Shenzhou - LYSZ Water Treatment Sludge Dewatering Screw Press Slaughteringhouse Manure Dewatering Decanter centrifuge

With strong ability of product research and development, Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd ensures new products are launched on a regular basis. Our new product LYSZ Water Treatment Sludge Dewatering Screw Press Slaughteringhouse Manure Dewatering is a totally new series and has different features. Our product can be tailored to suit you perfectly. Following scientific and advanced production standards, we have successfully made LYSZ Water Treatment Sludge Dewatering Screw Press Slaughteringhouse Manure Dewatering excellent in its performance. Through multiple times of tests, the Decanter centrifuge,Disc Centrifuge,Tubular Centrifuge,Plate Centrifuge is proved to be of great and so on. Before its launch, it has passed the certifications of several international and national authorities.

| Place of Origin: | China | Type: | Centrifuge |

| Product Type: | Plant | Condition: | New |

| Video outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | New Product 2020 | Warranty of core components: | 1 Year |

| Core Components: | PLC, Bearing, Gearbox, Motor | Brand Name: | Shenzhou |

| Voltage: | 380V/50HZ,3Phase | Power: | Model |

| Weight: | 2000 | Dimension(L*W*H): | Model |

| Warranty: | 1 Year | Key Selling Points: | Easy to Operate |

| Applicable Industries: | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Construction works , Food & Beverage Shops, Chemical plant, pharmaceutical plant | Showroom Location: | None |

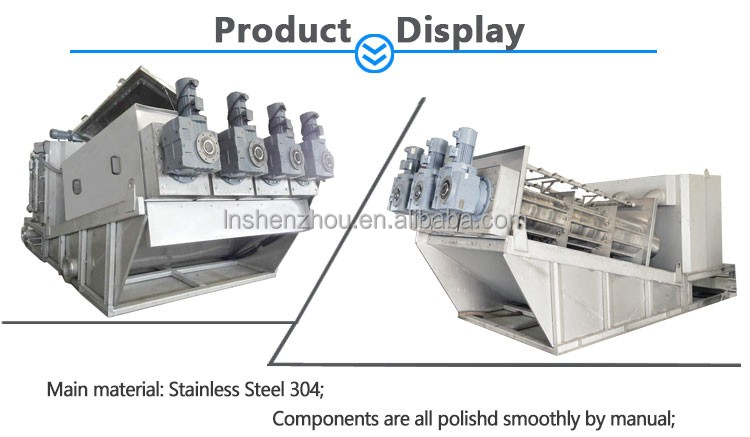

| Material: | Stainless Steel |

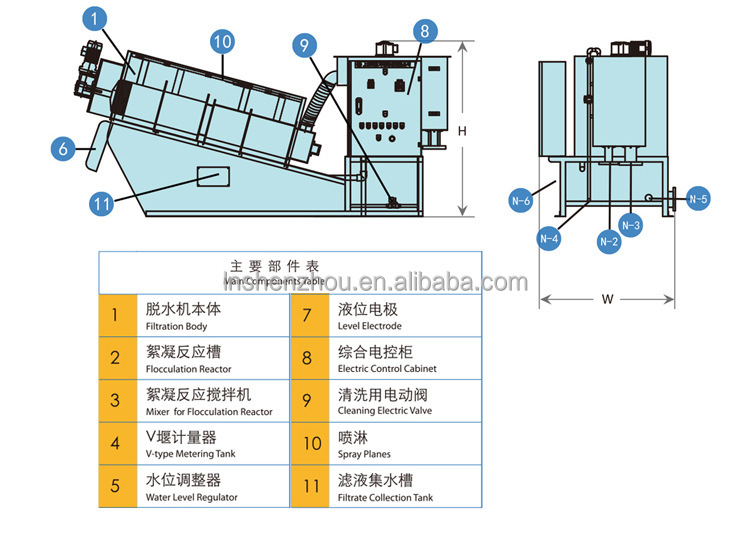

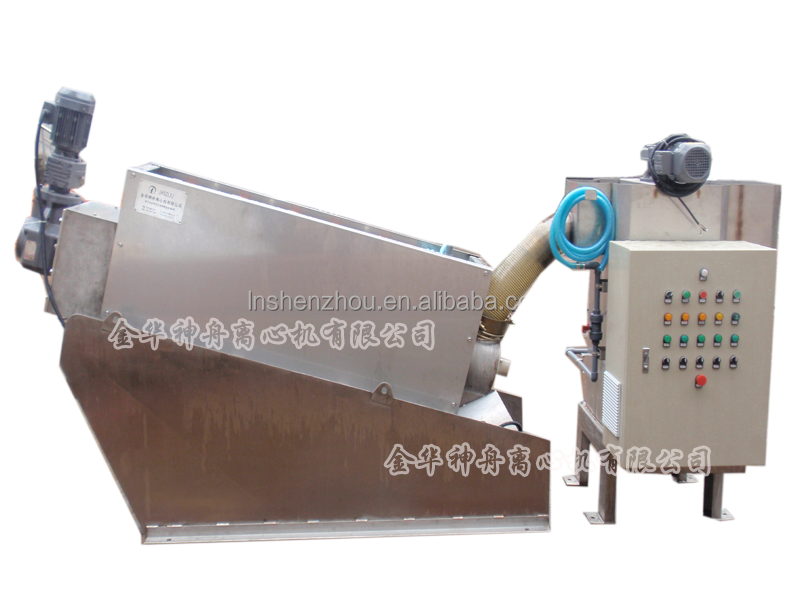

dewatering, proper pressure and extension of the dewatering path, which solves the problem of the easy clogging of previous generations of sludge dewatering equipment and the inability to treat low-concentration sludge and oily sludge. , High energy consumption, complex operation and other technical problems, to achieve the goal of efficient and energy-saving dehydration. The dewatering machine can realize high-efficiency flocculation under the condition of fully automatic operation, and continuously complete the sludge thickening and squeezing dewatering work, and finally return or discharge the collected filtrate. It is widely used in municipal sewage treatment projects and water treatment systems in food, starch, oil, pharmaceutical, chemical, paper, leather and other industries.

Model | DS Sludge Treating Capacity | Sludge Flow Treating Capacity | Weight (KG) | ||||||||

10000mg/L | 20000mg/L | 30000mg/L | 40000mg/L | 50000mg/L | |||||||

SZ101 | 5-7kg/h | ~0.5m3/h | ~0.25m3/h | ~0.2m3/h | ~0.15m3/h | ~0.14m3/h | 220 | ||||

SZ131 | 10-14kg/h | ~1m3/h | ~0.5m3/h | ~0.4m3/h | ~0.3m3/h | ~0.28m3/h | 250 | ||||

SZ201 | 15-20kg/h | ~1.5m3/h | ~0.75m3/h | ~0.6m3/h | ~0.5m3/h | ~0.4m3/h | 420 | ||||

SZ202 | 30-40kg/h | ~3m3/h | ~1.5m3/h | ~1.2m3/h | ~1.0m3/h | ~0.8m3/h | 550 | ||||

SZ203 | 45-60kg/h | ~4.5m3/h | ~2.25m3/h | ~1.8m3/h | ~1.5m3/h | ~1.2m3/h | 700 | ||||

SZ301 | 50-70kg/h | ~5m3/h | ~2.5m3/h | ~2m3/h | ~1.5m3/h | ~1.4m3/h | 900 | ||||

SZ302 | 100-140kg/h | ~10m3/h | ~5m3/h | ~4m3/h | ~3m3/h | ~2.8m3/h | 1350 | ||||

SZ303 | 150-210kg/h | ~15m3/h | ~7.5m3/h | ~6m3/h | ~4.5m3/h | ~4.2m3/h | 1900 | ||||

SZ304 | 200-280kg/h | ~20m3/h | ~10m3/h | ~8m3/h | ~6m3/h | ~5.6m3/h | 2500 | ||||

SZ351 | 100-120kg/h | ~10m3/h | ~5m3/h | ~4m3/h | ~3m3/h | ~2.4m3/h | 1100 | ||||

SZ352 | 200-240kg/h | ~20m3/h | ~10m3/h | ~8m3/h | ~6m3/h | ~4.8m3/h | 2100 | ||||

SZ353 | 300-360kg/h | ~30m3/h | ~15m3/h | ~12m3/h | ~9m3/h | ~7.2m3/h | 3100 | ||||

SZ354 | 400-480kg/h | ~40m3/h | ~20m3/h | ~16m3/h | ~12m3/h | ~9.6m3/h | 4100 | ||||

SZ401 | 130-160kg/h | ~13m3/h | ~6.5m3/h | ~5m3/h | ~4m3/h | ~3.2m3/h | 2200 | ||||

SZ402 | 260-320kg/h | ~26m3/h | ~13m3/h | ~10m3/h | ~8m3/h | ~6.4m3/h | 3500 | ||||

SZ403 | 390-480kg/h | ~39m3/h | ~19.5m3/h | ~15m3/h | ~12m3/h | ~9.6m3/h | 5500 | ||||

SZ404 | 520-640kg/h | ~52m3/h | ~26m3/h | ~20m3/h | ~16m3/h | ~12.8m3/h | 7000 | ||||

duringtransportation.

steel plate after long-term use.

disassemble.

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.