Separator has taken a further step in the field of brewing beer. Whereas separators and decanters have been used for a long time in the production of beer, the latest process represents a further milestone in filtration technology: the beer separator and membrane are combined, the entire filtration process flows continuously, with maximum yield and a simple method of changing types. The environment is protected and process costs are reduced. Anyhow, disc separators and decanter centrifuges play a key role in the manufacture of beer. In the decisive steps of the brewing process, they ensure economical operation and a high quality of beer.

Beer can be produced on any scale from small home brews, to craft beer micro-breweries, and finally large industrial scale. However, the brewing process is ultimately very similar on each scale as below:

Outline dimension(L*W*H)

━ Beer Recovery from Tank Bottoms

━ Clarification of Beer before Kieselguhr Filtration

━ Cold Wort Separation

━ Green Beer Clarification with Addition of

━ Yeast/Tank Bottoms

━ Green Beer Separation

━ Hot Wort Separation

━ Manufacture of Non-Alcoholic Beer

━ Trub Wort Separation

━ Turbidity Adjustment with Separators

In a brewery centrifuge, which may also be called a beer separator or a decanter centrifuge, these same principles are applied to a liquid-wort or beer. The liquid is laden with various types of suspended particulate, including yeast, trub, and hop residue, each with a different density. When a centrifuge spins the liquid within a round bowl, at a given rotation speed, eventually the heavier components of the liquid, notably trub and yeast, because they experience greater centrifugal forces, will move closer to the bowl’s outer wall. Meanwhile, the lightest components, including water and alcohol, will stay closer to the center axis of the rotation bowl. This type of centrifugal separation is aided further by the fact that the circumference of the circle traveled by the liquid closest to the center is much smaller than the one traveled by the particles along the outer wall. This even further reinforces the separation of particles in the liquid according to their density. In terms of physics, the power of the centrifugal forces is governed by an equation called Stokes’ law, and centrifuges in a brewery are constructed to generate truly enormous rotational forces that may be several thousand times the size of the earth’s gravitational forces. See stokes’ law. Such disc beer separator or decanter centrifuge also allow for the draining of the clear, separated liquid from the rotation bowl, while removing the undissolved particles out of the bowl. This is the principle of a functioning centrifuge in practice. Centrifuges in the brewery are employed in several ways. A wort centrifuge can separate hot trub from clear wort even more efficiently than a whirlpool, which is actually a type of low-tech centrifuge. A beer centrifuge employed before packaging can reduce the beer’s turbidity by separating many or most of the yeast cells from the clear beer. This is particularly useful if the beer is to be packaged unfiltered, but the yeast does not flocculate sufficiently to the bottom of the fermenter. It is possible to link the centrifuge to an optical sensor that measures the turbidity of the beer; properly used, this setup can be used to adjust haze or yeast cell counts in the final package. Likewise, a beer separator can remove some of the yeast between the end of primary fermentation and the beginning of secondary fermentation or before lagering. If the brewery uses fining agents, these, too, can be removed via centrifuge. Another favorite location for the use of centrifuges is right before an in-line filter. Because the centrifuge removes the bulk of the particulate, the filter medium can perform its function for much longer intervals before it needs to be serviced. A completely different purpose of a centrifuge is beer reclamation. When excess or spent yeast slurry is purged out of the bottom of a fermenter, the liquid part of the slurry is of course perfectly drinkable beer. Some breweries consider it worthwhile to centrifuge the slurry and introduce the reclaimed beer back into the beer flow. Finally, beer can be centrifuged to remove any residual cold break right before packaging. This eliminates, among other substances, some of the protein-type of materials that are directly and indirectly involved in haze formation as well as beer oxidation.

