LW900 Decanter centrifuge for sludge thickening

Decanters for Sludge Dewatering Processing

Sludge centrifuge is professional industrial separation equipment for sludge dehydration treatment. The central part is composed of a cylindrical bowl. When the equipment is working, the bowl rotates at high speed to separate the wastewater liquid from the solid and discharge the liquid and solid substances separately through the discharge port. The equipment has an automatic control system and can work continuously without interruption. Which can significantly improve the efficiency of sludge treatment.

SEPARATION Decanters for Sludge Dewatering Processing

SHENZHOU sludge centrifuge is professional industrial separation equipment for sludge dehydration treatment. The central part is composed of a cylindrical bowl. When the equipment is working, the bowl rotates at high speed to separate the wastewater liquid from the solid and discharge the liquid and solid substances separately through the discharge port. The equipment has an automatic control system and can work continuously without interruption. Which can significantly improve the efficiency of sludge treatment.

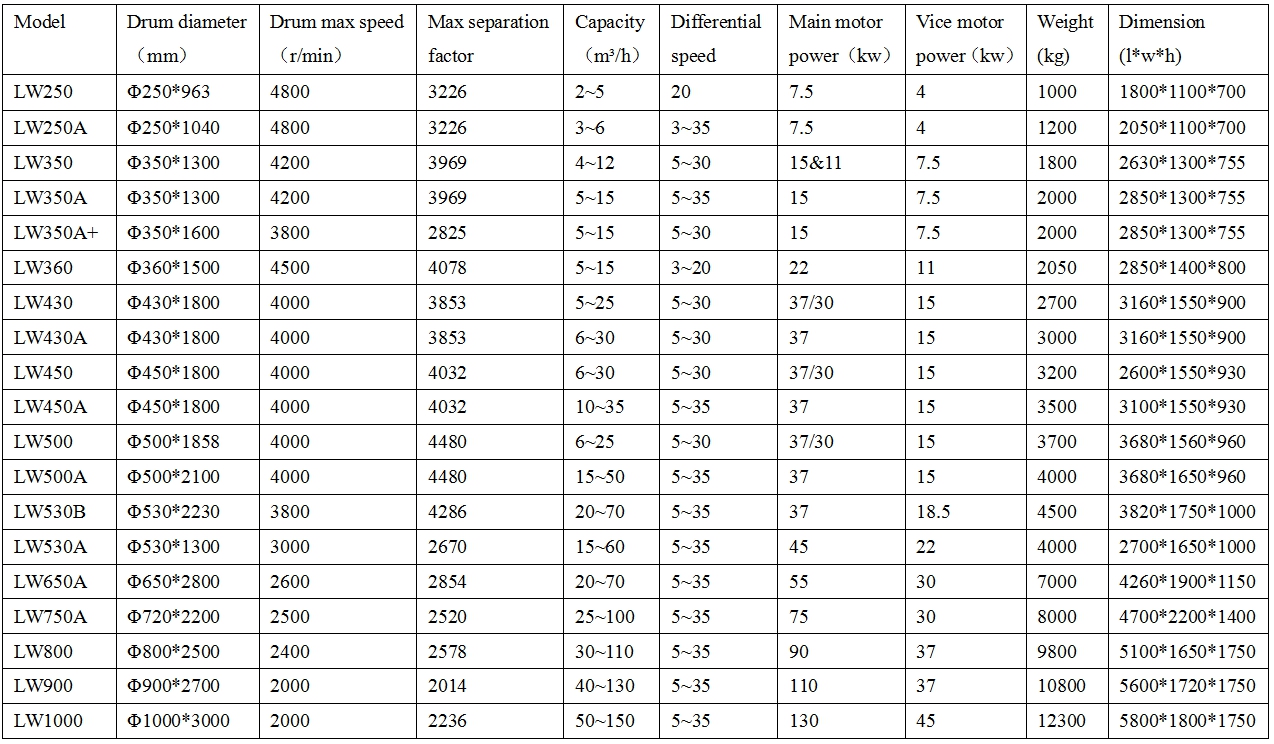

This is horizontal spiral discharging settling centrifuge, it is continuous automatic separator.the main machine has a column-cone bowl, spiral stoker,differential system, bearing seat, base, cover, main motor, vice motor, and electric control chamber. With the high speed rotating of bowl, strong centrifugal force occurs, it makes the solid liquid separation continuously in 24 hours a day.it has been widely used in the pharmaceutical,food industry,plant extraction, chemical solid dewatering, waste sludge treatment and so many other fields.

Features

1. Frequency inverter drive system, realize differential speed stepless regulation and energy return.

2. Spiral stoker blades: Surfacing welding tungsten carbide grinding.

3. Drum cone cylinder material outlet: Replaceable wear resistant, corrosion resistant ceramic alloy bushing.

4. Main bearing: Sweden NSK

5. Main sealing parts: Taiwan SOG, material is Nitrile butadiene rubber

6. Electrical protection: overload, phase loss, torque protection

7. Main and vice inverter use common DC bus, vice motor’s function is generating electricity ( save electricity)

8. PLC remote control(Optional)