Shenzhou - PVD System for Graphene Research Ion Arc Source Turbomolecular Pump Hot selling machine

With years of development, Shenzhou occupies an important position in the Metal Coating Machinery industry now. We are always in strict accordance with the international quality standards and quality management system, totally ensuring the product quality. Hot selling machine indeed plays an essential role in our everyday activities.The Best product are undeniably beautiful, legendary in their own way and yet timeless enough to remain popular throughout a brief period of time. In the future, Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd will continue to attach importance to the cultivation of talents, continuously improve the staff's business level and professional skills, strengthen technological innovation, and continuously enhance the comprehensive competitiveness of the company, in order to achieve'building a century-old evergreen enterprise and creating a well-known international brand' Work hard for this grand goal.

| Type: | Powder Coating Booth | Substrate: | Steel |

| Condition: | New | Machine Type: | powder coating plant, Spray Booths, Painting Equipment, Plc Controller Programmable Logic Controller, Pre-treatment Equipment, Conveying Equipment, Drying Oven, Curing oven, Coating Equipment, Anodized Equipment, Sandblasting Machine, Other |

| Video outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | New Product 2021 | Warranty of core components: | 1 Year |

| Core Components: | Motor | Coating: | Powder Coating |

| Place of Origin: | China | Brand Name: | LYSZ |

| Voltage: | Customers Local Voltage | Power: | 120KW |

| Warranty: | 1 Year | Key Selling Points: | Easy to Operate |

| Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company | Showroom Location: | None |

| Weight (KG): | 3500 |

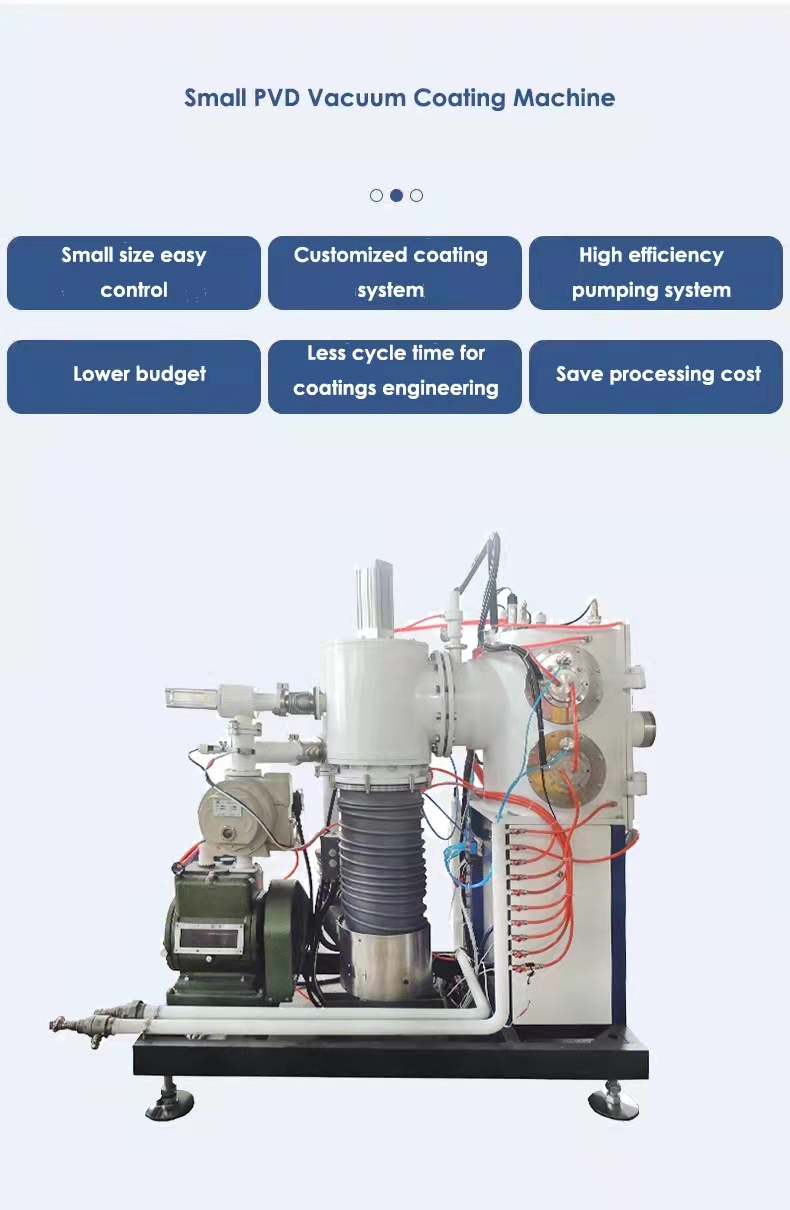

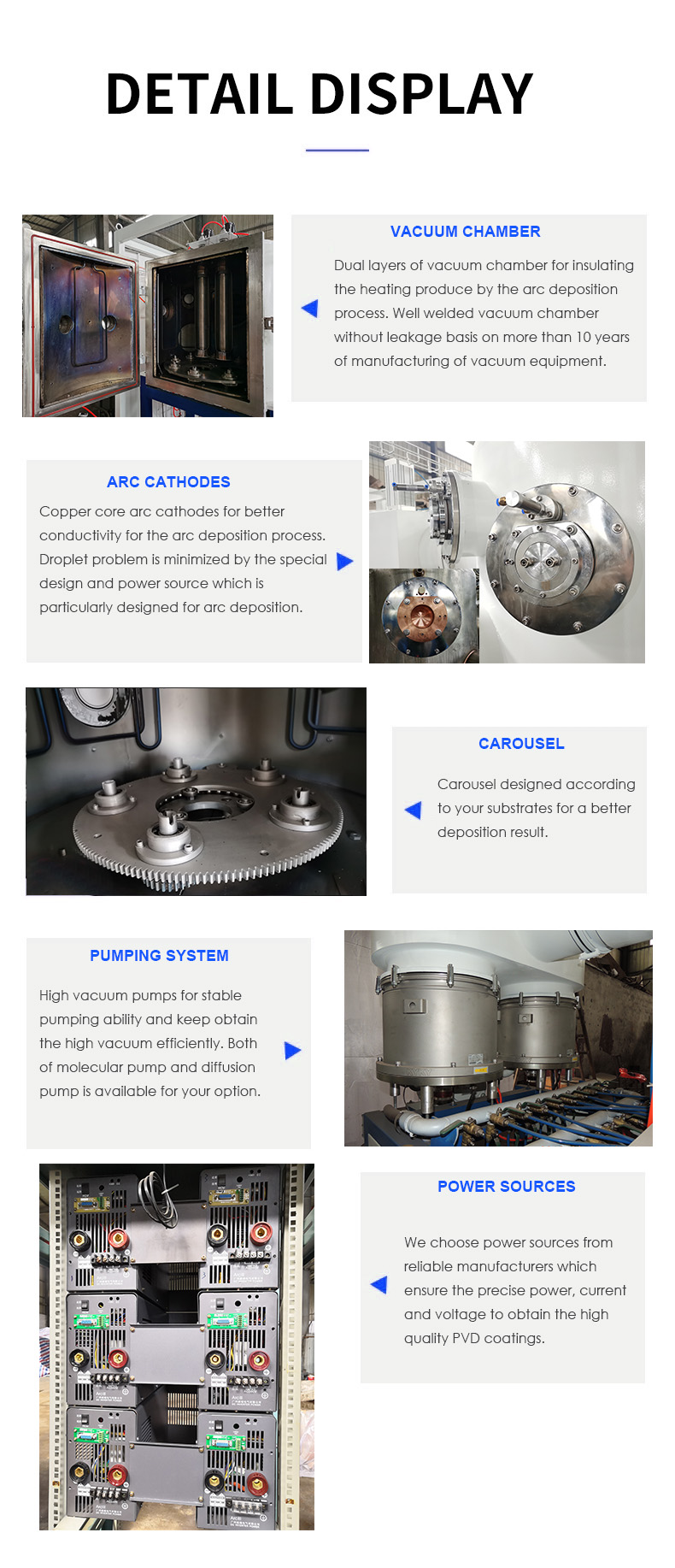

1. Droplets, a major defect of Cathodic arc deposition, are successfully minimized by our PVD arc ion plating machine.

2. Thick dense film with extremely smooth surface

3. High deposition rate by High energy density & High ionization

4. Multi-layer films & multi process films are possible

Arc deposition PVD coating equipment is capable to do depositions of many metals on different metals, ceramic and glassbsubstrates.

The PVD coating machine is particularly designed for protective hard coatings on tools, cutter and moulds. It improves the

lifetime of different types of tool, meantime, it can increases the surface hardness.

COMMON COATINGS | ||||

Coating | Features | Application | ||

TiN | Universal hard coating | It is mainly used as durable coating of turning, milling, drilling and gear cutting tools as well as the anti-adhesion of forming of forming and injection molds to improving lubricity. | ||

TiCN | Low Friction Coefficient and Excellent Hardness | The hardness of the coating is improved and the friction coefficient is lowed compared with TiN, It is mainly used for high-speed steel cutters, stamping dies, and forming dies. | ||

TiAlN | Universal Anti-Oxidation hard coating | With good red hardness and great surface smoothness, it can be used for high speed processing. Also, it is suitable for die steel, HSS, cement carbide tools (hardness of work material is lower than HRC45), stamping dies. | ||

CrN | Universal anti-corrosion hard coating, Low adherence tendency | With characteristics of good anti-adhesion, anti-corrosion and wear resistance. It is almost suitable for processing all materials including high silicon aluminum, stainless | ||

AlTiN | Ultra-high hardness, Anti- Oxidation | With very high micro-hardness and hot hardness, it is suitable for tool coatings with high thermal stress. It also has good thermal shock resistance and applicable for cement carbide tools (hardness of work material is lower than HRC45), die-casting molds. | ||

·Vacuum pumps

·Arc sources with arc power supplies

·O rings

·Vacuum meter with gauges/sensors

·Bias power supply

·Magnetic valves

·MFC

·Heating elements

·Target materials

·Customized jigs

We are based in Liaoning, China, start from 2018,sell to North America(30.00%),South America(10.00%),Southeast Asia(10.00%),South Asia(7.00%),Eastern Europe(5.00%),Oceania(5.00%),Mid East(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Central America(5.00%),Northern Europe(5.00%),Southern Europe(5.00%),Africa(3.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Separator,Centrifuge,Packing & Filling,Drying,Tabling Machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian