Shenzhou - Industrial spray drying equipment for tomato powder / instant coffee / milk powder Drying & granulator Machine

Backed by our creative designers, experienced R&D experts, skilled technicians, etc. Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltdhas independently developed Industrial spray drying equipment for tomato powder / instant coffee / milk powder. It is the result of hard work and creative efforts and will come up to the expectation of users The accumulated rich experience and strong technological innovation capabilities have kept Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd at the forefront of the market, and Industrial spray drying equipment for tomato powder / instant coffee / milk powder developed have perfectly solved the pain points of the industry and the market. In the future,Industrial spray drying equipment for tomato powder / instant coffee / milk powder will always adhere to the road of quality development, increase the investment in technology and talent introduction, always improve the core competitiveness of the enterprise, to achieve the goal of sustainable development.

| Type: | Drying Oven | Application: | Medicine Processing, Chemicals Processing, Plastics Processing, Food Processing |

| Condition: | New | Place of Origin: | Liaoning, China |

| Brand Name: | LYSZ | Voltage: | 380V |

| Power: | 18-50kw | Dimension(L*W*H): | 1.8*0.9*2.2mm-5.5*4.5*7mm |

| Key Selling Points: | High Safety Level | Warranty: | 1 Year |

| Weight (KG): | 1500 | Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company |

| Showroom Location: | None | Marketing Type: | Hot Product 2019 |

| Machinery Test Report: | Provided | Video outgoing-inspection: | Provided |

| Warranty of core components: | 1 Year | Core Components: | PLC |

| Evaporation Capacity(kg/h): | 100 | Heating Method: | Electric Heating |

| Material: | SUS304 |

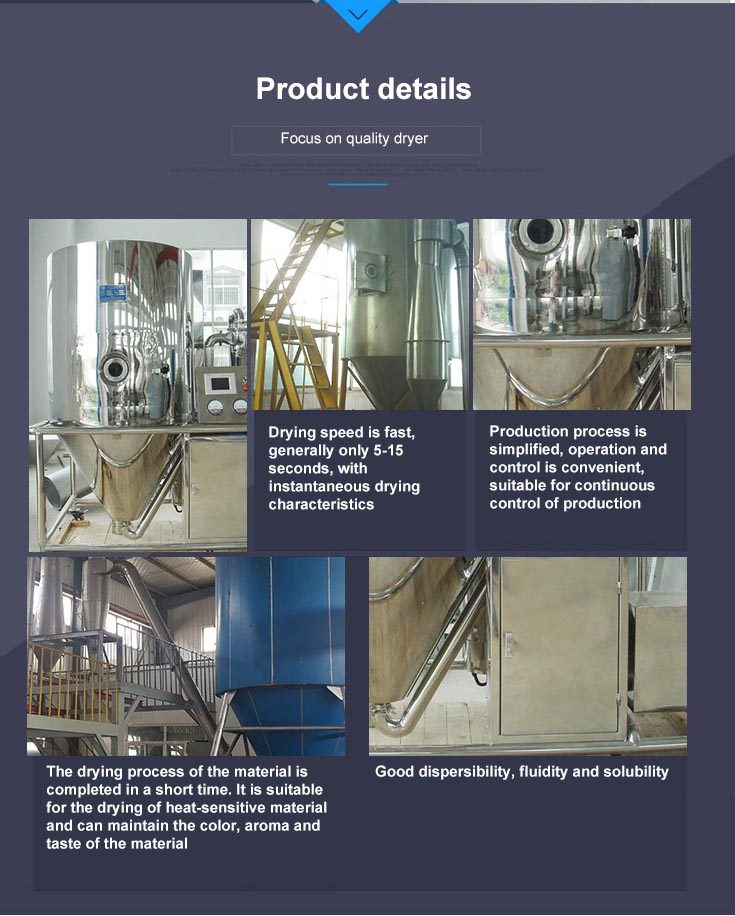

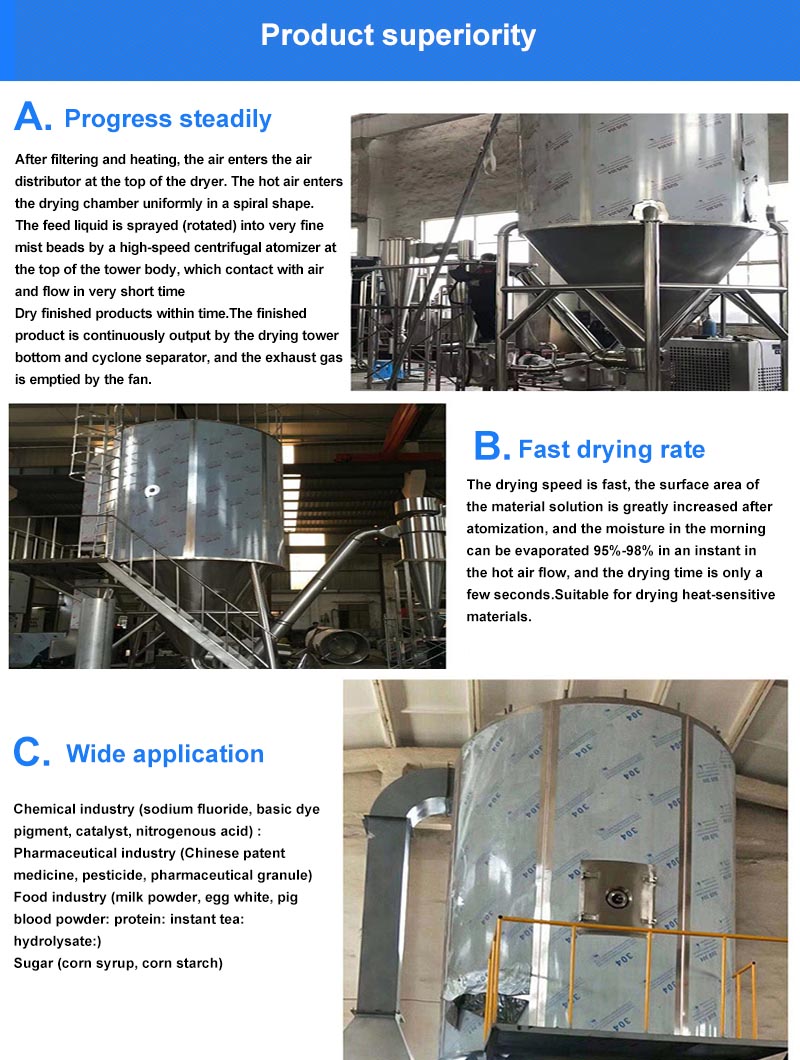

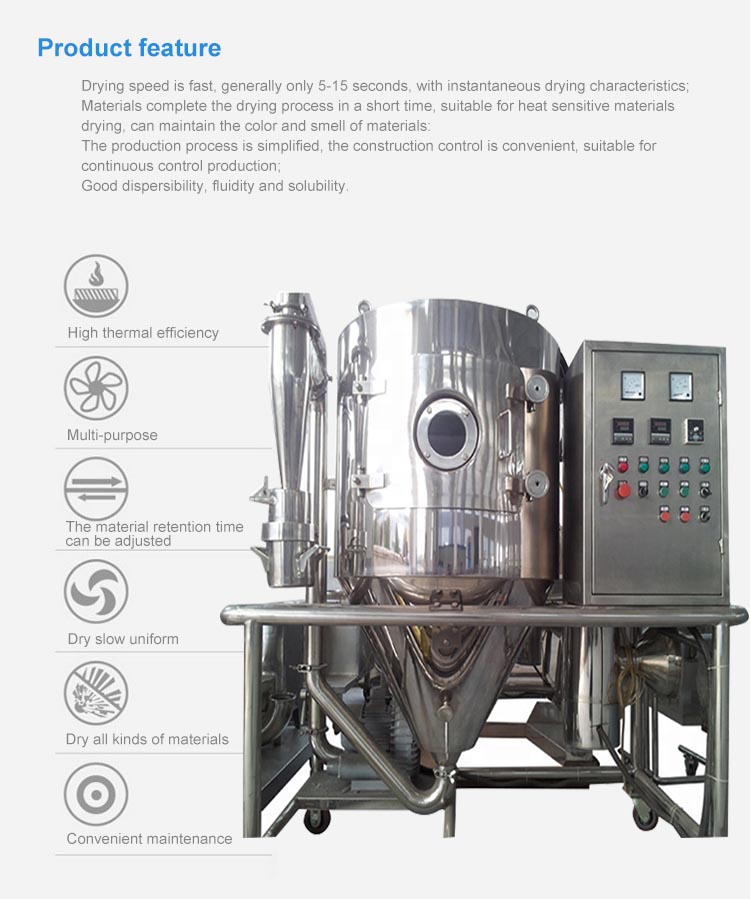

Working Process soymilk dryer.

Technical parameters | ||||||||||||||||||

Model | 5 | 25 | 50 | 100 | 150 | 200 | 500 | 1000 | 2000-6000 | |||||||||

Inlet temperature(℃) | Technical parameters | |||||||||||||||||

Outlet temperature( ℃) | 80-90 | |||||||||||||||||

Spraying method | High-speed centrifugal atomizer (Mechanical transmission or stepless variable frequency speed regulating) | |||||||||||||||||

Moisture evaporating ability(kg/h) | 5 | 25 | 50 | 100 | 150 | 200 | 500 | 1000 | 2000-6000 | |||||||||

Rotary speed(rpm) | 25000 | 22000 | 21500 | 18000 | 16000 | 12000-13000 | It is decided by the process, the site condition and the user's requirement. | |||||||||||

Body diameter(m) | 1.2 | 1.9 | 2.2 | 2.56 | 2.96 | 3.36 | 5.2 | 7.6 | ||||||||||

Diameter of atomizing disc | 60 | 120 | 150 | 180-210 | ||||||||||||||

Transmission power(kw) | 4.2 | 14 | 18 | 28 | 37 | 43 | 76 | 109 | ||||||||||

Heating power(kw) | 9 | 36 | 48 | 72 | 84 | 96 | 144 | |||||||||||

Recovered dry power(%) | >95 | |||||||||||||||||

Nozzle's lifting height(m) | -- | 2.5 | 3.2 | It is decided by the process. | ||||||||||||||

We are based in Liaoning, China, start from 2018,sell to North America(30.00%),South America(10.00%),Southeast Asia(10.00%),South Asia(7.00%),Eastern Europe(5.00%),Oceania(5.00%),Mid East(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Central America(5.00%),Northern Europe(5.00%),Southern Europe(5.00%),Africa(3.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Separator,Centrifuge,Packing & Filling,Drying,Tabling Machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian