centrifuge through an intake pipe and onto a conveyor.

2: Utilizing an internal feed compartment, the conveyor moves the slurry through a nozzle into the bowl.

3: The bowl rotates at high speeds to induce centrifugal forces.

4: High speed rotation separates the solid material from the liquid in a matter of seconds.

5: The conveyor delivers the solid material upwards where it is discharged through a nozzle.

6: The solid material removed, the purified liquid is released from a separate output. The ability to purify a liquid makes decanter centrifuges ideal for waste water treatment facilities. However, there are variety of industries for which such centrifuges play an important role. Similar to other decanter equipment, centrifuges are simple to install and do not require a foundation to build upon. Their efficiency saves time and materials and is an essential component for many blue collar industries

What is a Decanter Centrifuge? Horizontal Bowl centrifuges are also known as decanter centrifuges, centrifugal decanters or simply decanter machines and are primarily used for separation of liquids from appreciable amounts of solids. Decanters can separate over 50% (v/v) solids from liquids on a continuous basis. Typical industrial decanter applications include Crude Oil Tank Bottoms; Waste Oil; Industrial Wastewater; Sludge Dewatering; Fish Meal; WVO/UVO De-Sludging; Paint Sludge; Rendering etc. etc. For More Information on Decanter Centrifuge Repair Call Centrifuge World.

How does it work? A decanter centrifuge separates solids from one or two liquid phases in one single continuous process. This is done using centrifugal forces that can be well beyond 3000 times greater than gravity. When subject to such forces, the denser solid particles are pressed outwards against the rotating bowl wall, while the less dense liquid phase forms a concentric inner layer. Different dam plates are used to vary the depth of the liquid – the so-called pond – as required.

The sediment formed by the solid particles is continuously removed by the screw conveyor, which rotates at a different speed than the bowl. As a result, the solids are gradually “ploughed” out of the pond and up the conical “beach”. The centrifugal force compacts the solids and expels the surplus liquid. The dried solids then discharge from the bowl. The clarified liquid phase or phases overflow the dam plates situated at the opposite end of the bowl.

Horizontal Decanter Centrifuges Centrifuge World offers a wide variety of horizontal continuous cleaning decanter centrifuges which provide effective, low-maintenance solutions to continuous liquid clarifying and / or solids dewatering with advanced process and mechanical performance features.

Decanter centrifuges are extremely versatile and capable of adapting to varying throughput and process and material types. The machines are easy to adjust, require little operator attention, are relatively quiet and feature a small footprint

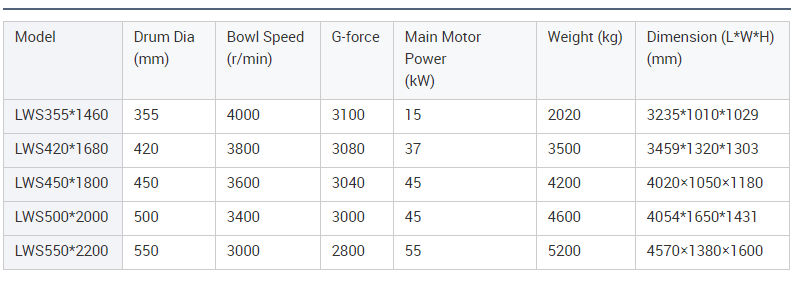

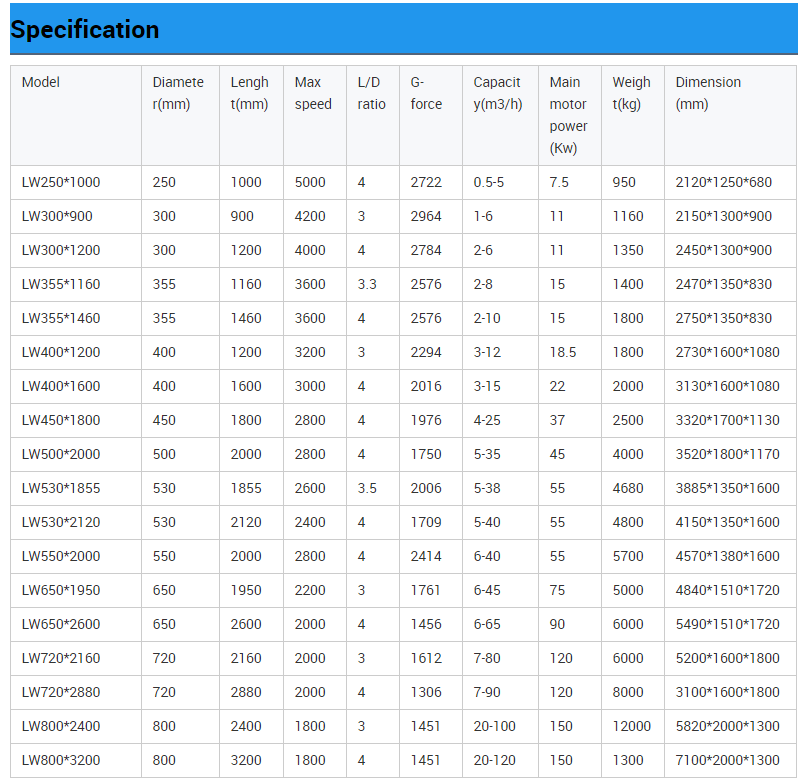

Two phase decanter centrifuge paratmeter:

Three phase decanter centrifuge paratmeter: