Industrial Disc Stack Centrifuge For Algae concentration

Industrial Disc centrifuge is suitable for the concentration of algae products such as Chlorella vulgaris, red algae, red algae, etc

Disc Stack Centrifuge For Algae Concentration

The disc stack centrifuge stands as a high-efficiency core equipment for algae concentration, engineered to address the key challenges of separating microalgae (such as chlorella and spirulina) from culture media across food, biofuel, pharmaceutical, and cosmetics industries. Leveraging centrifugal forces up to 12,000 g—thousands of times stronger than gravity—it enables rapid and precise solid-liquid separation, outperforming conventional settling or filtration methods.

Its stacked conical disc design dramatically expands the effective separation area, accelerating algae particle sedimentation and ensuring continuous processing of 1,000 to over 10,000 liters per hour, depending on the model. The fully automatic PLC control system, paired with self-cleaning bowl technology, allows for unattended operation and periodic discharge of creamy or paste-like algae concentrate, while preserving the integrity of algae cells. Constructed with food-grade 304/316L stainless steel, it meets GMP standards and features CIP/SIP functions for online sterilization and cleaning, ensuring corrosion resistance even for saltwater algae cultivation.

Algae concentration equipment employs three core separation methodologies—centrifugation (including disc stack and solid bowl configurations), specialized filtration, and flocculation—to effectively separate algae biomass from aqueous culture media. The end product is a dense biomass paste or slurry primed for downstream processing.

This algae concentration equipment delivers dual advantages: it achieves algae concentrate with up to 25% dry substance content to lower subsequent processing costs, and reduces energy consumption by up to 75% compared to traditional harvesting methods. Available in two-phase and three-phase separation models, it adapts to small-to-medium facilities (single-stage process) and large-scale industrial operations (two-stage process with pre-concentration), making it a versatile and cost-effective solution for algae concentration needs.

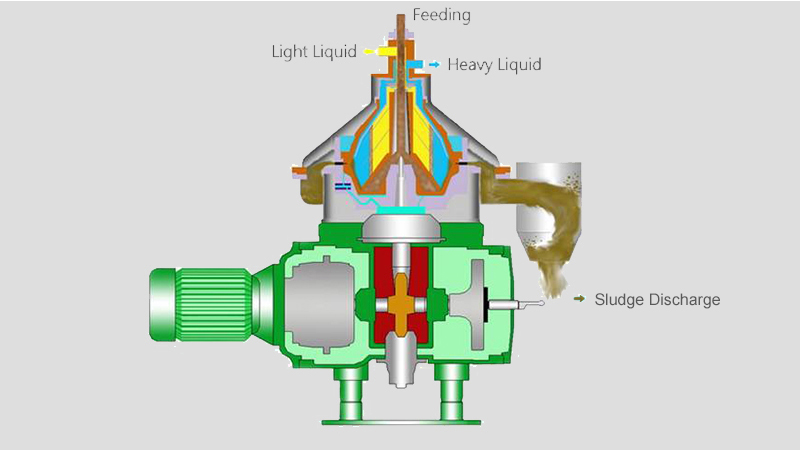

DISC STACK SEPARATOR WORKING PRINCIPLE

The separated material enters into the heart of the machine, that is, the inside of the bowl. Under the action of strong centrifugal force, the material passes through a set of disc bundle separation intervals. With the neutral holes of the disc as the interface, the liquid with larger specific gravity moves along the disc wall towards the outside the neutral hole, where heavy slag accumulates in the sediment area, and the heavy phase liquid flows upward to the centripetal pump; the lighter liquid with a smaller specific gravity moves along the disc wall into the neutral hole and converges to the lower centrifugal pump. The light and heavy liquid phases are discharged by the lower centrifugal pump and the upper centripetal pump respectively; the heavy slag is regularly discharged; continuous production is implemented.