Intro to LWS355 Three phase decanter for waste oil separation Shenzhou

A three-phase decanter is a centrifugal separator that separates two immiscible liquids while simultaneously separating the solids. The liquid phases discharge through discrete outlets, and the solids eject out of the decanter’s sludge nozzles.

A three-phase decanter is a centrifugal separator that separates two immiscible liquids while simultaneously separating the solids. The liquid phases discharge through discrete outlets, and the solids eject out of the decanter’s sludge nozzles.

Table of Contents

Working Principle

Types

Process Optimization

Benefits

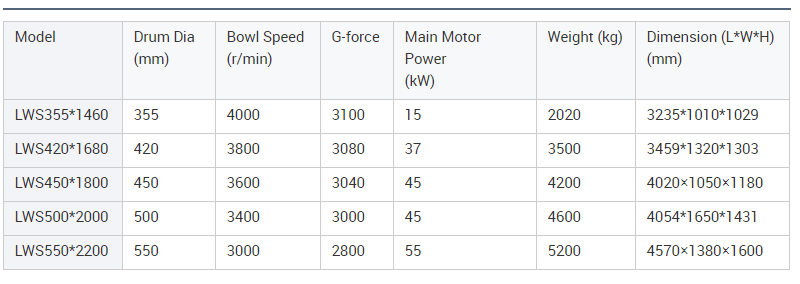

Specifications

Application

Working Principle

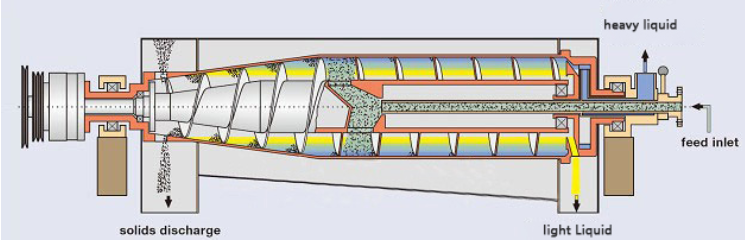

Three Phase Decanter Diagram

The 3-phase separation occurs in the horizontally rotating bowl of the decanter centrifuge. A fixed inlet tube feeds the slurry into the bowl, where the fluids are gently accelerated.

The high centrifugal force causes the heavier solids to accumulate on the bowl wall. The screw conveyor rotates within the bowl at a differential speed to the bowl. The relative rotation between the bowl and the screw pushed the solids to the bowl's conical section.

The centrifugal force drains the liquid from the solids as they move up the conical bowl wall. The conveyor pushes the dry solids through the sludge outlet ports. The ejected solids fall out of the casing vessel.

The entire cylindrical bowl section is the separation surface. The heavy and light liquid phases exit the bowl into individual chambers for each liquid phase in the decanter vessel.

Process Optimization

The three-phase decanter centrifuge can adapt to specific process requirements by:

- Changing the bowl rotational speed to exert the best G-force for separation.

- Adjust the scroll differential rotation to balance liquid clarity and sludge handling capacity.

- Calibrate the pond depth to adjust liquid clarity versus solid dryness.

- Interphase adjustment between the heavy and light liquid phases.

- Changing the feed flow rate. These 3-phase decanters can handle a wide range of feed rates.

Benefits

The benefits of three-phase decanters include:

- The simultaneous separation of two liquids and solids

- The ability to handle a wide range of solids concentrations

- The adjustment of the centrifuge during the process

- Low operating cost for high processing volume

- Compact size to process capacity ratio

- Reduced operator exposure to process fluids by sealed design

- Long service life due to absence of replaceable media

Technical Paramter of three phase decanter from Shenzhou Group you can contact us freely!

Customers from other countries visited Shenzhou Group: