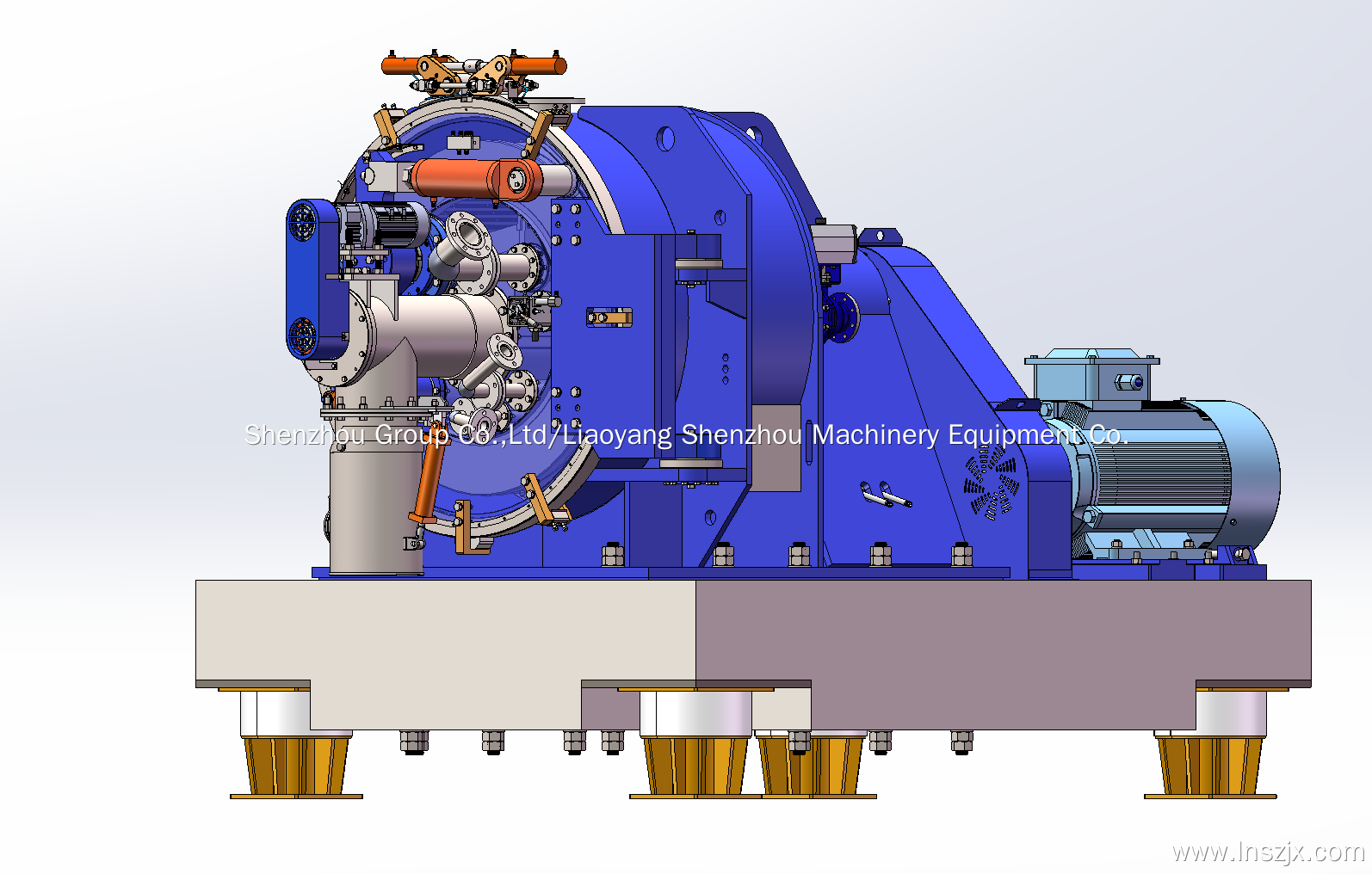

Horizontal Centrifuge As Siphon Peeler Centrifuges For Solid Liquid Separation,This machine is controlled by PLC and regulates speed by frequency convertor, braking system applies dynamic braking and regenerative braking, the whole separation process is automatic circulative process and manual operation mode is applicable to be changed over from automatic operation mode.

Application

GKH Series automatic siphon centrifuge is a solid-liquid separation equipment which adopts continuous operation and intermittent discharging.Its production capacity and separation effect is better than GK(F) centrifuge.

Automatic Horizontal Scraper Peeler Centrifuge Starch Machine For Separation,GK Peeler Centrifuge Series automatic siphon centrifuge is more suitable for separating such product as small solid phase granularity and which is hard to be separated.It is widely used in pharmaceutical, Chemical and foodstuff industry (e.g. starch, calcium phosphate, Sodum bicarbonate)

Structure Sketch Map

Working Principle

1.Except centrifuge force like the other common centrifuge siphon centrifuge also has a kind of siphon draught force similar to vacuum pipe.

2.When the centrifuge is of no load,the counter-pulse pipe feeds the liquid to siphon chamber and the liquid is forced to the clearance through the via hole on the drum of siphon chamber.Then air of siphon pipe is eliminated and a layer of liquid forms on the filtering media,so as to make the feeding more even.

3.Then feeding starts,the siphon pip rotates to a certain position and it turns to a lower position required after a certain period.When the feeding is finished,the siphon pipe turns to the lowest position(Max diameter place of siphon chamber).

4.After the suspension liquid comes into the drum,solid products are left on the filter cloth while the liquid is forced to go through the filter cloth and internal drum and collected in the clearance between internal and external drum,then it flows into the siphon chamber through drum and via hole.

5.Next the liquid will be draught by siphon pipe and the deposited solid will be dewatered and scraped by scraper which is driven by oil cylinder. And then the solid falls out through hopper.

6.When discharging is finished,centrifuge begins to clean the mesh.The siphon centrifuge not only washes the filter cloth in the drum,but also feeds the washing water to siphon chamber.By controlling the upper and lower rotation of siphon pipe,liquid can counter-pulse wash the filter mesh from the internal drum.

7.When the washing is finished,carry out the next circulative processing cycle.

Main Characteristics

1.Comparing with common horizontal centrifuges with the same specification,the production capacity can be raised by 40% to 60% and the moisture content of filter cake is lower.

2.Different filter speed can be realized during different process as feeding separation filtering,washing and dehydration.

3.The centrifuge will be always under best working condition and the equipment operates stably and the vibration and noise are rather low.

4.When the scraper is finished,the regenerate liquid will be fed from the siphon feeding pipe to regenerate and resuspension the filter cake,bake flush and remove the left filter cake.

5.The automatic residual cakes removing device is optional (have owned the national patent).

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1