Shenzhou - Centrifugal Separator Disc Centrifuge

Centrifugal Separator has passed the tests conducted by our professional QC inspectors. Using materials that are offered by reliable raw materials suppliers,Decanter centrifuge,Disc Centrifuge,Tubular Centrifuge,Plate Centrifuge has stable yet powerful performance. It has so many advantages which are newly and independently developed, creating plenty of benefits.

5.0

Customization:

Customized logo (Min. Order: 1 Sets),Customized packaging (Min. Order: 1 Sets),Graphic customization (Min. Order: 1 Sets)

shipping:

Support Sea freight · Land freight

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

With immense market knowledge, we have been able to provide optimum quality Centrifugal Separator. Our professional engineers applied technology to product development.The product can be used in a wide range of applications like Separation Equipment requiring very high quality. Under the guidance of quality-oriented management theory, Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd continually ride the development trend of the times and continuously implement the strategic transformation. Our aim is to not only satisfy the needs of customers but also create needs for them.

| Place of Origin: | China | Type: | Separating Plant |

| Condition: | New | Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided | Marketing Type: | Hot product |

| Warranty of core components: | 1 Year | Core Components: | Bearing, Motor |

| Brand Name: | Shenzhou | Voltage: | 220v/300v/380v/optional |

| Power: | Model | Weight: | variable |

| Dimension(L*W*H): | variable | Warranty: | 1 Year |

| Key Selling Points: | Easy to Operate | Applicable Industries: | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Restaurant, Food Shop, Food & Beverage Shops, Advertising Company, Pharmaceutical plant, Chemical plant |

| Showroom Location: | None | Material: | Stainless Sheel |

| After-sales Service Provided: | Video technical support, Online support | After Warranty Service: | Video technical support, Online support |

| Local Service Location: | None | Certification: | CE BV ISO |

Product Description

Centrifugal Separator

LYSZ separators are designed for liquid-based applications. Using centrifugal force, they are used for separating suspensions consisting of two or more phases of different densities, i.e. they can be used for liquid-liquid separation, for liquid-liquid-solid separation or for liquid-solid separation. They are equally as effective at separating liquid mixtures at the same time as removing solids.

The main functions of the blood centrifuge series include the ability to handle high flow rates, high solids content and high temperature processing. These features make it ideal for dealing with harsh conditions in the animal and fish processing industries.

SHEN ZHOU Disc centrifuge is an automatic centrifugal separator for precipitated proteins, microbial broths, hormones and other biopharma applications. This separation system embodies more than 100 years of technical know-how and development and delivers the performance of centrifugal machines in pilot or medium scale set-ups. Designed for excellence, this solid-liquid separator can be used as a clarifier or a purifier and concentrator.

Feature:

Features

* High speed centrifugation to remove oil grease and sludge impurities

* Strong emulsification ability

* Low energy consumption,saves money

* Full automation possible with PLC automatic control panel.

* Centrifugal separation requiring no filter media.

* High reliability drive train system backed by delivery of over 1,000 units a year.

* Bowl design with superior separation performance and with good response to discharge loads.

* Pilot valve regulates total/partial discharge of solids.

* Super partial discharger (option) minimizes liquid loss and maximizes thickening of solid

* Fraction for discharge.

* Vibration-proof design realizes long working life.

* High speed centrifugation to remove oil grease and sludge impurities

* Strong emulsification ability

* Low energy consumption,saves money

* Full automation possible with PLC automatic control panel.

* Centrifugal separation requiring no filter media.

* High reliability drive train system backed by delivery of over 1,000 units a year.

* Bowl design with superior separation performance and with good response to discharge loads.

* Pilot valve regulates total/partial discharge of solids.

* Super partial discharger (option) minimizes liquid loss and maximizes thickening of solid

* Fraction for discharge.

* Vibration-proof design realizes long working life.

Working Principle

How does Disc Separator work?

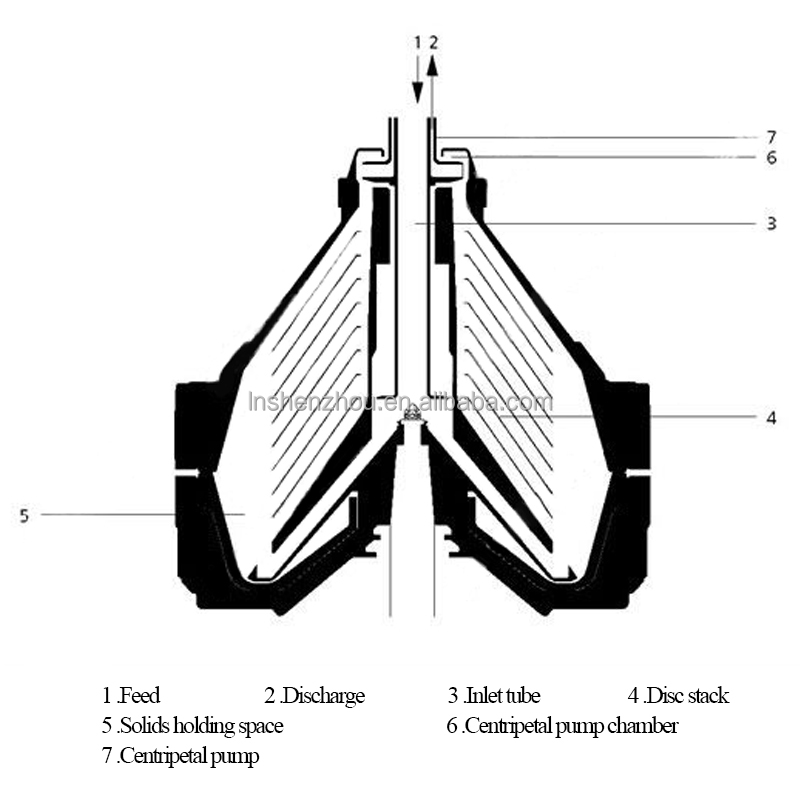

The disc separator is in vertical structure. The drum is mounted on the upper end of the vertical axis, which is driven by a motor and rotates at a high speed. There is a set of disc - shaped parts that are stacked together in the drum, with a small gap among them. When the suspension (or emulsion), which is pumped into the drum by feeding tube located in the center of the drum, pass through the gap between the discs, solid particles (or droplets) would settle down to form sediment (or liquid layer) on the disc by centrifuge force, and then the sediment slid along the surface of the disc and separated from the disc to accumulate in the largest diameter of the drum. At last, the separated liquid discharged from the outlet. The disc is utilized to shorten the settling distance of solid particles or droplets, enlarge the settlement area of the drum, and improve the production capacity of the separator. The solids accumulated in the drum are removed from the drum by manual after the machine stop, or out of the drum in the case of a dregs machine without stopping.

The disc separator is in vertical structure. The drum is mounted on the upper end of the vertical axis, which is driven by a motor and rotates at a high speed. There is a set of disc - shaped parts that are stacked together in the drum, with a small gap among them. When the suspension (or emulsion), which is pumped into the drum by feeding tube located in the center of the drum, pass through the gap between the discs, solid particles (or droplets) would settle down to form sediment (or liquid layer) on the disc by centrifuge force, and then the sediment slid along the surface of the disc and separated from the disc to accumulate in the largest diameter of the drum. At last, the separated liquid discharged from the outlet. The disc is utilized to shorten the settling distance of solid particles or droplets, enlarge the settlement area of the drum, and improve the production capacity of the separator. The solids accumulated in the drum are removed from the drum by manual after the machine stop, or out of the drum in the case of a dregs machine without stopping.

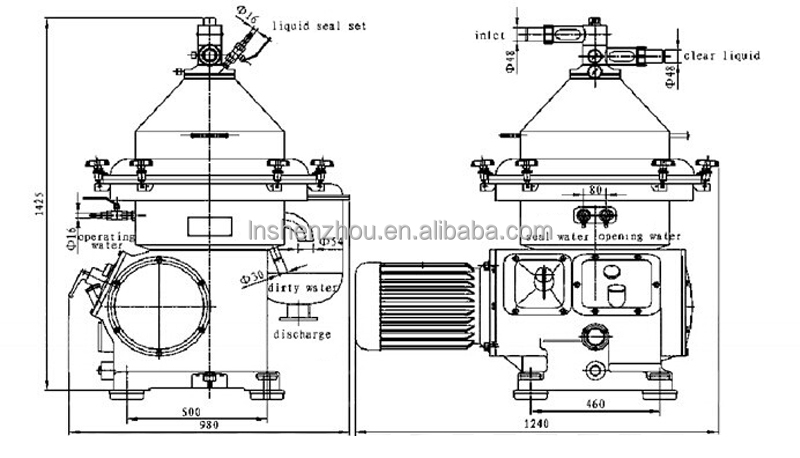

Main Structure

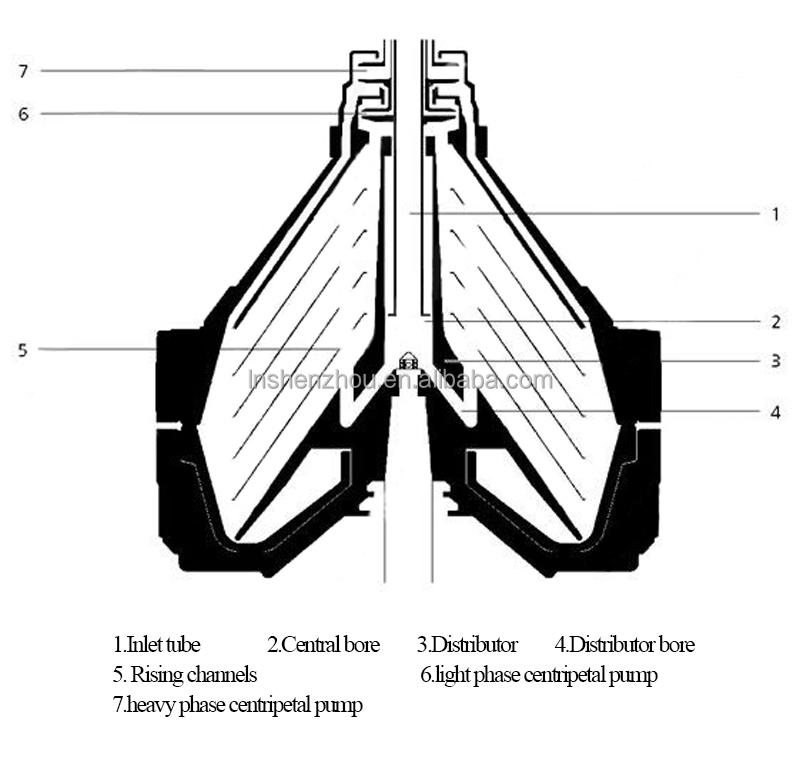

Powerful Motor provide power through the thermal coupling to drive drum in high-speed rotating around the main axis. And the liquid material is carried by feeding pipe located in the upper center into the bottom of the drum, and then led in the porthole below the disc and driven to the drum wall. Under centrifugal force, solid- liquid-liquid do the below motion to complete thorough separation:solid phrase, which is heavier than liquid, would sink into the inner wall of the drum for sediment formation; light liquid flow in centripetal pump, and be discharged by liquid outlet; The heavy liquid tends to the drum wall along the cone inside the disc, and then flows upward through through the heavy liquid concentric pump to be discharge from the outlet.

Due to the double-conical design of the inner cavity of the drum, it can compress the slag and increase its concentration.

Besides, some nozzles is mounted around the drum to spray slurry sediment, whose number and aperture are determined on the properties of the suspension, the degree of concentration and the amount of treatment.

In order to improve the slag concentration, recovery device is configured with this disc separator to the discharged sediment for reuse. For the solid concentration of the slag can be increased by 5~20 times than that of the feeding materials.

The processing capacity of the separator is up to 30t/h, which is suitable for suspension with solid phrase in diameter of 0.1~100 microns and concentration less than 10% (maximum to 25%).

Besides, some nozzles is mounted around the drum to spray slurry sediment, whose number and aperture are determined on the properties of the suspension, the degree of concentration and the amount of treatment.

In order to improve the slag concentration, recovery device is configured with this disc separator to the discharged sediment for reuse. For the solid concentration of the slag can be increased by 5~20 times than that of the feeding materials.

The processing capacity of the separator is up to 30t/h, which is suitable for suspension with solid phrase in diameter of 0.1~100 microns and concentration less than 10% (maximum to 25%).

The fields of application range from separating processes in the chemical and pharmaceutical industries through oil and fat recovery to the production of dairy products, beer, wine, fruit and vegetable juices, as well as the processing of mineral oil and mineral oil products.

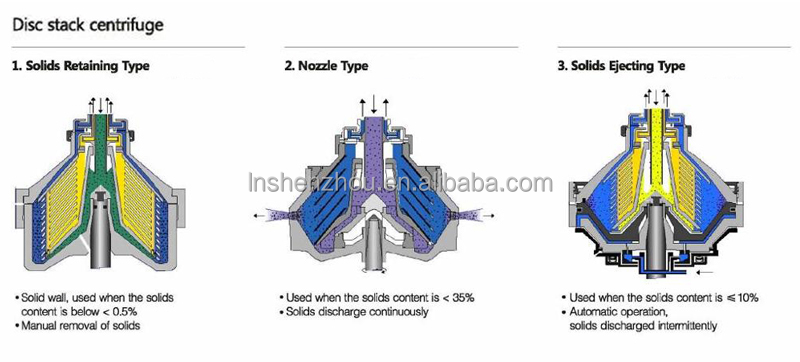

Separators have disk or annular chamber bowls. They operate continuously in respect of the discharge of the liquid phases. Inrespect of solids discharge they work either discontinuously (e.g. discontinuous disk-type centrifuges which must be stopped so that the collected solids can be removed by hand), semi-continuously (self-desludging disk type centrifuges = self-cleaning separators) or fully continuously (nozzle-type separators).

LYSZ separators are available with different types of drives: gear drive, belt drive, direct drive and integrated direct drive. The later is the next genuine stage in evolution in the separator construction process and works without motor shaft, gear, belts, coupling and motor bearing. The smaller number of installed components not only reduce the energy losses – they also reduce the maintenance costs, thus enhancing the availability of the machine. The space requirement of the integrated direct drive is approximately one third lower than is the case with equivalent gear or flat belt machines.

LYSZ separators with integrated direct drive can also be used in a very flexible manner. The bowl speed is infinitely variable within a specific range without change in transmission ratio. In addition, the maintenance process itself has been very much simplified. For instance, it is possible for the spindle to be taken out of the bearing housing only by loosening the bolts. The

innovative design of the integrated direct drive also enables the motor to be replaced complete with the drive within only a few hours when maintenance work has to be carried out – this is time which is very valuable and which can be used productively elsewhere.

Specification

Model | Treatment capacity (L/H) | Inlet Pressure (Mpa) | Outlet pressure (Mpa) | Motor power (Kw) | Weight (Kg) | Outline dimension (mm) |

DHSZ360 | 1200-2500 | 0.05 | 0.1-0.25 | 7.5 | 1280 | 1500*1150*1500 |

DHSZ470 | 2500-7000 | 0.05 | 0.1-0.25 | 15 | 1880 | 1800*1200*1800 |

DHSZ550A | 5000-10000 | 0.05 | 0.1-0.25 | 18.5 | 2200 | 1850*1550*2050 |

DHSZ550E | 6000-15000 | 0.05 | 0.1-0.25 | 22 | 2200 | 1850*1550*2050 |

DHSZ700 | 15000-30000 | 0.1 | 0.2 | 30 | 3300 | 2100*1650*2300 |

DRSZ360 | 1200-2500 | 0.05 | 0.1-0.25 | 5.5 | 750 | 1250*1050*1500 |

DRSZ400A | 2000-6000 | 0.05 | 0.1-0.3 | 7.5 | 1150 | 1300*900*1450 |

DRSZ400E | 4000-7500 | 0.05 | 0.1-0.3 | 7.5 | 1300 | 1300*900*1500 |

DRSZ550 | 6000-18000 | 0.05 | 0.1-0.3 | 22 | 2200 | 1620*1300*2200 |

Company Profile

Liaoyang Shenzhou Machinery Equipment Co., Ltd is a professional for supplier of pharmaceutical and chemical machine in China.We have a well-experienced team and a professional design institute,With rich experiences in pharmaceutical machinery and equipment including packing machine, centrifuge, falling film evaporator, distillation,mixer, tablet press machine, suppository production line,dryer,capsule filling machine ,capsule and so on.Our products are exported to many countries and areas, such as the USA, Korea, India, Indonesia,Thailand, Vietnam,Japan, Denmark,Romania, Bulgaria,Russia,South Africa, and so onAt the same time,our product with best prices and good quality,welcome to Shenzhou!

Packing & Delivery

wooden case

FAQ

1. who are we?

We are based in Liaoning, China, start from 1980 sell to South America(12.00%),Southeast Asia(10.00%),Northern Europe(10.00%),Southern Europe(10.00%),Domestic Market(10.00%),South Asia(8.00%),Central America(6.00%),North America(5.00%),Eastern Europe(5.00%),Africa(5.00%),Oceania(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Mid East(4.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Centrifuge,Separator,Packing machine,Drying machine,Filling & Sealing machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian

We are based in Liaoning, China, start from 1980 sell to South America(12.00%),Southeast Asia(10.00%),Northern Europe(10.00%),Southern Europe(10.00%),Domestic Market(10.00%),South Asia(8.00%),Central America(6.00%),North America(5.00%),Eastern Europe(5.00%),Africa(5.00%),Oceania(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Mid East(4.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Centrifuge,Separator,Packing machine,Drying machine,Filling & Sealing machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

GET IN TOUCH WITH Us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Copyright © 2025 Shenzhou Machinery is a core subsidiary of Shenzhou Group | Sitemap