Shenzhou - New Design Automatic Commercial 100Kg Potato Chips Making Machine Food Machine

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd has been focusing on improving technologies to develop new products on a regular basis. We have successfully made New Design Automatic Commercial 100Kg Potato Chips Making Machine launch to the public as scheduled. With its new features, Decanter centrifuge,Disc Centrifuge,Tubular Centrifuge,Plate Centrifuge is expected to lead the industry trend. We pride ourselves on our personalized and efficient service. The design of New Design Automatic Commercial 100Kg Potato Chips Making Machine is carefully thought to fit the market trend, keeping us one step ahead of other manufacturers. It is made of raw materials that have been tested by our QC inspectors. By processing those materials with improved technologies, we ensure the product has so many advantages .Decanter centrifuge,Disc Centrifuge,Tubular Centrifuge,Plate Centrifuge will bring convenience and benefits to customers.

| Condition: | New | Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company |

| Showroom Location: | None | Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided | Marketing Type: | New Product 2021 |

| Warranty of core components: | 1 Year | Core Components: | PLC, Engine, Bearing, Gearbox, Pressure vessel, Gear, Pump |

| Brand Name: | LYSZ | Place of Origin: | China |

| Voltage: | 220V | Power: | 4KW |

| Dimension(L*W*H): | 1000*500*800mm | Weight: | 400 KG |

| Warranty: | 1 Year | Application fields: | Vegetable processing plant, Winery, Cannery, Flour mill, Commercial catering, Cooking oil factory, Meat processing plants, Seasoning plant, Dairy products factory, Fruit processing plant, Bakery, Snack food factory, Frozen food Factory, Beverage Factory |

| Machinery Function: | potato chips french fries making production line | Raw material: | Milk, Corn, Fruit, Wheat, Nuts, Soybean, Flour, Vegetables, Water |

| Output product name: | Potato Crisps Processing Machinery | Key Selling Points: | Easy to Operate |

2. All equipment are made of SUS304,

3. Heating method: Electric heating, Gas heating or Diesel heating (equipped with Riello or Baltur burner), etc.

4. The size of french fries and the thickness of potato chips are adjustable.

5. For french fries line, we have special equipment to remove the unqualified fries.

6. With special designed fryer, quick heating and energy saving, enabled good performance.

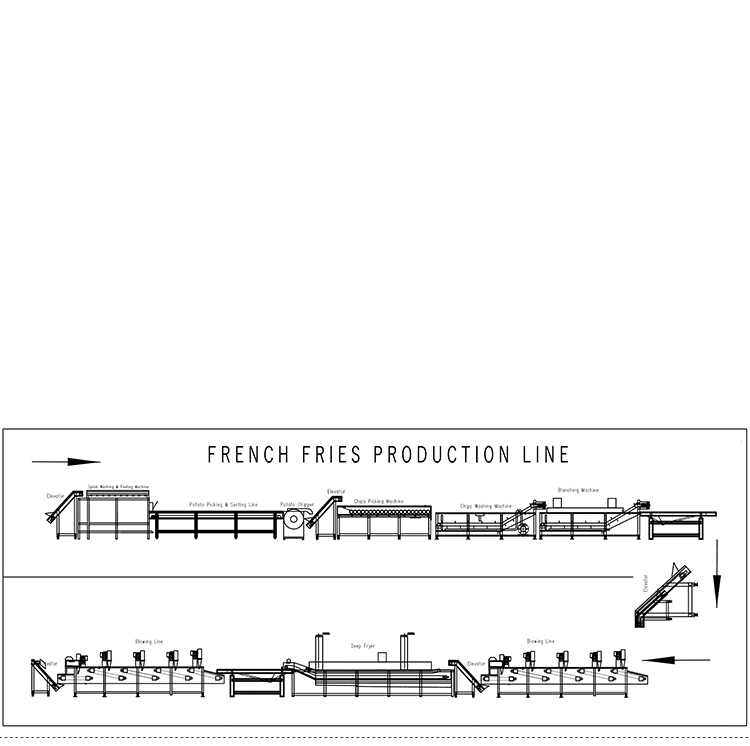

No. | Machine Name | Function |

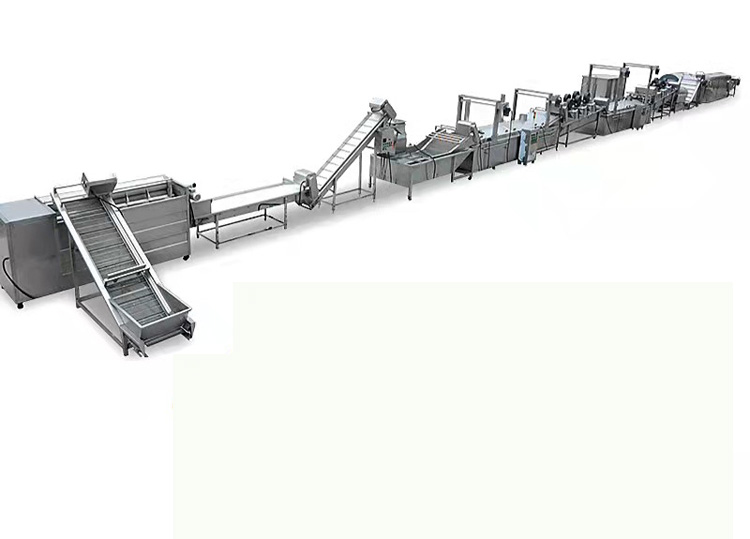

1 | Elevating Conveyor | For elevating and conveying fresh potatoes into the next washing peeling machine |

2 | Potato Washing Peeling Machine | Thoroughly washing and peeling the potatoes |

3 | Sorting Conveyor | For manually disposing the uncleaned places and selecting the defective potatoes |

4 | Chips Slicing Machine | Cutting the potatoes into chips, the thickness is adjustable |

5 | Bubble Washing Machine | Through high pressure waterflow and water bubbles to impact and scrub the fries to wash off the starch |

6 | Blanching Machine | Through 60-95 degree hot water blanching to inhibit the activity of the enzyme and maintains the original vivid color of the chips |

7 | Air Drying Machine | Through high pressure wind blowing for pre-cooling and removing the excess water in short time, effectively prevent the fried oil jumped phenomenon |

8 | Elevating Conveyor | For elevating and conveying the fries into next fryer machine |

9 | Continuous Fryer | For chips frying |

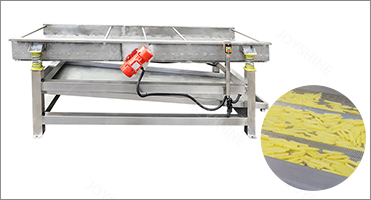

10 | Vibrating Deoiling Machine | Through vibration to achieve deoiling purpose, and also to convey the fries uniformly to next machine |

11 | Pre-Cooling Machine | Through high pressure wind blowing to cool down the chips |

12 | Elevating Conveyor | For elevating the chips to next seasoning machine |

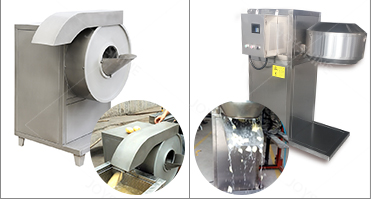

13 | Seasoning Machine | For seasoning the chips with different flavors |

14 | Packing Machine | For packing the finished potato chips |

We are based in Liaoning, China, start from 2018,sell to North America(30.00%),South America(10.00%),Southeast Asia(10.00%),South Asia(7.00%),Eastern Europe(5.00%),Oceania(5.00%),Mid East(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Central America(5.00%),Northern Europe(5.00%),Southern Europe(5.00%),Africa(3.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Separator,Centrifuge,Packing & Filling,Drying,Tabling Machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian