Analysis of the Structure of Tubular Centrifuge

There are two models of tubular centrifuges.

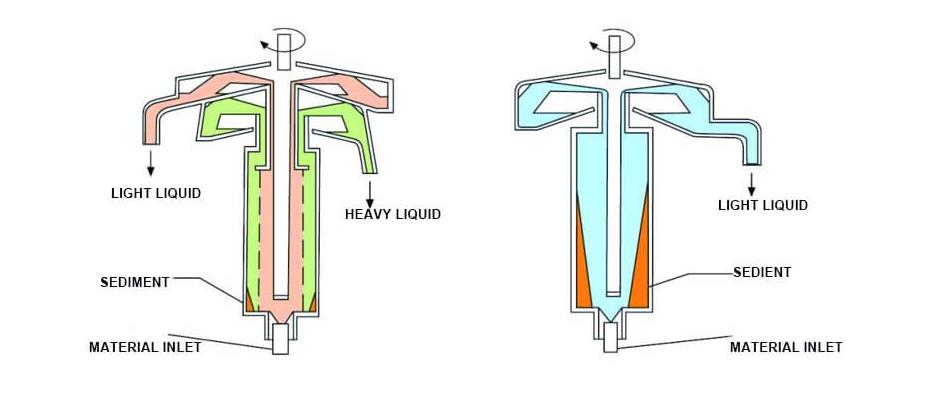

GF and GQ are two types GF is mainly used for liquid-liquid or liquid-liquid solid separation with small amounts of impurities.

GQ is mainly used for liquid-solid separation.

Due to the manual unloading required by the tubular centrifuge, it is best not to exceed a solid content of 2%. If the solid content is too high, frequent shutdowns will have a certain impact on the service life of the tubular centrifuge!

As the largest manufacturer of tubular centrifuges in China, today we will mainly analyze the swinging tubular centrifuges.

The external structure of a tubular centrifuge is enclosed, meaning that the body is enclosed. The drum needs to be removed from above the body.

Secondly, there is a door opening structure, and when taking out the drum, simply open the body door.

In addition, our newly developed swinging tube centrifuge greatly facilitates the retrieval of the drum. It saves labor and operates very safely.

On the other hand, the damping device included in the shaking tube centrifuge equipment produced by Shenzhou improves the safety factor of equipment operation, making it the company's central product and patented product. Therefore, it can achieve anti-corrosion and explosion-proof effects during operation; The rotatable body is equipped with a mobile operating platform, which can rotate the body to the horizontal and directly pull the drum onto the mobile operating platform, facilitating cleaning and handling by staff, and dealing with most safety hazards during the separation process.

Based on our market research, it has been found that the shaking tube centrifuge equipment has become the preferred equipment for many production enterprises today. The equipment itself has low cost, but the production power is high. Therefore, we recommend that enterprises with demand can choose shaking tube centrifuge equipment to separate materials, which is not only cost-effective, but also has high practicality.