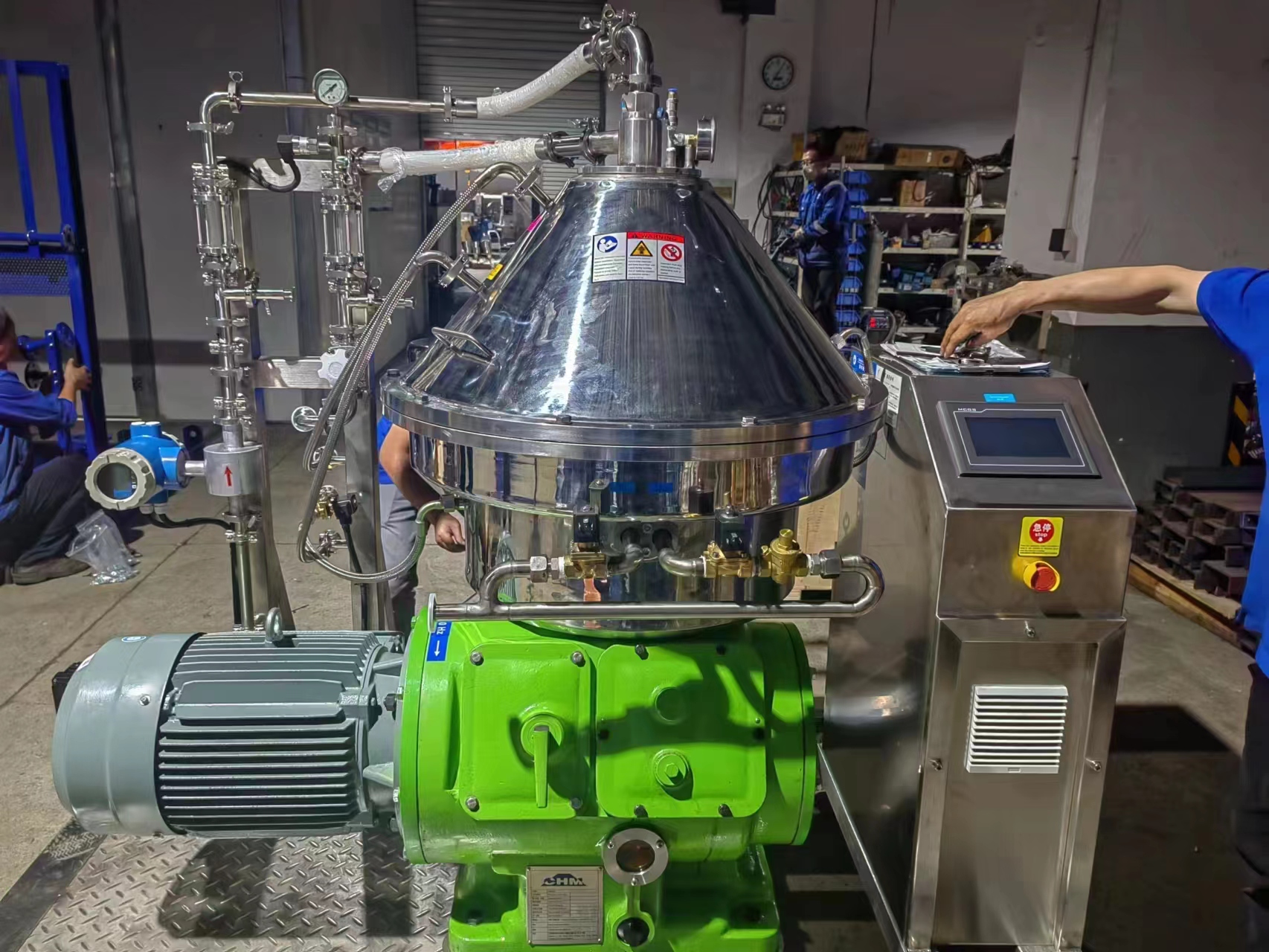

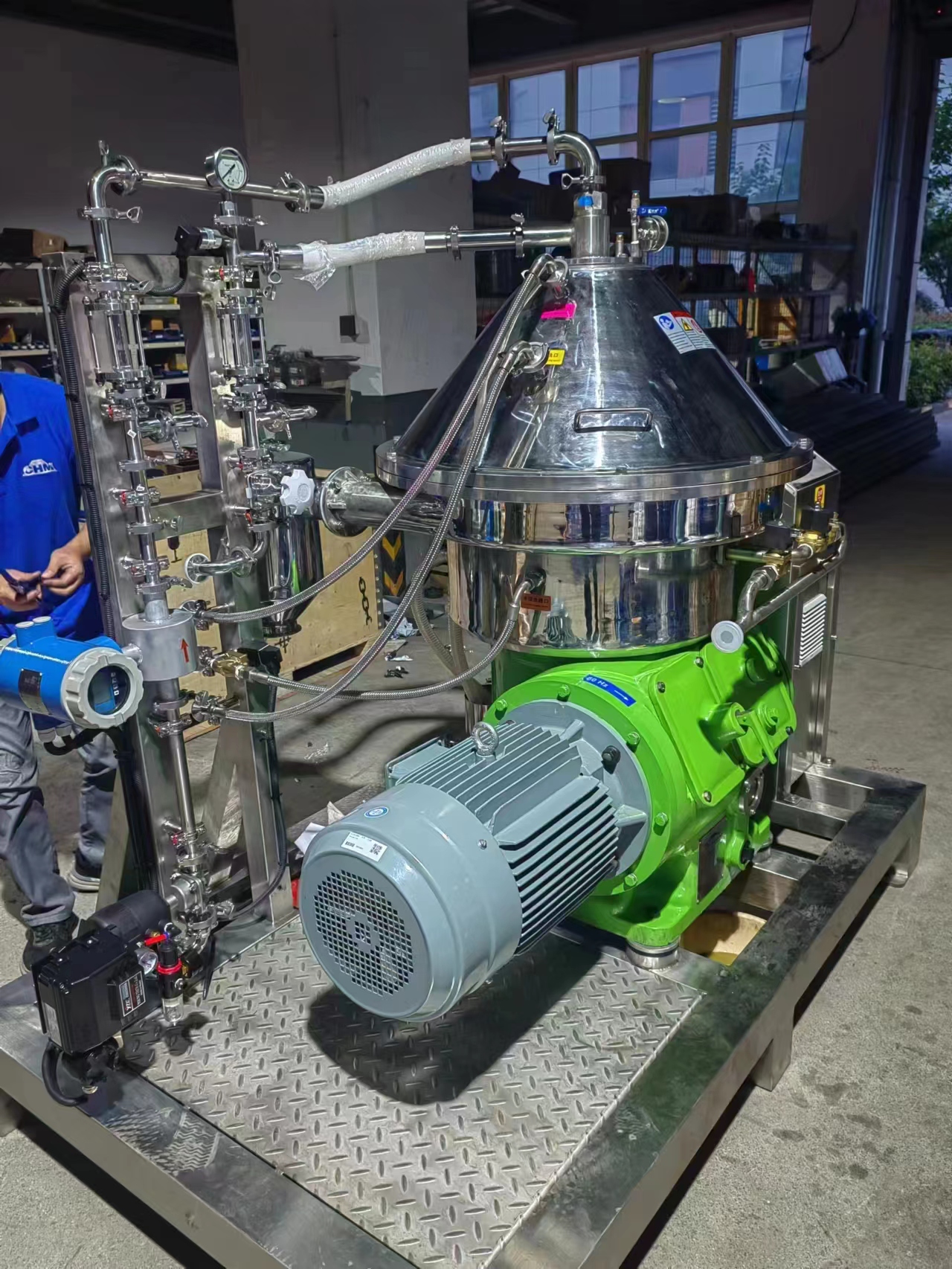

Main technical parameter Of disc centrifuge:

Model number | DBQ470 |

Capacity | ~ 1000L-10000L/h(depend on solid contentl) |

Disc diameter | 450mm |

Slag volume | 5.7L |

Disc half cone Angle | 40° |

Number of discs(Piece) | 90+/5 |

Rod form | Oblique form |

Disc clearance | 0.45mm |

Drum speed | 5300r/min |

separation factor | 8000 |

Design discharge pressure Mpa | 0.2~0.3 |

Feeding way | pressure-feed |

Method of discharge of solids | Automatic slag removal |

Operating water operation mode | Intermittent discharge |

Noise | ≤ 80dBA |

Shock Absorption System | Damping damper |

Power | 15kw |

Motor speed | 2850r/min |

Phase/frequency/voltage | 3P/50~60Hz/380V |

Start way | Friction starts |

Braking way | Free shutdown |

downtime | About 10 min (natural shutdown about 35 min) |

Net weight : | About 1500Kg |

Outline dimension(L*W*H) | 1500*1400*1600 |

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1