Shenzhou - Coffee Egg Milk Powder Making Centrifugal Spray Drying Machine/Industrial drying machine egg powder spray drying machine Drying & granulator Machine

We have been continuously improving technical capabilities in manufacturing the Coffee Egg Milk Powder Making Centrifugal Spray Drying Machine/Industrial drying machine egg powder spray drying machine since established. The product is appropriate to different uses in Drying Equipment.

5.0

Customization:

Customized logo (Min. Order: 1 Units),Customized packaging (Min. Order: 1 Units),Graphic customization (Min. Order: 1 Units)

shipping:

Support Sea freight · Land freight

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Coffee Egg Milk Powder Making Centrifugal Spray Drying Machine/Industrial drying machine egg powder spray drying machine launched by Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd has a clear positioning and is a product designed to solve industry pain points. It has been proved that high-end technologies can contribute to the high-efficiency manufacturing process.In the field(s) of Drying Equipment,Coffee Egg Milk Powder Making Centrifugal Spray Drying Machine/Industrial drying machine egg powder spray drying machine is widely accepted by users. Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd with high quality and good reputation, it has won a good reputation in the industry.

| Type: | Drying Oven | Application: | Medicine Processing, Chemicals Processing, Plastics Processing, Food Processing |

| Condition: | New | Place of Origin: | Liaoning, China |

| Brand Name: | LYSZ | Voltage: | 380V |

| Power: | 18-50kw | Dimension(L*W*H): | 1.8*0.9*2.2mm-5.5*4.5*7mm |

| Key Selling Points: | High Safety Level | Warranty: | 1 Year |

| Weight (KG): | 1500 | Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company |

| Showroom Location: | None | Marketing Type: | Hot Product 2019 |

| Machinery Test Report: | Provided | Video outgoing-inspection: | Provided |

| Warranty of core components: | 1 Year | Core Components: | PLC |

| Evaporation Capacity(kg/h): | 100 | Heating Method: | Electric Heating |

| Material: | SUS304 |

Product Description

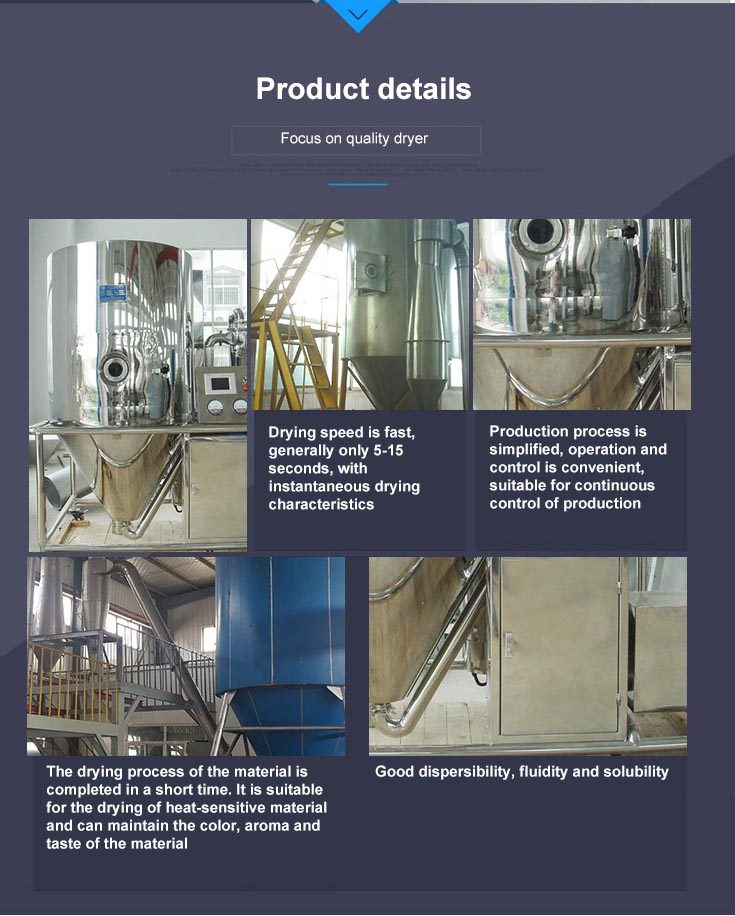

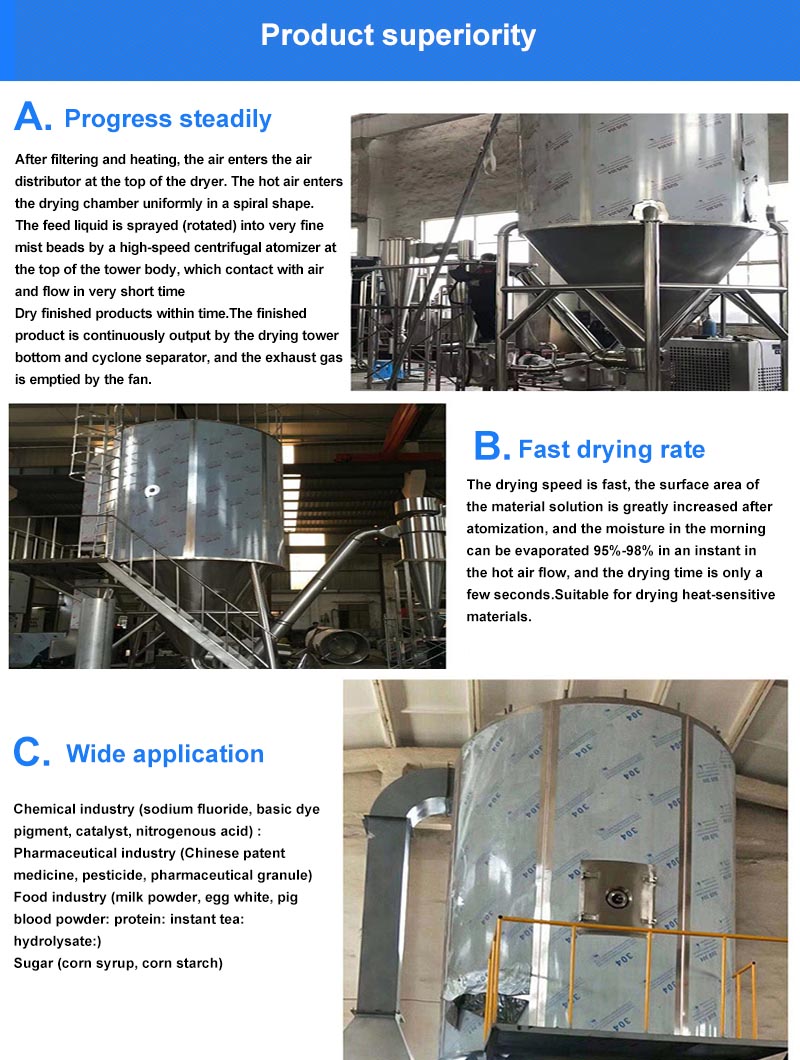

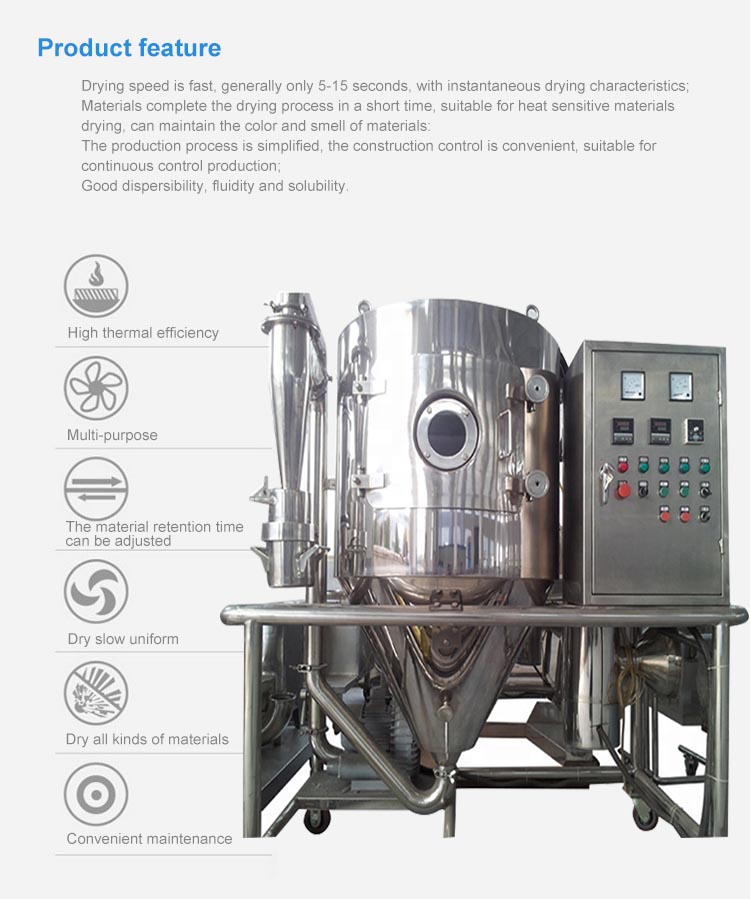

LPG Series High Speed Centrifugal Spray Dryer is the technology most widely used in the liquid technology shaping and in the drying industry. The drying technology is most suitable for producing solid powder or particle products from liquid materials, such as solution , emulsion, suspension and pumpable paste states, For this reason, when the particle size and distribution of the final products, residual water contents, mass density and the particle shape must meet the precise standard, spray drying is one of the most desired technologies.

Working Process soymilk dryer.

After been filtered and heated the Air enters into the air distributor on the top of the dryer .The Hot Air enters into the drying room in the spiral form and uniformly. Passing through the high-speed centrifugal Sprayer/Atomizer on the top of the tower, the material liquid will rotate and be sprayed into the extremely fine mist liquid beads .Through the very short time of contacting the heat air, the materials can be dried into the Final products .The final products will be Discharged continuously from the bottom of the drying tower and from the cyclones. The waste gas will be discharged from blower..

Specification

Technical parameters | ||||||||||||||||||

Model | 5 | 25 | 50 | 100 | 150 | 200 | 500 | 1000 | 2000-6000 | |||||||||

Inlet temperature(℃) | Technical parameters | |||||||||||||||||

Outlet temperature( ℃) | 80-90 | |||||||||||||||||

Spraying method | High-speed centrifugal atomizer (Mechanical transmission or stepless variable frequency speed regulating) | |||||||||||||||||

Moisture evaporating ability(kg/h) | 5 | 25 | 50 | 100 | 150 | 200 | 500 | 1000 | 2000-6000 | |||||||||

Rotary speed(rpm) | 25000 | 22000 | 21500 | 18000 | 16000 | 12000-13000 | It is decided by the process, the site condition and the user's requirement. | |||||||||||

Body diameter(m) | 1.2 | 1.9 | 2.2 | 2.56 | 2.96 | 3.36 | 5.2 | 7.6 | ||||||||||

Diameter of atomizing disc | 60 | 120 | 150 | 180-210 | ||||||||||||||

Transmission power(kw) | 4.2 | 14 | 18 | 28 | 37 | 43 | 76 | 109 | ||||||||||

Heating power(kw) | 9 | 36 | 48 | 72 | 84 | 96 | 144 | |||||||||||

Recovered dry power(%) | >95 | |||||||||||||||||

Nozzle's lifting height(m) | -- | 2.5 | 3.2 | It is decided by the process. | ||||||||||||||

Company Profile

Liaoyang Shenzhou Machinery Equipment Co., Ltd is a professional for supplier of pharmaceutical and chemical machine in China.We have a well-experienced team and a professional design institute,With rich experiences in pharmaceutical machinery and equipment including packing machine, centrifuge, falling film evaporator, distillation,mixer, tablet press machine, suppository production line,dryer,capsule filling machine ,capsule and so on.Our products are exported to many countries and areas, such as the USA, Korea, India, Indonesia,Thailand, Vietnam,Japan, Denmark,Romania, Bulgaria,Russia,South Africa, and so onAt the same time,our product with best prices and good quality,welcome to Shenzhou!

FAQ

1. who are we?

We are based in Liaoning, China, start from 2018,sell to North America(30.00%),South America(10.00%),Southeast Asia(10.00%),South Asia(7.00%),Eastern Europe(5.00%),Oceania(5.00%),Mid East(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Central America(5.00%),Northern Europe(5.00%),Southern Europe(5.00%),Africa(3.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Separator,Centrifuge,Packing & Filling,Drying,Tabling Machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian

We are based in Liaoning, China, start from 2018,sell to North America(30.00%),South America(10.00%),Southeast Asia(10.00%),South Asia(7.00%),Eastern Europe(5.00%),Oceania(5.00%),Mid East(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Central America(5.00%),Northern Europe(5.00%),Southern Europe(5.00%),Africa(3.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Separator,Centrifuge,Packing & Filling,Drying,Tabling Machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

GET IN TOUCH WITH Us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Copyright © 2025 Shenzhou Machinery is a core subsidiary of Shenzhou Group | Sitemap