Shenzhou - Industrial automatic slag decanter centrifuge for liquid solid separation Centrifuge & Separator

State-of-the-art technologies are introduced and upgraded for the more efficient and stable manufacturing of the product. Industrial automatic slag decanter centrifuge for liquid solid separation functions perfectly in the application scenario(s) of Centrifuge & Separator. After the Industrial automatic slag decanter centrifuge for liquid solid separation was launched, most customers have given positive feedback, believing that this type of product meets their expectations for high-quality products. In the process of continuous entrepreneurial innovation, Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always adhere to the business philosophy of 'quality comes first'. We will grasp the opportunities of the times and always keep up with the industry trends. We believe that one day we will become one of the leading enterprises in the global market.

| Place of Origin: | China | Type: | Centrifuge |

| Product Type: | Paint | Condition: | New |

| Video outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | Hot Product 2019 | Warranty of core components: | 1 Year |

| Core Components: | PLC, Bearing, Motor | Brand Name: | LYSZ |

| Voltage: | 110V,220V,380V,440V,460V | Weight: | 1050 |

| Warranty: | 3 years | Key Selling Points: | Easy to Operate |

| Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company | Showroom Location: | None |

| Certification: | ISO,CE |

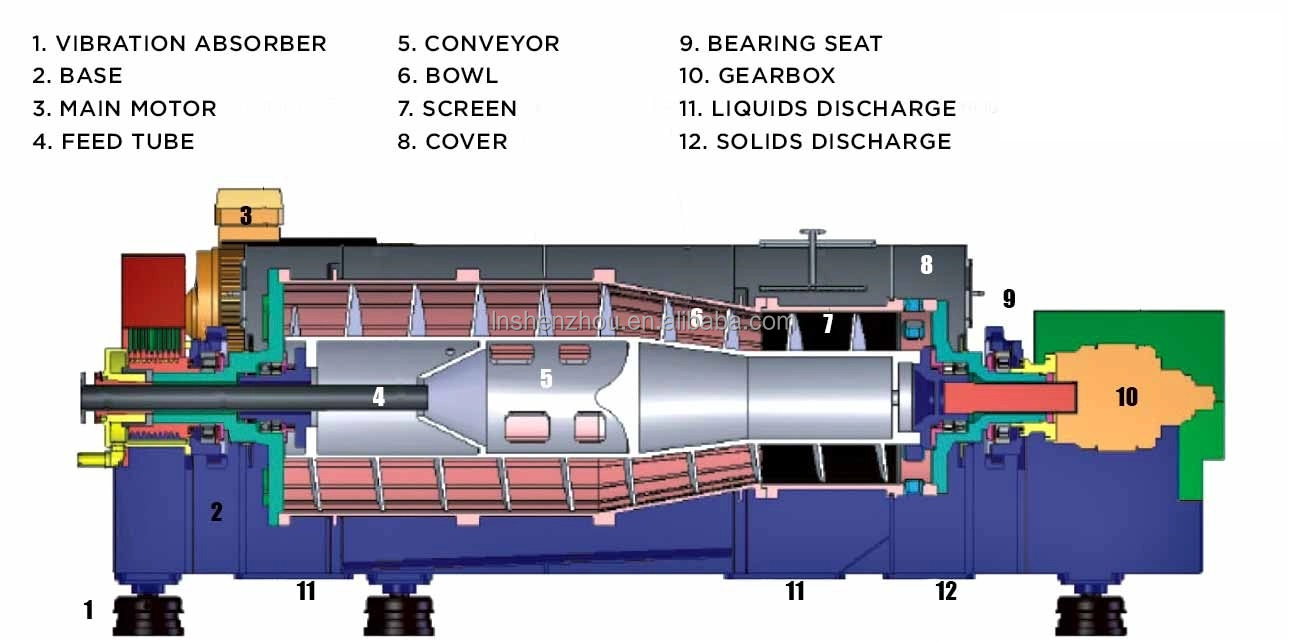

Parts of a Decanter Centrifuge

centrifugal forces that can be well beyond 3000 times greater than gravity. When subject to such forces, the denser solid

particles are pressed outwards against the rotating bowl wall, while the less dense liquid phase forms a concentric inner layer.

Different dam plates are used to vary the depth of the liquid – the so-called pond – as required. The sediment formed by the solidparticles is continuously removed by the screw conveyor, which rotates at a different speed than the bowl. As a result, the solidsare gradually “ploughed” out of the pond and up the conical “beach”. The centrifugal force compacts the solids and expels the surplus liquid. The dried solids then discharge from the bowl. The clarified liquid phase or phases overflow the dam plates situated at the opposite end of the bowl. Baffles within the centrifuge casing direct the separated phases into the correct flow path and prevent any risk of cross-contamination. The speed of the screw conveyor may be automatically adjusted by use of the variable frequency drive (VFD) in order to adjust to variation in the solids load.

Application:

pharmaceuticals and chemicals, etc.

1. Decanter centrifuge solid phase dehydration: dehydration effect for processing materials of solid particles.

2. Decanter centrifuge particle size classification: used in the removal of material of large diameter solid particles.

3. Decanter centrifuge liquid clarification: used for removing solid particles in the suspension liquid are clarified

Types Of Decanters

horizontal and conveyor centrifuges. The principle behind a decanter centrifuge is based on the theory of gravitational

separation. For example, if you fill a vessel with a mixture of mud and water, over time the weight of the mud will cause it to settle down at the base of the vessel. With the mud congealed at the bottom, the water will be forced upwards, creating a clear separation between the two.

Decanter Principles

A decanter centrifuge employs the same principles of gravitational force. However, unlike the glass mixture, the process is

expedited through the use of continuous rotation. In fact, rotation provides anywhere from 1000 to 4000 times the normal

gravitational force, reducing the time required for separation from hours to seconds.

Rotational Separation

The concept of rotational separation is similar to rides found at amusement parks and county fairgrounds. In these rides, placing yourself at an angle allows you to overcome the gravitational forces induced by rotation. Similarly, a decanter centrifuge is essentially a bowl tube that rotates at an extremely high speed. The bowl tube is equipped with an internal conveyor which moves in the same direction but at a different velocity.

How the Decanter Process Works:

* 1: The slurry is brought into the centrifuge through an intake pipe and onto a conveyor.

* 2: Utilizing an internal feed compartment, the conveyor moves the slurry through a nozzle into the bowl.

* 3: The bowl rotates at high speeds to induce centrifugal forces.

* 4: High speed rotation separates the solid material from the liquid in a matter of seconds.

* 5: The conveyor delivers the solid material upwards where it is discharged through a nozzle.

* 6: The solid material removed, the purified liquid is released from a separate output. The ability to purify a liquid makes

decanter centrifuges ideal for waste water treatment facilities. However, there are variety of industries for which such

centrifuges play an important role. Similar to other decanter equipment, centrifuges are simple to install and do not require a foundation to build upon. Their efficiency saves time and materials and is an essential component for many blue collar industries

What is a Decanter Centrifuge?

50% (v/v) solids from liquids on a continuous basis. Typical industrial decanter applications include Crude Oil Tank Bottoms; Waste Oil; Industrial Wastewater; Sludge Dewatering; Fish Meal; WVO/UVO De-Sludging; Paint Sludge; Rendering etc. etc.

How does it work?

done using centrifugal forces that can be well beyond 3000 times greater than gravity. When subject to such forces, the denser solid particles are pressed outwards against the rotating bowl wall, while the less dense liquid phase forms a concentric inner layer. Different dam plates are used to vary the depth of the liquid – the so-called pond – as required.

The sediment formed by the solid particles is continuously removed by the screw conveyor, which rotates at a different speed than the bowl. As a result, the solids are gradually “ploughed” out of the pond and up the conical “beach”. The centrifugal force compacts the solids and expels the surplus liquid. The dried solids then discharge from the bowl. The clarified liquid phase or phases overflow the dam plates situated at the opposite end of the bowl.

Horizontal Decanter Centrifuges Centrifuge World offers a wide variety of horizontal continuous cleaning decanter centrifuges which provide effective, low-maintenance solutions to continuous liquid clarifying and / or solids dewatering with advanced process and mechanical performance features.

Decanter centrifuges are extremely versatile and capable of adapting to varying throughput and process and material types. The machines are easy to adjust, require little operator attention, are relatively quiet and feature a small footprint.

Biodiesel Centrifuges: Centrifuge World offers a wide range of manual clean and self-cleaning biodiesel centrifuges process capacities ranging from 1 to 30-gpm.

Model | Diameter(mm) | Lenght(mm) | Max speed | L/D ratio | G-force | Capacity(m3/h) | Main motor power(Kw) | Weight(kg) | Dimension(mm) |

LW250*1000 | 250 | 1000 | 5000 | 4 | 2722 | 0.5-5 | 7.5 | 950 | 2120*1250*680 |

LW300*900 | 300 | 900 | 4200 | 3 | 2964 | 1-6 | 11 | 1160 | 2150*1300*900 |

LW300*1200 | 300 | 1200 | 4000 | 4 | 2784 | 2-6 | 11 | 1350 | 2450*1300*900 |

LW355*1160 | 355 | 1160 | 3600 | 3.3 | 2576 | 2-8 | 15 | 1400 | 2470*1350*830 |

LW355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 1800 | 2750*1350*830 |

LW400*1200 | 400 | 1200 | 3200 | 3 | 2294 | 3-12 | 18.5 | 1800 | 2730*1600*1080 |

LW400*1600 | 400 | 1600 | 3000 | 4 | 2016 | 3-15 | 22 | 2000 | 3130*1600*1080 |

LW450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 2500 | 3320*1700*1130 |

LW500*2000 | 500 | 2000 | 2800 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

LW530*1855 | 530 | 1855 | 2600 | 3.5 | 2006 | 5-38 | 55 | 4680 | 3885*1350*1600 |

LW530*2120 | 530 | 2120 | 2400 | 4 | 1709 | 5-40 | 55 | 4800 | 4150*1350*1600 |

LW550*2000 | 550 | 2200 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

LW650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

LW650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490-1510*1720 |

LW720*2160 | 720 | 2160 | 2000 | 3 | 1612 | 7-80 | 120 | 6000 | 5200*1600*1800 |

LW720*2880 | 720 | 2880 | 2000 | 4 | 1306 | 7-90 | 120 | 8000 | 3100*1600*1800 |

LW800*2400 | 800 | 2400 | 1800 | 3 | 1451 | 20-100 | 150 | 12000 | 5820*2000*1300 |

LW800*3200 | 800 | 3200 | 1800 | 4 | 1451 | 20-120 | 150 | 13000 | 7100*2000*1300 |

* ALL STAINLESS STEEL CENTRIFUGE BOWL COMPONENTS

* SUITABLE FOR UNATTENDED OPERATION

* PRESSURIZED LIGHT / HEAVY PHASE LIQUID DISCHARGE

* BACK PRESSURE REGULATING VALVES FOR MORE ADJUSTABLE SEPARATION CONTROL

* ELECTRICAL CONTROL PANEL AND AUTOMATION

* XP MOTOR STANDARD (REQUIRES THREE PHASE POWER)

* AUTOMATIC SLUDGE DISCHARGE AND WATER HARNESS ON SELF CLEANING UNIT

* BASE PLATE, TOOLS, INSTRUCTION MANUAL INCLUDED

* Options and Accessories

* FEED PUMP AND INLET STRAINER

* PROCESS HEAT EXCHANGER

* SLUDGE TANK AND TRANSFER PUMP

* COMPLETE MODULAR SYSTEM SKID SOLUTIONS

* Benefits

* FULL FACTORY WARRANTY PROTECTS YOUR INVESTMENT

* PROCESS AND PRE-INSTALLATION CONSULTING

* INSTALLATION, OPERATIONAL TRAINING, MAINTENANCE, & OPTIMIZATION

* TANKS, FILTERS, MIXERS, PUMPS, AND SYSTEM AUTOMATION

* ANNUAL MAINTENANCE PROGRAMS, ON-SITE FIELD SERVICING OR FACTORY SERVICING AT ONE OF OUR NATIONAL LOCATIONS

* SPECIALIZED INDUSTRY EXPERTISE AND RELATED ENGINEERING, CONTROLS, SERVICE AND SUPPORT

We are based in Liaoning, China, start from 2018,sell to South America(12.00%),Southeast Asia(10.00%),Northern Europe(10.00%),Southern Europe(10.00%),Domestic Market(10.00%),South Asia(8.00%),Central America(6.00%),North America(5.00%),Eastern Europe(5.00%),Africa(5.00%),Oceania(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Mid East(4.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Centrifuge,Separator,Packing machine,Drying machine,Filling & Sealing machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian