Shenzhou - Automatic straight line paste filler creams tube filling machine for shampoo oil tomato sauce paste filling machine Filling&Packing Machine

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd are confident that we will make great achievements in the future. We will unite all the elites and talents in the industry and rely on their wisdom and experience to help us upgrade our existing products and develop new products. This will make great contributions to the company development.

5.0

Customization:

Customized logo (Min. Order: 1 Sets),Customized packaging (Min. Order: 1 Sets),Graphic customization (Min. Order: 1 Sets)

shipping:

Support Sea freight · Land freight

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Having absorbed the best and the brightest to join us, Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd finds it easier and more efficient to develop products on a regular basis.Automatic straight line paste filler creams tube filling machine for shampoo oil tomato sauce paste filling machine is the newest result combining all the efforts and wisdom of our employees. Talents and technology are indispensable supporting factors for the Automatic straight line paste filler creams tube filling machine for shampoo oil tomato sauce paste filling machine to be widely praised. Compared with the traditional ones, it better meets the market demands.

| Type: | Filling Machine | Applicable Industries: | Manufacturing Plant, Food & Beverage Factory, Farms, Food Shop, Printing Shops, Construction works , Energy & Mining |

| Showroom Location: | Egypt, Italy, Viet Nam, Pakistan, Russia, None | Condition: | New |

| Application: | Food, Beverage, Chemical | Packaging Type: | CANS, Bottles |

| Packaging Material: | Glass | Automatic Grade: | Automatic |

| Driven Type: | Electric | Voltage: | AC110-380V |

| Place of Origin: | China | Brand Name: | Shenzhou |

| Dimension(L*W*H): | 2000*960*1300mm | Weight: | 450 KG |

| Warranty: | 1 Year | Key Selling Points: | High-accuracy |

| Machinery Capacity: | 1500BPH | Filling Material: | Beer, Milk, Water, Oil, Juice |

| Filling Accuracy: | 0.05%F.S. | Marketing Type: | Hot Product 2019 |

| Machinery Test Report: | Provided | Video outgoing-inspection: | Provided |

| Warranty of core components: | 1 Year | Core Components: | Motor |

| Bottle type: | PET Plastic Bottle Glass Bottle | Product name: | Automatic Liquid Filling Machine |

| Keywords: | Liquid paste Filling Machine | Filling nozzles: | 1/2/4/8/10 |

Product Description

Automatic straight line paste filler creams tube filling machine for shampoo oil tomato sauce paste filling machine

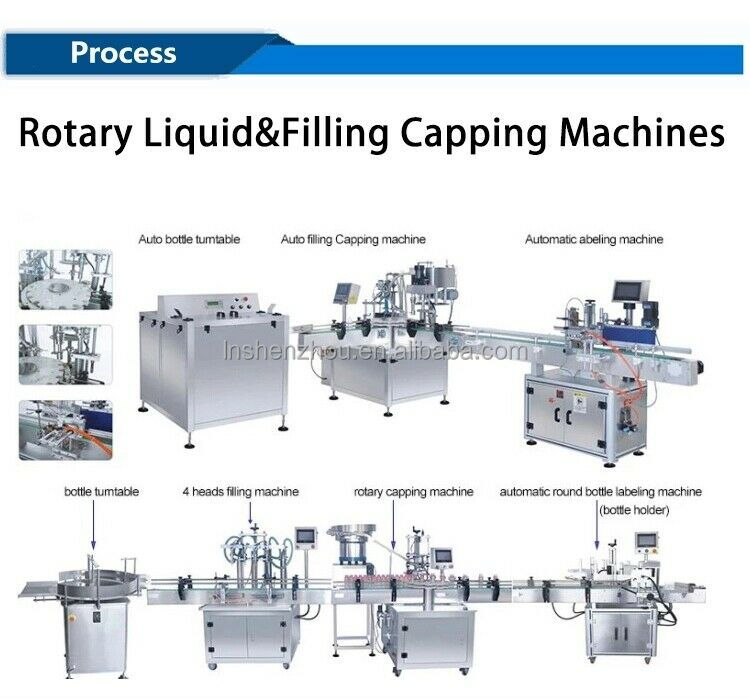

This machine can be connected to other equipment as a production line

1/2/4/8/10 heads Automatic Mineral Water Filling Machine into PET Bottles

Brief introduction:The automatic filling machine is integrated with electricity and pneumatic control with accurate, simple

operation and convenient maintenance feature.It can be widely used in the automatic packaging production of liquid such as water and various juice or oils.

Feature:

Brief introduction:The automatic filling machine is integrated with electricity and pneumatic control with accurate, simple

operation and convenient maintenance feature.It can be widely used in the automatic packaging production of liquid such as water and various juice or oils.

Feature:

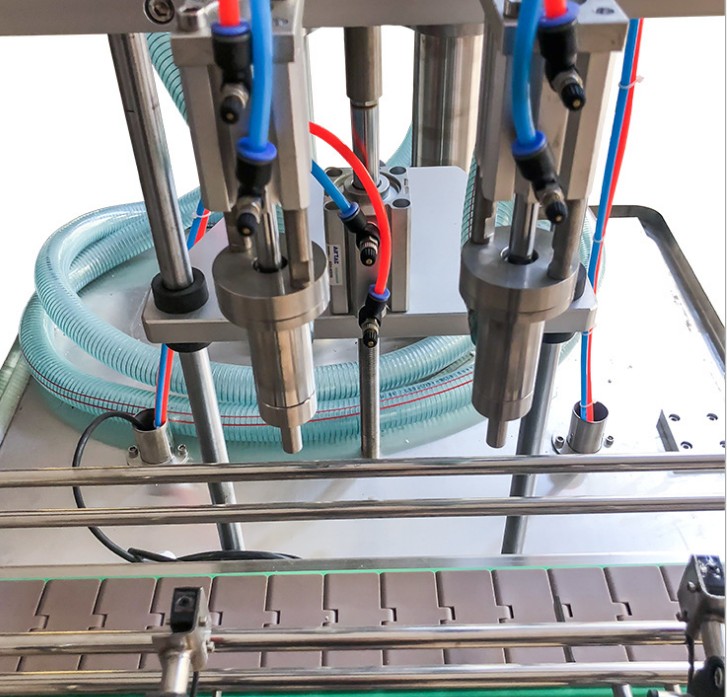

1. Imported sealing device to take effective anti-drip measures to ensure no dripping on the spot.

2. High-precision piston metering device, measuring by cylinder driven, much more accurate and much more reliable

3. Mufti-language colorful control interface, setting device parameters is intuitive and simple.

4. The filling head is equipped with an independent vacuum suck-back

device, and the grease is uniformly recovered.

device, and the grease is uniformly recovered.

5. All electrical accessories are world famous brands, stable and durable in

operation.

operation.

Specification

Material | 304 Stainless Steel |

Filling Nozzle | 2,4,6,8 |

Filling Speed | 1200-1500 bottles/h(According to the filling quantity) |

Can Height | 30-350mm |

Can diameter | 10-200mm |

Air Source | 0.6-0.8MPa |

Filling Volume | 100 - 500ml, 500ml - 5L |

Weight | 450kg |

Voltage | 2000*960*1300mm |

Details Images

Company Profile

Liaoyang Shenzhou Machinery Equipment Co., Ltd is a professional for supplier of pharmaceutical and chemical machine in China.We have a well-experienced team and a professional design institute,With rich experiences in pharmaceutical machinery and equipment including packing machine, centrifuge, falling film evaporator, distillation,mixer, tablet press machine, suppository production line,dryer,capsule filling machine ,capsule and so on.Our products are exported to many countries and areas, such as the USA, Korea, India, Indonesia,Thailand, Vietnam,Japan, Denmark,Romania, Bulgaria,Russia,South Africa, and so onAt the same time,our product with best prices and good quality,welcome to Shenzhou!

Packing & Delivery

Automatic Liquid Packing Filling Machine

1 .inner package:stretch film.

2.outside package:standard export wooden case(Packaging according to the specific legal requirements of customer country).

1 .inner package:stretch film.

2.outside package:standard export wooden case(Packaging according to the specific legal requirements of customer country).

Our Service

•12 months long guarantee period from machine arriving date.

•Abundant spare parts in stock are available to provide.

•Our technicians could be dispatched for overseas service.

•24 hours technical consultation.

•Routine tracing till the machine work properly will be done timely.

•We will remind you to do the normal maintenance.

•Your suggestions or any comments & reflection would be treated in priority.

•Your workers can get training easily by net video.

•Abundant spare parts in stock are available to provide.

•Our technicians could be dispatched for overseas service.

•24 hours technical consultation.

•Routine tracing till the machine work properly will be done timely.

•We will remind you to do the normal maintenance.

•Your suggestions or any comments & reflection would be treated in priority.

•Your workers can get training easily by net video.

FAQ

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

GET IN TOUCH WITH Us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Copyright © 2025 Shenzhou Machinery is a core subsidiary of Shenzhou Group | Sitemap