Shenzhou - High Quality Glazed Tile Pressing Machinery Glazing Roof Tile Making Machinery Cold Foorming Machine Hot selling machine

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd has been focusing on improving technologies to develop new products on a regular basis. We have successfully made High Quality Glazed Tile Pressing Machinery Glazing Roof Tile Making Machinery Cold Foorming Machine launch to the public as scheduled. With its new features, Decanter centrifuge,Disc Centrifuge,Tubular Centrifuge,Plate Centrifuge is expected to lead the industry trend. In order to guarantee High Quality Glazed Tile Pressing Machinery Glazing Roof Tile Making Machinery Cold Foorming Machine performance, the adopted technologies are technically useful and feasible. Depending on its properties, the product is widely applied in the field(s) of Tile Making Machinery. Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd adhere to the corporate spirit of 'pragmatism & innovation' and aim to create benefits for our stakeholders. Driven by the fierce competition in the market, Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd hold a firm belief that we must focus on R&D and develop new technologies to adapt to the market trends.

| Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company | Showroom Location: | None |

| Condition: | New | Type: | Tile Cutting Machine |

| Tile Type: | Colored Glaze | Use: | WALL |

| Production Capacity: | 5 m/min | Place of Origin: | China |

| Brand Name: | lysz | Voltage: | 380V 50Hz 3phases |

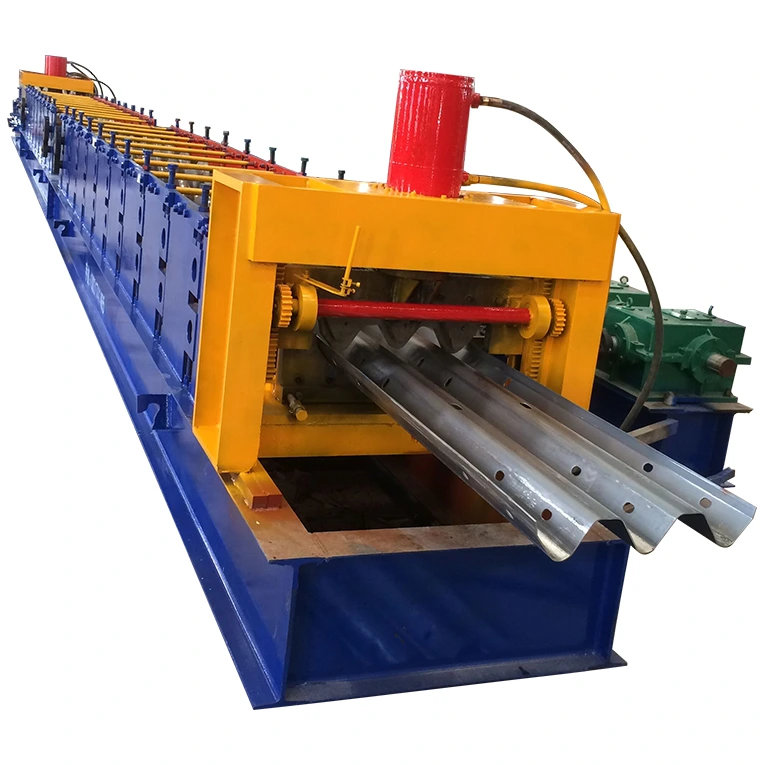

| Dimension(L*W*H): | 16000*2400*1600mm | Weight: | 450 kg |

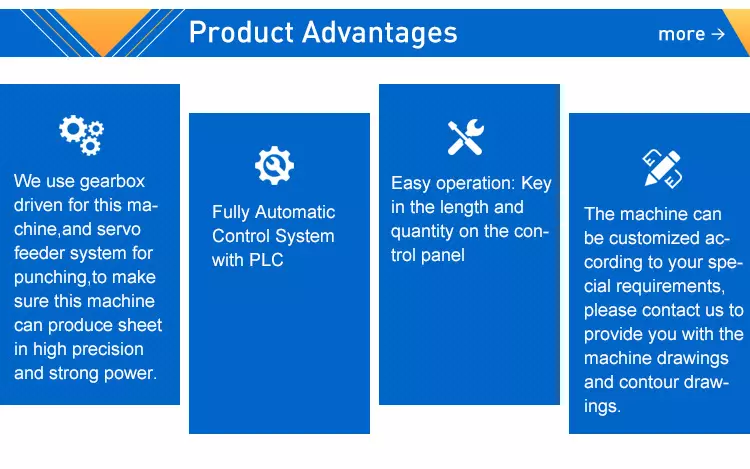

| Warranty: | 1 Year | Key Selling Points: | Easy to Operate |

| Rolling thinckness: | 0.3-0.8mm | Feeding width: | 1220mm |

| Machinery Test Report: | Provided | Video outgoing-inspection: | Provided |

| Marketing Type: | New Product 2021 | Warranty of core components: | 1 Year |

| Core Components: | Motor, Pump, PLC |

No. | Name | Unit | Qty |

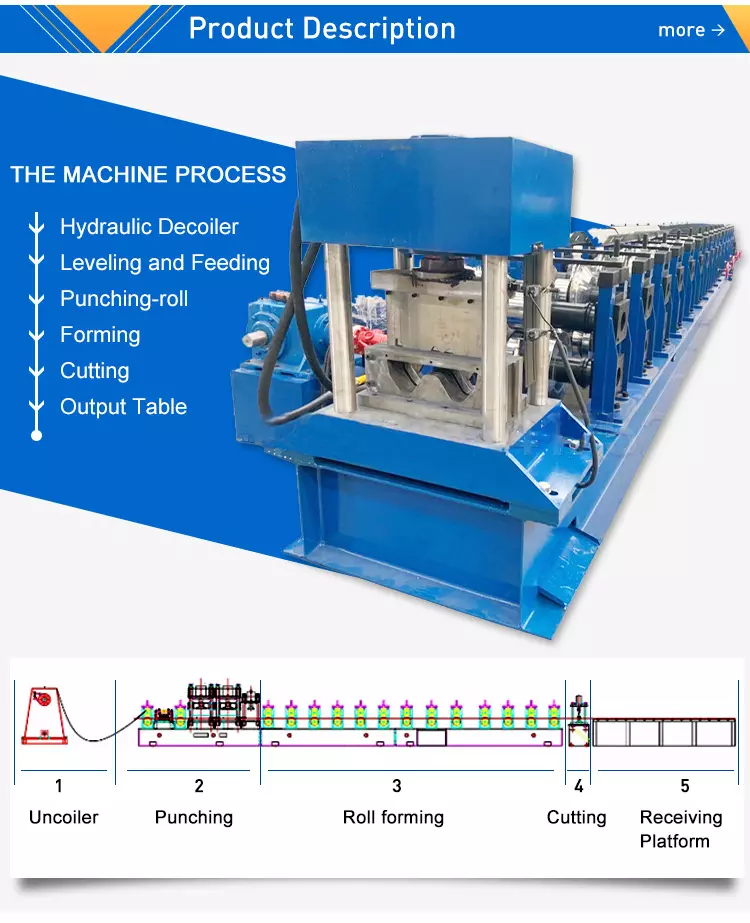

1 | Manual decoiler | set | 1 |

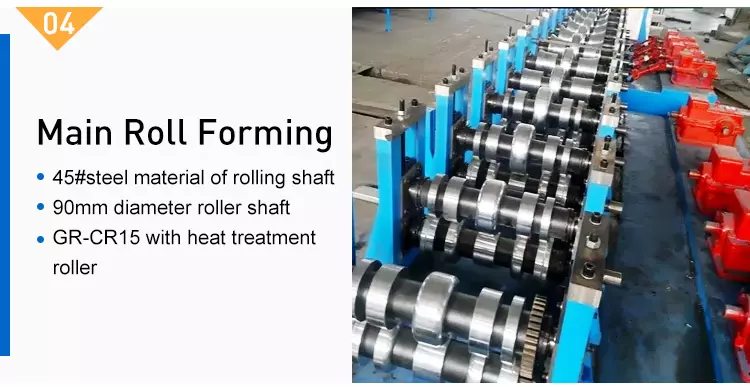

2 | Main forming machine | set | 1 |

3 | PLC control system | Set | 1 |

4 | Hydraulic pump station | set | 1 |

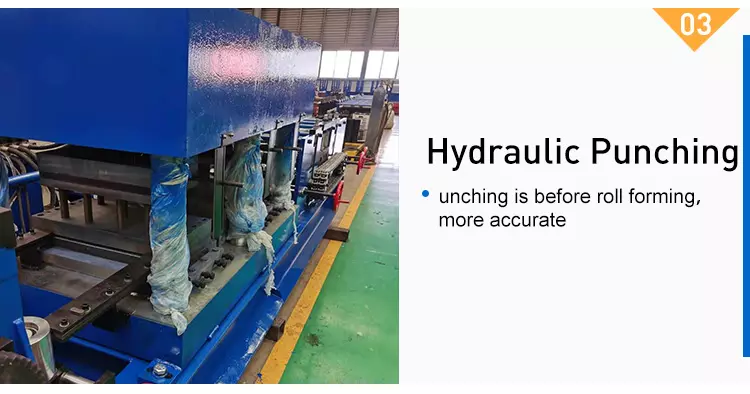

5 | post cut | set | 1 |

6 | electric motor | set | 1 |

7 | output table | set | 1 |

We are based in Liaoning, China, start from 2018,sell to North America(30.00%),South America(10.00%),Southeast Asia(10.00%),South Asia(7.00%),Eastern Europe(5.00%),Oceania(5.00%),Mid East(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Central America(5.00%),Northern Europe(5.00%),Southern Europe(5.00%),Africa(3.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Separator,Centrifuge,Packing & Filling,Drying,Tabling Machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian