Shenzhou - CE Approved LPG-25 High speed centrifugal spray dryer for spirulina Drying & granulator Machine

The product is made by technologies, some of which are developed on our own while others are learned from other famous brands.In the fields like Drying Equipment, our product is widely used for its versatility and guaranteed quality. It has been proved that high-end technologies can contribute to the high-efficiency manufacturing process.In the field(s) of Drying Equipment,CE Approved LPG-25 High speed centrifugal spray dryer for spirulina is widely accepted by users. We regard CE Approved LPG-25 High speed centrifugal spray dryer for spirulina product features as its core competitiveness. Adopting high-quality raw materials purchased from reliable suppliers,Shenzhou has the guaranteed quality and advantages of Decanter centrifuge,Disc Centrifuge,Tubular Centrifuge,Plate Centrifuge. Moreover, it has a look designed by our creative designers, making it highly attractive in its appearance.

| Type: | Spray Drying Equipment | Application: | Medicine Processing, Chemicals Processing, Food Processing |

| Condition: | New | Place of Origin: | China |

| Brand Name: | Shenzhou | Voltage: | 220V/380V |

| Power: | model choosing | Dimension(L*W*H): | model choosing |

| Key Selling Points: | Easy to Operate | Warranty: | 1 Year |

| Weight (KG): | 500 | Applicable Industries: | Food & Beverage Factory, Food & Beverage Shops |

| Showroom Location: | None | Marketing Type: | Hot Product 2019 |

| Machinery Test Report: | Provided | Video outgoing-inspection: | Provided |

| Warranty of core components: | 1 Year | Core Components: | PLC |

| Evaporation Capacity(kg/h): | 5 | Heating Method: | Electric Heating |

| Material: | SUS304, SUS304L, SUS316, SUS316L | Certification: | CE ISO9000 |

emulsion, soliquoid and pumpable paste states.

For this reason, when the particle size and distribution of the final products, their residual water contents, the stacking

density and the particle shape must meet the precision standard, the spray drying is one of the most desired technologies.

LPG High Speed Centrifugal Spray Dryer

Brief Indtroduction:

I . Working principle and configuration options:

The solution, emulsion, suspension liquid or slurry are sprayed into fine beads in the hot air, going down from the top of the drying chamber to the bottom, the water will be evaporated to and the product becomes powder or granular product.

Induce hot air from the top of drying tower, at the same time, pump the material liquid to the top of the tower by screw pump or peristaltic pump, the feeding solution becomes into fine beads or small droplets through the atomizer. When the droplets meet the high temperature hot air, the water will be evaporated immediately, and the material liquid is dried into dry product in a very short time, the product is discharged from the bottom of the drying tower, or from the cyclone (depend on the configuration). When the hot air contacts with the droplets, the temperature declines significantly, and the humidity increases greatly, and then will be exhausted by exhaust fan. The fine powder in the air will be collected through different separating devices There're different fine powder separation and recovery devices, such as cyclone (the common type and various combination type), bag filter, cyclone + bag filter, cyclone + wet scrubber, and bag filter + wet scrubber etc. We should different fine powder separation and recovery devices as per the characteristics of product and requirements of customer.

Depend on the product features and requirements, we might install secondary drying and cooling system (such as ZLG vibration fluid bed or pneumatic transportation), formulation system or powder sieving system etc after the spray dryer, or dehumidifier.

II . Features of our equipment:

The designs of our spray dryer are advanced in China, as well as worldwide. If we compare the important parameters of our spray dryers and some famous brand in the world, such as final moisture content, color, flavor, particle size, solubility and bulk density etc, they are very close, or sometimes, ours are even a little better. A lot of customers have achieved their desired results with our equipment.

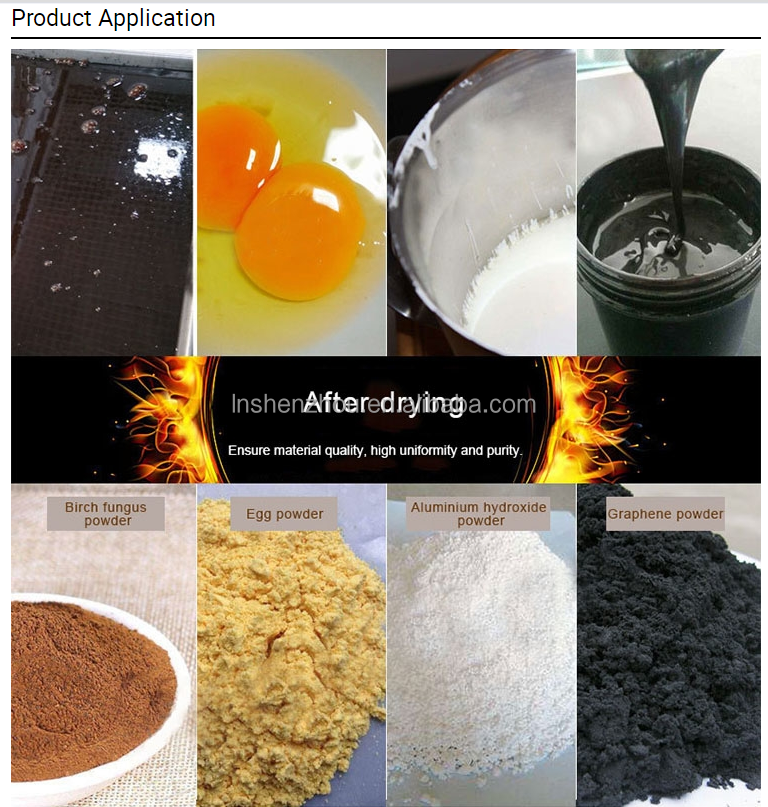

III . Applications

Food Industry: whole milk powder, cocoa milk powder, milk substitute, egg white (yolk), etc. armpit prion, Oats, chicken juice,instant tea, seasoning meat, protein, soybean, peanut protein, protein hydrolyzate, etc. Corn syrup, corn starch, glucose, pectin,maltose, potassium sorbate, pumpkin powder, etc.

Pharmaceutical products: Chinese traditional medicine extract (herb extract), medicine colloid, yeast, vitamins, antibiotics,

amylase, lipase, etc. Plastics resin: AB, ABS emulsion, urea-formaldehyde resin, phenolic resin, dense plastic (urea) formaldehyde resin, polyethylene, polyvinyl chloride, etc. Detergent: advanced washing powder, normal washing powder, soap powder, soda powder, emulsifiers, brighteners, phosphoric acid agents. Chemical Industry: Sodium fluoride (potassium), alkaline dyestuff and pigment,dye intermediates, Mn3O4, formic silica acid, catalyst, sulfuric acid agent, amino acids, silica, etc.. Ceramic: aluminum oxide,ceramic

Specification | LPG-5 | LPG-25 | LPG-50 | LPG-100 | LPG-150 | LPG-200 | |||||

Air Inlet temperature | 140-550 ° C (depend on the product to be dried, and URS) | ||||||||||

Air exhaust temperature | 60-120 ° C (depend on the product to be dried, and URS) | ||||||||||

Nominal water evaporationcapacity (Kg / h) | 5 | 25 | 50 | 100 | 150 | 200 | |||||

Heating method | High-pressure steam, or steam + electricity, or any kinds of fuel (diesel, natural gas, liquefiedpetroleum gas or coal, etc.), or solid fuel (any combustible material). Please specify. | ||||||||||

Drying tower diameter (mm) | 1100 | 1800 | 2150 | 2560 | 2860 | 3200 | |||||

Overall Dimensions (m) | 2×1.4×2.2 | 5×3×4 | 6×4×5 | 8×4×6 | 8×5×7 | 10×5×8 | |||||

Product yield | 95-99.9%_depend on the properties of the product and configurations | ||||||||||