Shenzhou - Upgraded SZ-A02 Pneumatic Filling Machine Small Quantitative Cosmetic Cream Paste Filling Machine Filling&Packing Machine

Our employees are well trained to be skilled at applying technology to the Upgraded SZ-A02 Pneumatic Filling Machine Small Quantitative Cosmetic Cream Paste Filling Machine manufacturing process. It has been continually proved that it can be widely used in the application field(s) of Filling Machines.

5.0

Customization:

Customized logo (Min. Order: 1 Sets),Customized packaging (Min. Order: 1 Sets),Graphic customization (Min. Order: 1 Sets)

shipping:

Support Sea freight · Land freight

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

For manufacturing Upgraded SZ-A02 Pneumatic Filling Machine Small Quantitative Cosmetic Cream Paste Filling Machine requiring flexible craftsmanship and high-end technologies.The product is suitable for a wide range of industries like Filling Machines. Modern technologies innovate means are adopted for the flawless manufacturing of Upgraded SZ-A02 Pneumatic Filling Machine Small Quantitative Cosmetic Cream Paste Filling Machine.So far, the application areas of the product have been expanded to the Filling Machines. Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd adhere to the corporate philosophy of 'people orientation' and always advocate honesty, innovation, and fairness. We hope to occupy an important position in the industry and become one of the most leading brands in the future.

| Type: | Filling Machine | Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company |

| Showroom Location: | None | Condition: | New |

| Application: | Food, Commodity, Chemical, Medical | Packaging Type: | Bottles, Stand-up Pouch, Bags, Pouch, Other |

| Packaging Material: | Plastic, Paper, Metal, Glass, Other | Automatic Grade: | Other |

| Driven Type: | Manual | Voltage: | 220V/50-60HZ |

| Place of Origin: | China | Brand Name: | SHENZHOU |

| Dimension(L*W*H): | 850*500*1400mm | Weight: | 13 KG |

| Warranty: | 1 Year | Key Selling Points: | Easy to Operate |

| Machinery Capacity: | 2000BPH | Filling Material: | Beer, Other, Milk, Water, Oil, Juice |

| Filling Accuracy: | ≤±1% | Marketing Type: | Hot Product 2021 |

| Machinery Test Report: | Not Available | Video outgoing-inspection: | Provided |

| Warranty of core components: | 1 Year | Core Components: | Motor |

| Material: | Stainless Steel 304 | Filling Speed: | 10-20 bottles/min |

| Filling weight: | 5-50ml | Product name: | Manual Filling Machine |

Product Description

Upgraded SZ-A02 Pneumatic Filling Machine Small Quantitative Cosmetic Cream Paste Filling Machine

Features & Details

* [EFFICIENT PNEUMATIC FILLING]- The liquid and paste filling machine is driven by pneumatic power. Filling speed: 20-60 times/minute. Filling volume: 5-50ml(adjustable). Give you an efficient and accurate filling. Needs to work with an air

compressor. Please prepare by yourself.

* [DURABLE CONSTRUCTION] - This paste liquid filling machine comes with a food-grade stainless steel hopper with a large capacity of 22lbs/10kg. Thickened and solid base keeps the machine sturdy. Resistant to corrosion, rust, alkali, and acid.

* [REASONABLE DESIGN]- Designed with a high-quality anti-drip filling nozzle, made of premium steel, this bottle filling machine features accurate filling. Filling volume and speed can be adjusted. The oil/water separator used to connect an air compressor extends the service life.

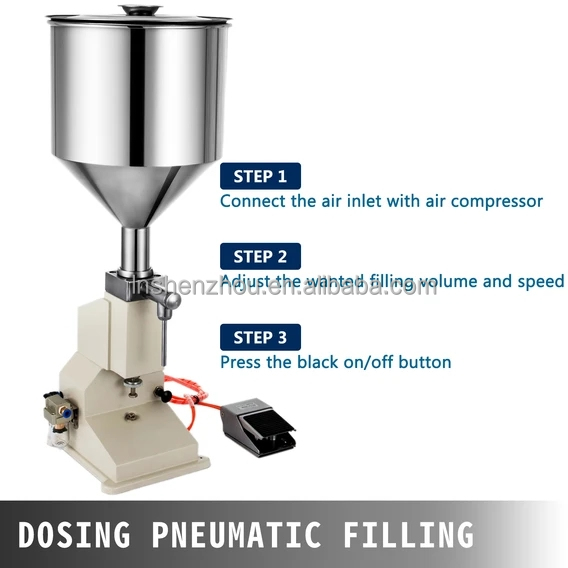

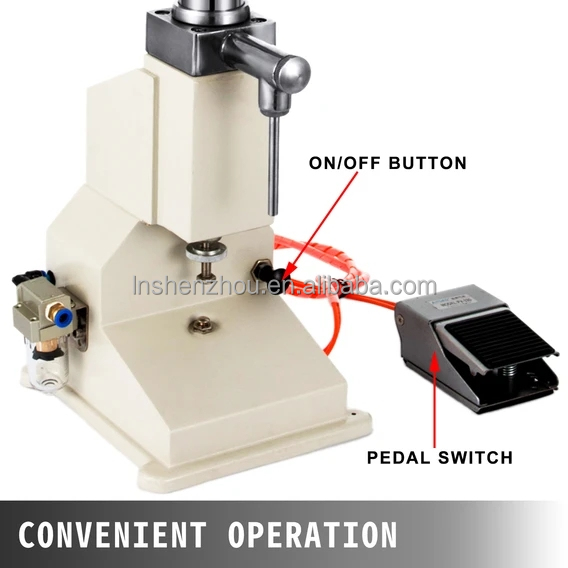

* [EASY TO OPERATE]- Connect the air compressor, adjust the filling volume and speed, then press the black on/off button, thecream filling machine is going to start work. Use the pedal switch to control and finish the filling.

* [VARIOUS APPLICATION]- This pneumatic filling machine is suitable for filling liquid, oil, shampoo, liquid substance, paste liquid filling machine function, widely used in food & beverage, cosmetics, and pesticides and other special industries.

Notice

The machine doesn't contain an air compressor. Please prepare a 500W air compressor by yourself. And a 0.8 mm hose is also needed to connect the pneumatic filling machine and air compressor.

* [EFFICIENT PNEUMATIC FILLING]- The liquid and paste filling machine is driven by pneumatic power. Filling speed: 20-60 times/minute. Filling volume: 5-50ml(adjustable). Give you an efficient and accurate filling. Needs to work with an air

compressor. Please prepare by yourself.

* [DURABLE CONSTRUCTION] - This paste liquid filling machine comes with a food-grade stainless steel hopper with a large capacity of 22lbs/10kg. Thickened and solid base keeps the machine sturdy. Resistant to corrosion, rust, alkali, and acid.

* [REASONABLE DESIGN]- Designed with a high-quality anti-drip filling nozzle, made of premium steel, this bottle filling machine features accurate filling. Filling volume and speed can be adjusted. The oil/water separator used to connect an air compressor extends the service life.

* [EASY TO OPERATE]- Connect the air compressor, adjust the filling volume and speed, then press the black on/off button, thecream filling machine is going to start work. Use the pedal switch to control and finish the filling.

* [VARIOUS APPLICATION]- This pneumatic filling machine is suitable for filling liquid, oil, shampoo, liquid substance, paste liquid filling machine function, widely used in food & beverage, cosmetics, and pesticides and other special industries.

Notice

The machine doesn't contain an air compressor. Please prepare a 500W air compressor by yourself. And a 0.8 mm hose is also needed to connect the pneumatic filling machine and air compressor.

Dosing Pneumatic Filling

This liquid filling machine is driven by pneumatic power. Filling speed: 20-60 times/minute. Filling volume: 5-50ml(adjustable). Filling accuracy (+/- 1%). Filling volume can be accurately controlled.

This liquid filling machine is driven by pneumatic power. Filling speed: 20-60 times/minute. Filling volume: 5-50ml(adjustable). Filling accuracy (+/- 1%). Filling volume can be accurately controlled.

Durable Hopper & Base

All parts of the pneumatic liquid filler that touch the material being filled are made of food-grade stainless steel, including

the hopper with a capacity of 10 kg. The solid base keeps sturdy. Easy to maintain.

All parts of the pneumatic liquid filler that touch the material being filled are made of food-grade stainless steel, including

the hopper with a capacity of 10 kg. The solid base keeps sturdy. Easy to maintain.

Anti-drip Filling Nozzle

A high-quality anti-drip filling nozzle, made of premium steel, is not easily plugged, ensuring this automatic liquid filling

machine an accurate and efficient filling. Stable, smooth, and durable.

A high-quality anti-drip filling nozzle, made of premium steel, is not easily plugged, ensuring this automatic liquid filling

machine an accurate and efficient filling. Stable, smooth, and durable.

Manual filling machine

1.It is suitable for filling liquid and paste with good liquidity.

2. It is of wide working scope,applicable for medicine,daily chemical,food,pesticide and other industries.

3. Can fill beverage ,fluid food,lubricating oil,shampoo and other liquid paste material(without particulate)

4. All parts in contact with the filling object are made of stainless steel and food grade material.

5. The machine is simple to operate.

6. It has anti-drip function.

They are suitable to fill water, beverage, oil, ink, lotion, shampoo, sauce, jam, gel, cream, etc in the field of cosmetic,

drinks, chemical, medical, food, etc.

1.It is suitable for filling liquid and paste with good liquidity.

2. It is of wide working scope,applicable for medicine,daily chemical,food,pesticide and other industries.

3. Can fill beverage ,fluid food,lubricating oil,shampoo and other liquid paste material(without particulate)

4. All parts in contact with the filling object are made of stainless steel and food grade material.

5. The machine is simple to operate.

6. It has anti-drip function.

They are suitable to fill water, beverage, oil, ink, lotion, shampoo, sauce, jam, gel, cream, etc in the field of cosmetic,

drinks, chemical, medical, food, etc.

Adjustable Filling Volume

With the filling volume regulator knob, quantitative discharging, filling rate, and filling speed can be controlled. Turn the

regulator knob clockwise or anti-clockwise to find your needed filling condition.

With the filling volume regulator knob, quantitative discharging, filling rate, and filling speed can be controlled. Turn the

regulator knob clockwise or anti-clockwise to find your needed filling condition.

Convenient Operation

After you connect the air compressor, adjust the filling condition, don't forget to press the on/off button to turn on the

machine, then use the pedal switch to control and finish the filling. Very convenient.

After you connect the air compressor, adjust the filling condition, don't forget to press the on/off button to turn on the

machine, then use the pedal switch to control and finish the filling. Very convenient.

Specification

name | Manual filling machine | Filling Range | 5-50 ml |

Material of machine | Stainless steel 304 | Capacity of Hopper | 10 kg |

Net weight | 11 kg | Gross weight | 12kg |

Machine size | 270x270x700 mm | Packing size | 310×310×740 mm |

Main Features

1) The machine is simple and reasonable structure, easy manual operation

2) There filling quantity adjusting device knob, can quantitative discharging, filling volume and filling speed can be controlled manually

3) Material contact parts are made of 304L stainless steel, suitable for use under acid medium,with food, medicine and production hygiene requirements.

4) The hopper capacity of 10L, users may need to be set on the filling volume.

1) The machine is simple and reasonable structure, easy manual operation

2) There filling quantity adjusting device knob, can quantitative discharging, filling volume and filling speed can be controlled manually

3) Material contact parts are made of 304L stainless steel, suitable for use under acid medium,with food, medicine and production hygiene requirements.

4) The hopper capacity of 10L, users may need to be set on the filling volume.

Details Images

Packing & Delivery

FAQ

1. who are we?

We are based in Liaoning, China, start from 2015,sell to Northern Europe(20.00%),South America(10.00%),Southern

Europe(8.00%),Eastern Asia(8.00%),Eastern Europe(8.00%),Oceania(7.00%),Central America(6.00%),Mid East(6.00%),Africa(5.00%),North

America(5.00%),Southeast Asia(5.00%),Western Europe(5.00%),South Asia(4.00%),Domestic Market(3.00%). There are total about 101-200

people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

decanter centrifuge,disc centrifuge,tubular centrifuge,tripod centrifuge,starch separator

4. why should you buy from us not from other suppliers?

Our company specially manufacturing decanter centrifuge,disc centrifuge ,tubular centrifuge and other kinds of machines about 20

years in China.And we can according to your requirements to design the machine to meet your requirements.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Portuguese,French,Russian,Korean,Italian

We are based in Liaoning, China, start from 2015,sell to Northern Europe(20.00%),South America(10.00%),Southern

Europe(8.00%),Eastern Asia(8.00%),Eastern Europe(8.00%),Oceania(7.00%),Central America(6.00%),Mid East(6.00%),Africa(5.00%),North

America(5.00%),Southeast Asia(5.00%),Western Europe(5.00%),South Asia(4.00%),Domestic Market(3.00%). There are total about 101-200

people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

decanter centrifuge,disc centrifuge,tubular centrifuge,tripod centrifuge,starch separator

4. why should you buy from us not from other suppliers?

Our company specially manufacturing decanter centrifuge,disc centrifuge ,tubular centrifuge and other kinds of machines about 20

years in China.And we can according to your requirements to design the machine to meet your requirements.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Portuguese,French,Russian,Korean,Italian

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

GET IN TOUCH WITH Us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Copyright © 2025 Shenzhou Machinery is a core subsidiary of Shenzhou Group | Sitemap